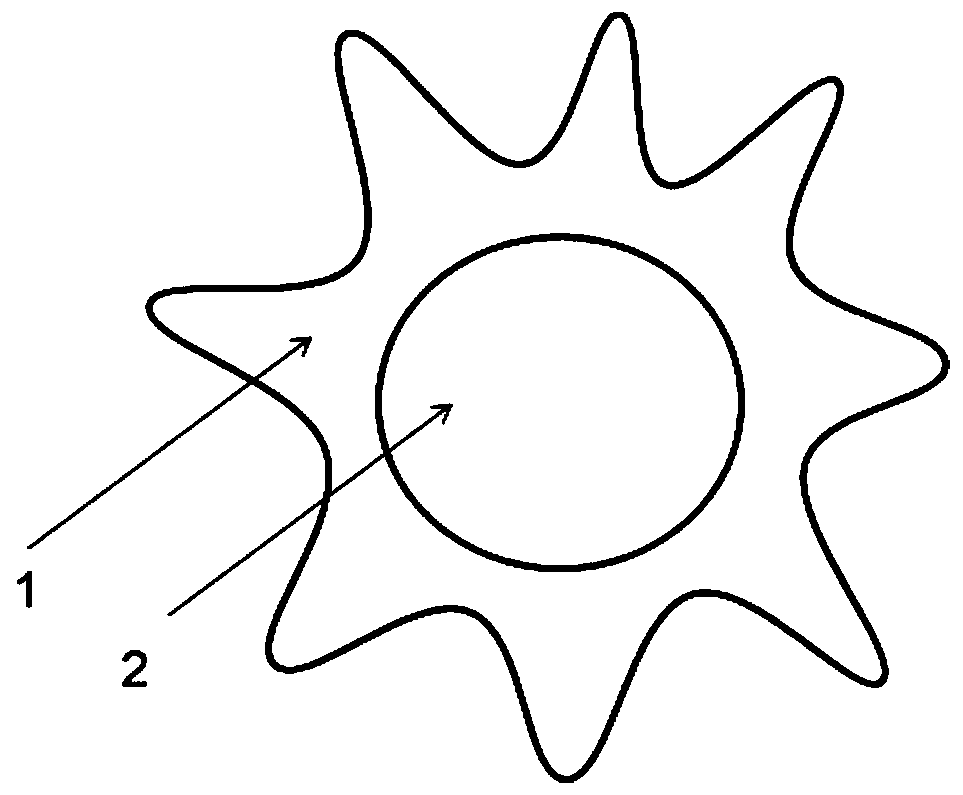

Preparation method of hollow fiber solid oxide fuel cell with petal-shaped cross section

A solid oxide, fuel cell technology, used in fuel cells, circuits, electrical components, etc., can solve the problems of reduced battery output performance, small external surface area, and reduced effective area, etc., to improve output power, promote surface reaction, increase The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of the petal-shaped hollow fiber solid oxide fuel cell comprises the following steps:

[0047] (1) Preparation of polymer solution

[0048] Dissolve 12.5g of polyethersulfone, 0.1g of polyacrylamide, and 1g of polyvinylpyrrolidone in 50g of N,N-dimethylformamide-d 7 , to obtain a polymer solution; wherein polyacrylamide is added in the form of a mixed solution: 0.1 g of polyacrylamide is dissolved in 3 g of water, and then added to 10 g of ethylene glycol to form a mixed solution.

[0049] (2) Preparation of ceramic-polymer casting solution

[0050] 150g La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ Add the cathode ceramic powder to 75.6g of the polymer solution obtained in step (1), and fully stir for 24 hours to make it completely and evenly dispersed in the polymer solution to form a ceramic-polymer casting solution with a viscosity of 26500MPa·s ; The average particle size of the ceramic powder is 1 μm.

[0051] (3) Preparation of a hollow fiber c...

Embodiment 2

[0058] The preparation method of the petal-shaped hollow fiber solid oxide fuel cell comprises the following steps:

[0059] (1) Preparation of polymer solution

[0060] Dissolve 12.5g polyethersulfone, 0.5g polyacrylamide, 2g polyvinyl butyral in 50g N,N-dimethylformamide-d 7 , to obtain a polymer solution; wherein polyacrylamide is added in the form of a mixed solution: 0.5 g of polyacrylamide is dissolved in 5 g of water, and then added to 20 g of ethylene glycol to form a mixed solution.

[0061] (2) Preparation of ceramic-polymer casting solution

[0062] 145.5g La 0.6 Sr 0.4 CoO 3-δ The cathode ceramic powder was added to 79g of the polymer solution obtained in step (1), and stirred for 30 hours to make it completely and evenly dispersed in the polymer solution to form a ceramic-polymer casting solution with a viscosity of 28400MPa·s; The average particle size of the ceramic powder is 4 μm.

[0063] (3) Preparation of a hollow fiber cathode support embryo body with...

Embodiment 3

[0070] The preparation method of the petal-shaped hollow fiber solid oxide fuel cell comprises the following steps:

[0071] (1) Preparation of polymer solution

[0072] Dissolve 12.5g polysulfone, 0.5g polyacrylamide, 4g polyammonium methacrylate in 50g N,N-dimethylformamide-d 7 , to obtain a polymer solution; wherein polyacrylamide is added in the form of a mixed solution: 0.5 g of polyacrylamide is dissolved in 5 g of water, and then added to 25 g of ethylene glycol to form a mixed solution.

[0073] (2) Preparation of ceramic-polymer casting solution

[0074] 175g Ni 0.8 Fe 0.2 o x The anode ceramic powder is added to 95g of the polymer solution obtained in step (1), and fully stirred for 30 hours to make it completely and evenly dispersed in the polymer solution to form a ceramic-polymer casting solution with a viscosity of 28500MPa·s; The average particle size of the ceramic powder is 5 μm.

[0075] (3) Preparation of hollow fiber anode support embryo body with pet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

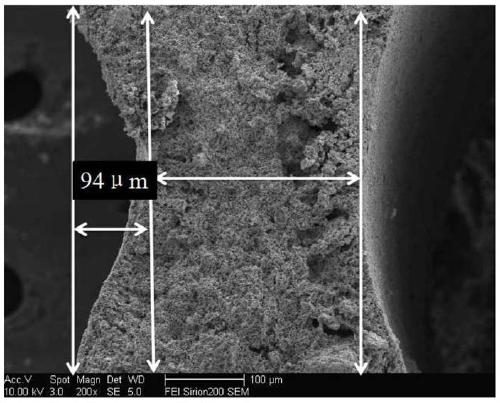

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com