Design method of heavy hammer piece progressive die

A design method and progressive die technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large number of molds, low production efficiency, low efficiency, etc., to improve product precision, increase production efficiency, and achieve huge The effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

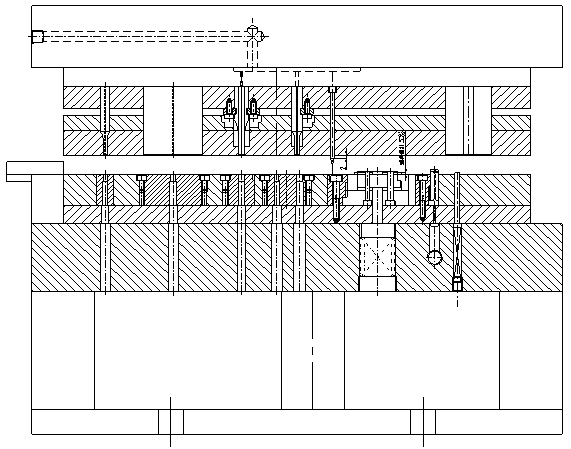

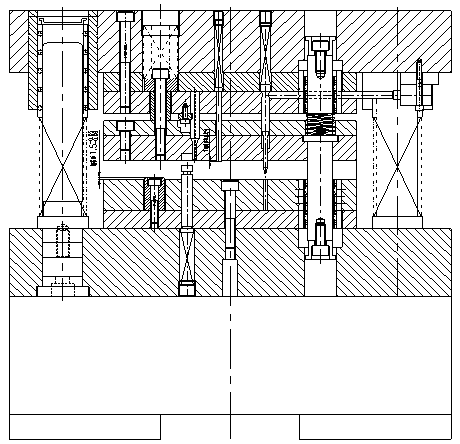

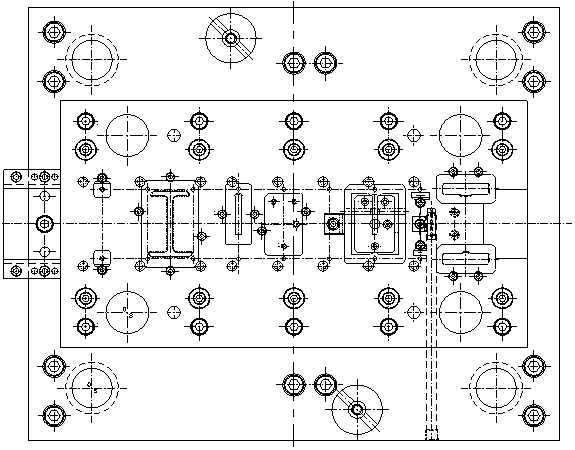

[0046]This embodiment provides a design method for the progressive die of the heavy hammer, which is characterized in that: the progressive die is designed as a single row of nine steps, that is, punching the process hole → guiding → trimming → punching grooves → punching three circles Hole → empty step → punching burr → embossing → drop shape; the working parts adopt a quick-change mosaic structure, which is convenient for processing, adjustment and replacement of inserts;

[0047] Due to the large output of parts and the high precision of the mold, in order to prevent the mold from deforming during use, the upper and lower mold base plates of the mold are all quenched and tempered with 45 steel; the concave plate is made of Cr12MoV mold steel, and the quenching hardness reaches 56-60HRC; other punches are fixed The plate, stripper plate and backing plate are all made of CrWMn die steel, with a quenching hardness of 56-58HRC; the punch and die inserts are made of wear-resistan...

Embodiment 2

[0080] This embodiment provides a design method for the progressive die of the heavy hammer, which is characterized in that the progressive die is designed as a single row of nine steps, that is, punching the process hole → guiding → trimming → punching grooves → punching three circles Hole → empty step → punching burr → embossing → drop shape; the working parts adopt a quick-change mosaic structure, which is convenient for processing, adjustment and replacement of inserts;

[0081] Due to the large output of parts and the high precision of the mold, in order to prevent the deformation of the mold during use, the upper and lower mold seat plates of the mold are all quenched and tempered with 45 steel; the concave plate is made of Cr12MoV mold steel, and the quenching hardness reaches 56-60HRC; other punches are fixed The plate, stripper plate and backing plate are all made of CrWMn die steel with a quenching hardness of 56-58HRC; punches and die inserts are made of wear-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quenching hardness | aaaaa | aaaaa |

| Quenching hardness | aaaaa | aaaaa |

| Quenching hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com