Cutter replaceable ultrasonic press polishing device for lathe

An optical device and ultrasonic technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of automatic tool change, complex ultrasonic system, and large amount of cutting fluid, etc., to improve calendering Good effect, cooling and lubricating effect, the effect of using a small amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

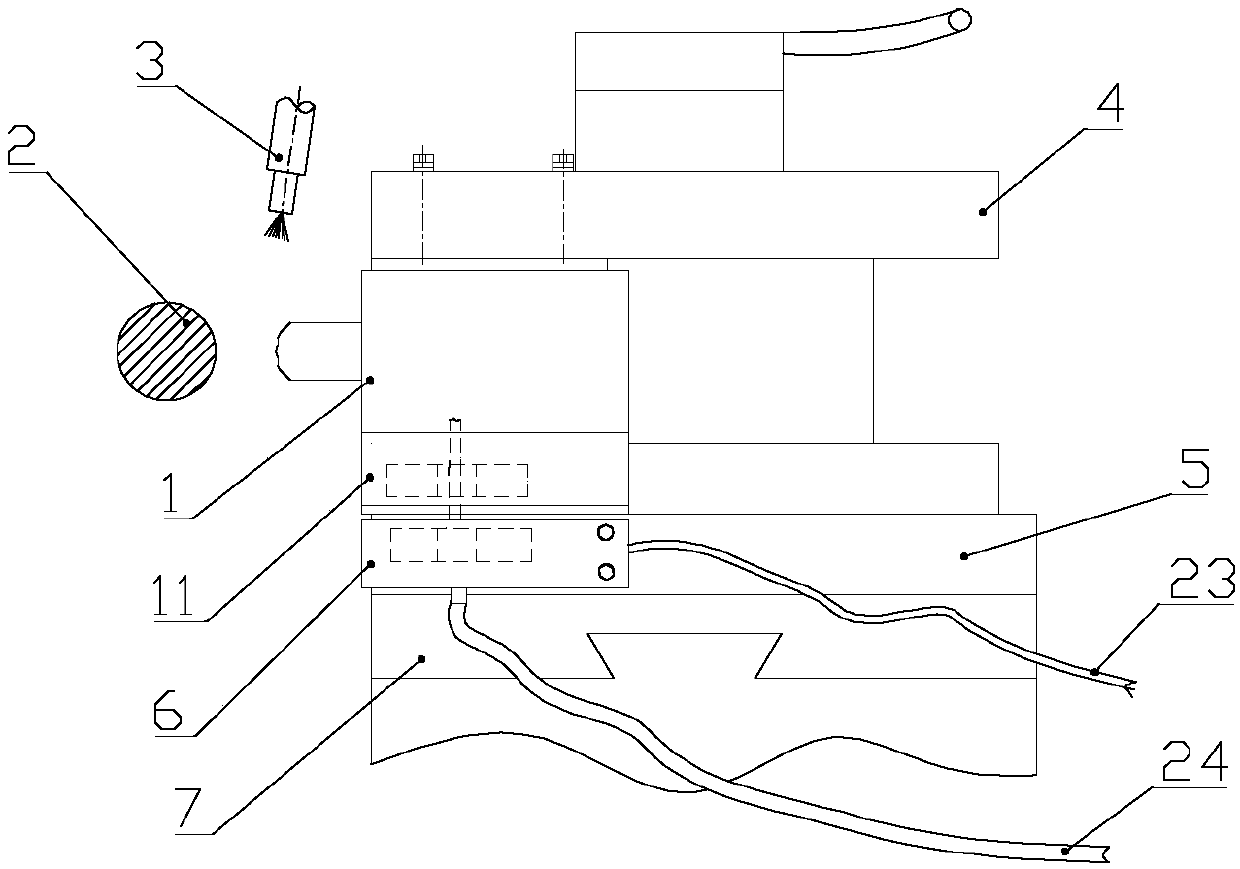

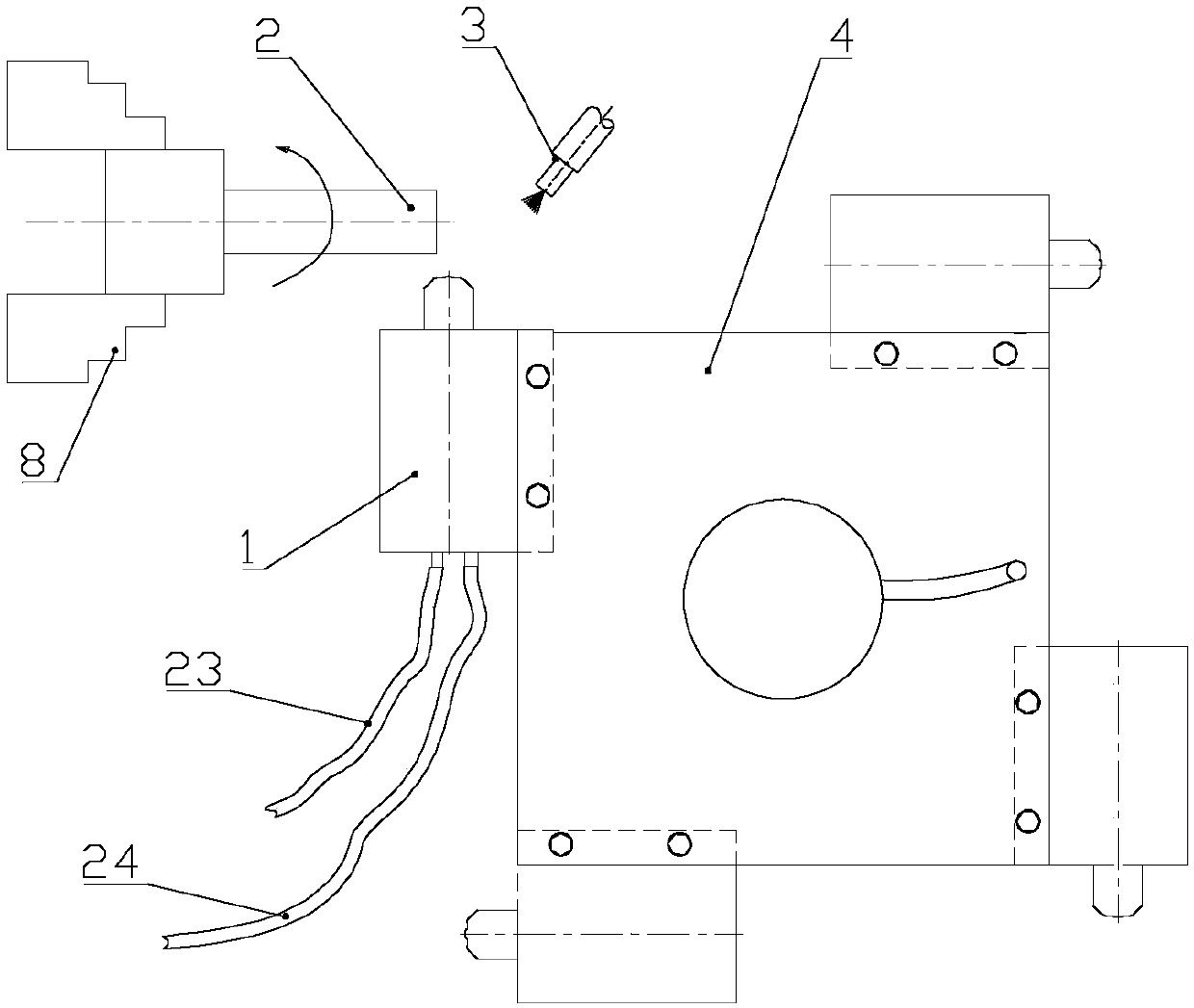

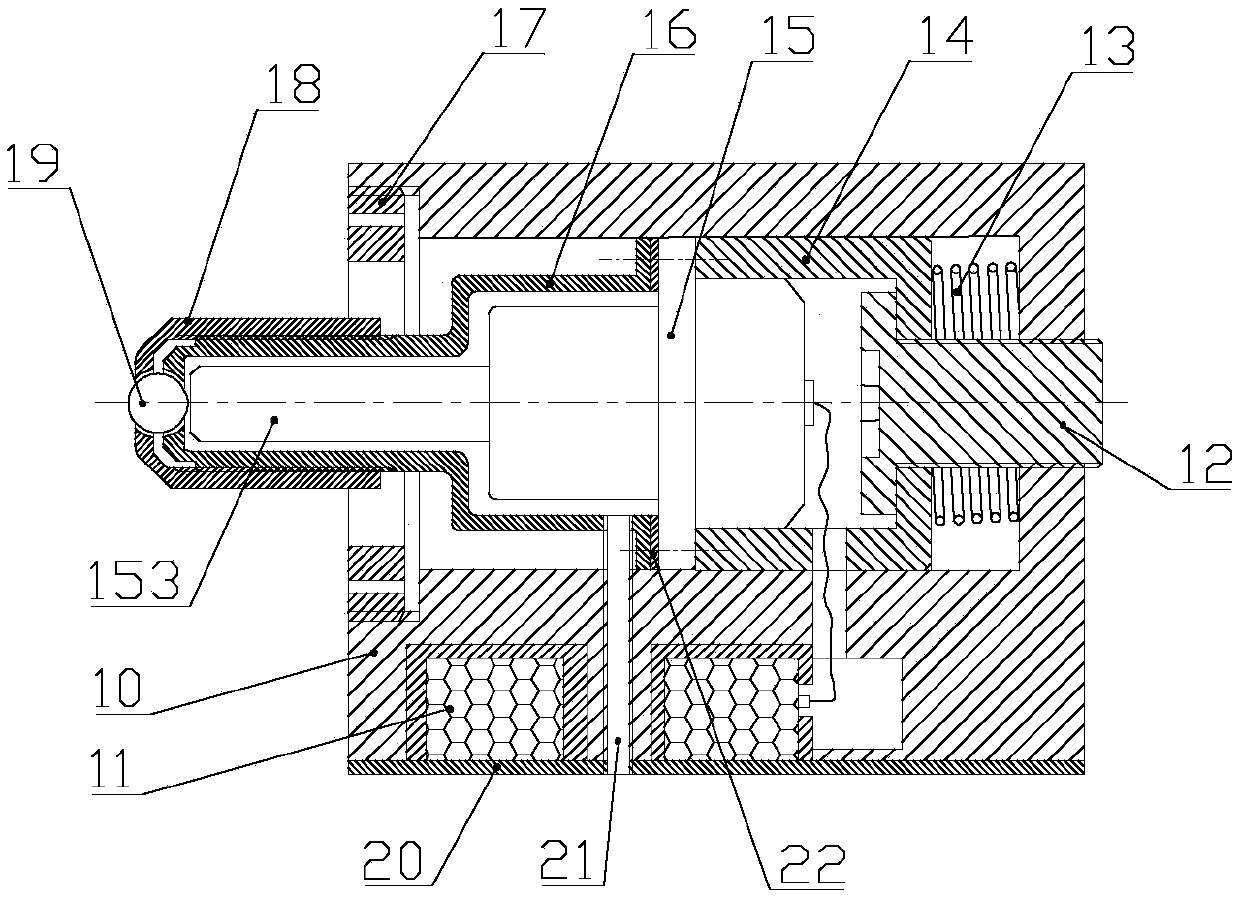

[0026] Such as figure 1 , image 3 , Figure 4 As shown, the tool-changeable ultrasonic calendering device for lathes includes an ultrasonic calendering knife 1, an external high-pressure oil mist nozzle 3, a built-in high-pressure oil mist nozzle 21, an ultrasonic wireless transmitter 6, and an oil mist connecting pipe 24, etc. The ultrasonic calendering knife 1 is installed on the rotatable tool holder 4 of the lathe through the clamping block 101 on the housing 10, and its specific position is the position where the turning tool is installed on the tool holder 4. The clamping block 101 is fixedly clamped on the tool holder 4; the ultrasonic wireless transmitter 6 is installed on the side of the tool holder 5 through screws, the tool holder 5 is fixedly connected to the carriage 7, and the workpiece 2 is clamped by the chuck 8 On the lathe spindle; in the housing 10 of the ultrasonic calendering knife 1, an ultrasonic wireless receiver 11 and an ultrasonic transducer 15 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com