Coke oven flue gas desulfurization, dust removal and denitrification integrated system

A denitrification catalyst and denitrification technology, applied in chemical instruments and methods, dispersed particle filtration, dispersed particle separation, etc., can solve problems such as wear of alkali metal, catalyst blockage, complex composition, etc., to achieve safe operation, prolong service life, temperature field evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is illustrated in conjunction with the following examples.

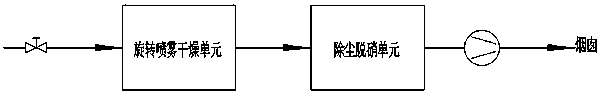

[0041] An integrated system for desulfurization, dust removal and denitrification of coke oven flue gas, comprising a rotary spray drying unit and a dust removal and denitrification unit. The raw flue gas is desulfurized by rotary spray semi-dry method in the rotary spray drying unit to obtain desulfurized flue gas. The desulfurized flue gas enters the dust removal and denitrification unit for bag dust removal, and then performs selective catalytic reduction and denitrification to obtain exhaust gas that meets the emission standards.

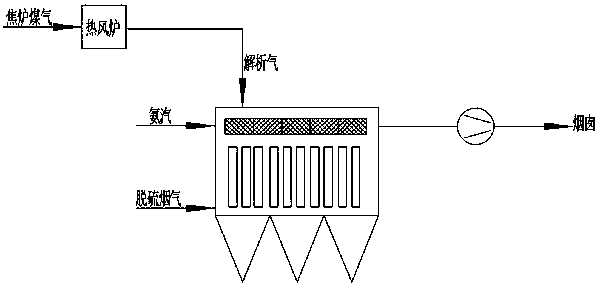

[0042] The dust removal and denitrification unit includes: an integrated dust removal and denitrification device and an ammonia injection device. The dust removal and denitrification integrated device integrates the bag dust removal process and the selective catalytic reduction denitrification process; the desulfurization flue gas enters the dust removal Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com