Prediction method and system for temperature field of nanometer core-shell particles

A nano-core-shell and prediction method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as simulation result distortion, material gasification, and high melting pool temperature, so as to reduce size error and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The object of the present invention is to provide a method and system for predicting the temperature field of nano-core-shell particles, so as to improve the accuracy of temperature field prediction of nano-core-shell particles.

[0054] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

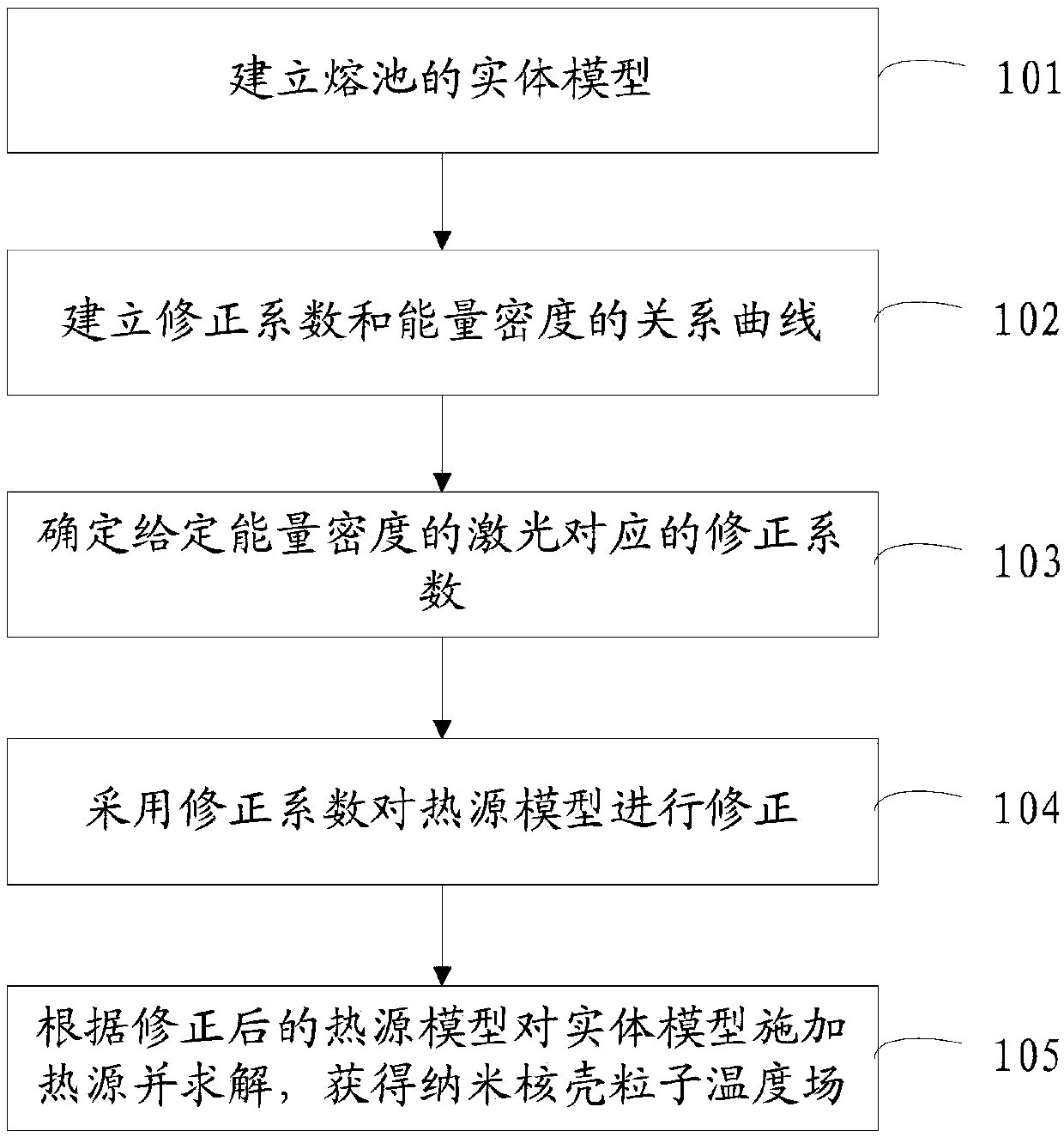

[0055] Such as figure 1 As shown, the present invention provides a method for predicting the temperature field of nano-core-shell particles, and the method for predicting comprises the following steps:

[0056] Step 101, establishing a solid model of the molten pool according to the actual size of the molten pool;

[0057]Step 102, based on the solid model of the molten pool, establish a relationship curve between correction coefficient and energy density;

[0058] Step 103, determining the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com