Roll paper conveying control device based on tobacco molding equipment

A forming equipment and conveying control technology, which is applied in the direction of tobacco, winding rods, e-liquid filter elements, etc., can solve the problems of easy-to-break roll paper, achieve stable supply, stable and effective unwinding, and eliminate easy-to-break problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

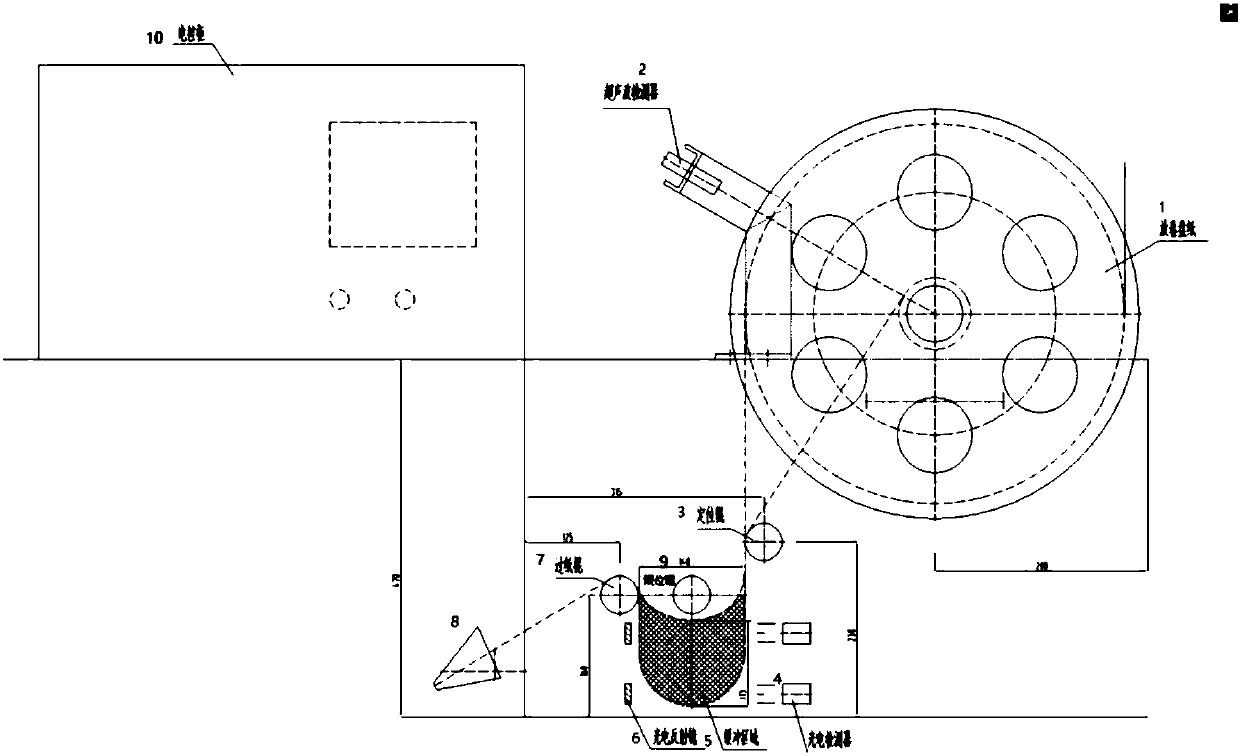

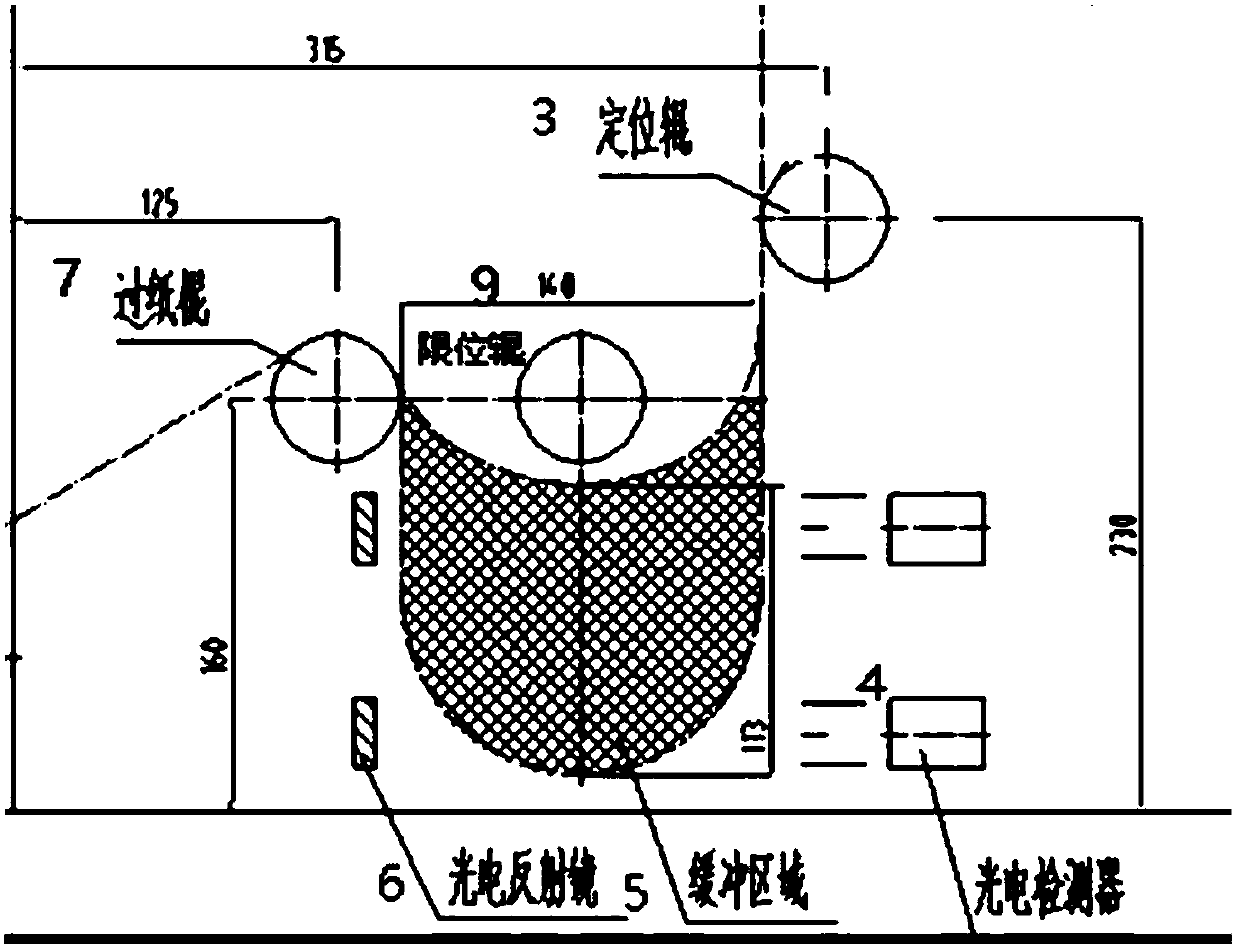

[0014] see figure 1 The rotating shaft of the unwinding reel 1 is equipped with a servo motor, and an ultrasonic detector 2 is installed on the edge of the unwinding reel 1. The detector detects the real-time changing radius of the paper reel, and then calculates the value according to the speed signal of the original machine. The angular velocity of the servo motor rotating at the linear velocity, and the rotational speed of the servo motor is controlled according to the angular velocity. Between the positioning roller 3 and the paper passing roller 7 under the unwinding coil 1, a buffer area 5 with one end allowing the roll paper to sag naturally ensures the flexibility of the original machine’s operating speed and the unwinding speed, and the shredded tobacco will not bear the burden during operation. Excessive pull. The single-chip microcomputer configured in the electric control cabinet 10, the interface of the single-chip microcomputer corresponds to the servo motor con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com