A Narrow Deep Cavity Track Type Multi-Power Head Processing Device

A multi-power head and processing device technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of difficult processing of narrow and long deep cavity components, large volume of multi-axis equipment, etc., to avoid vertical axis conversion errors, high High-quality, efficient and high-precision machining to ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

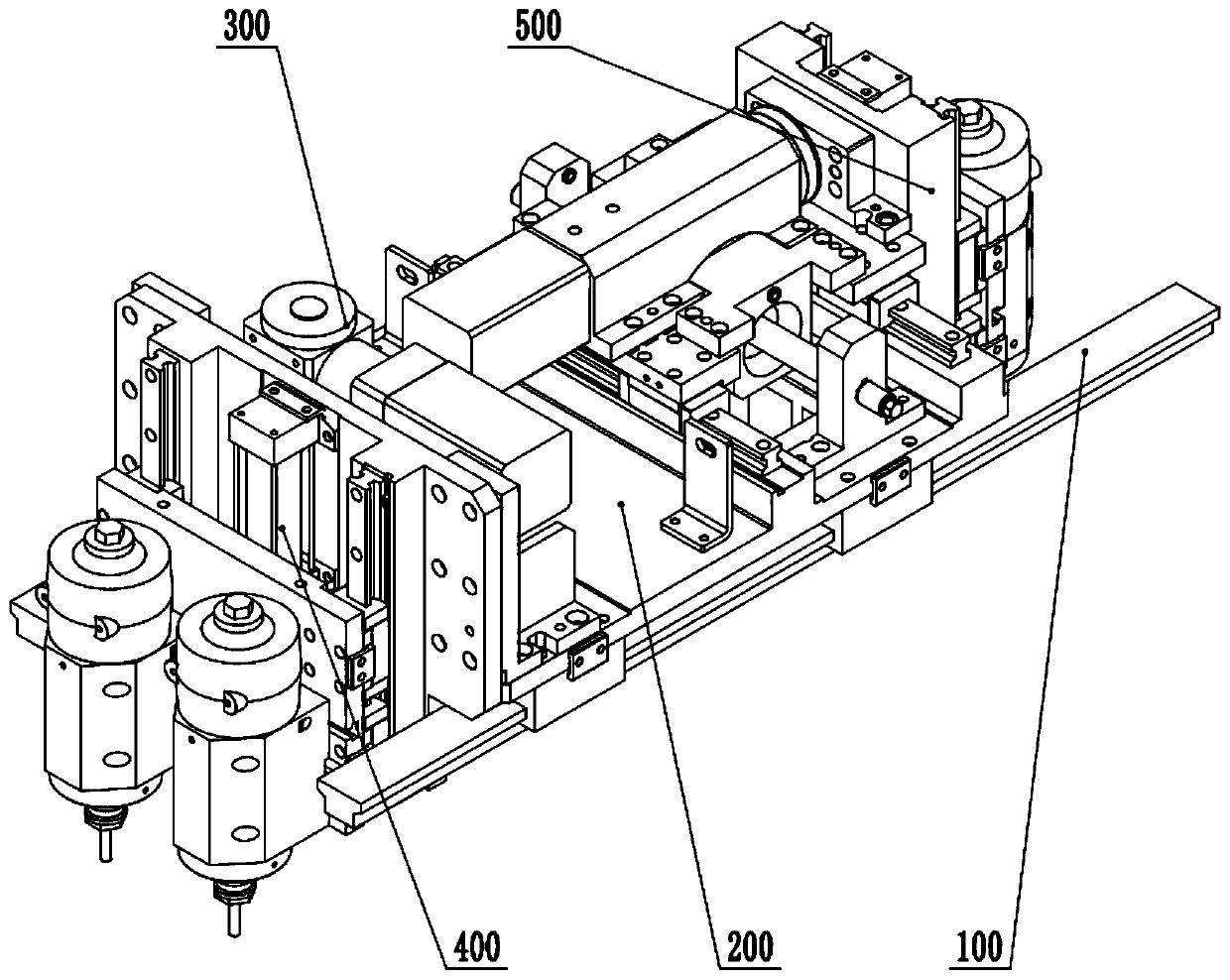

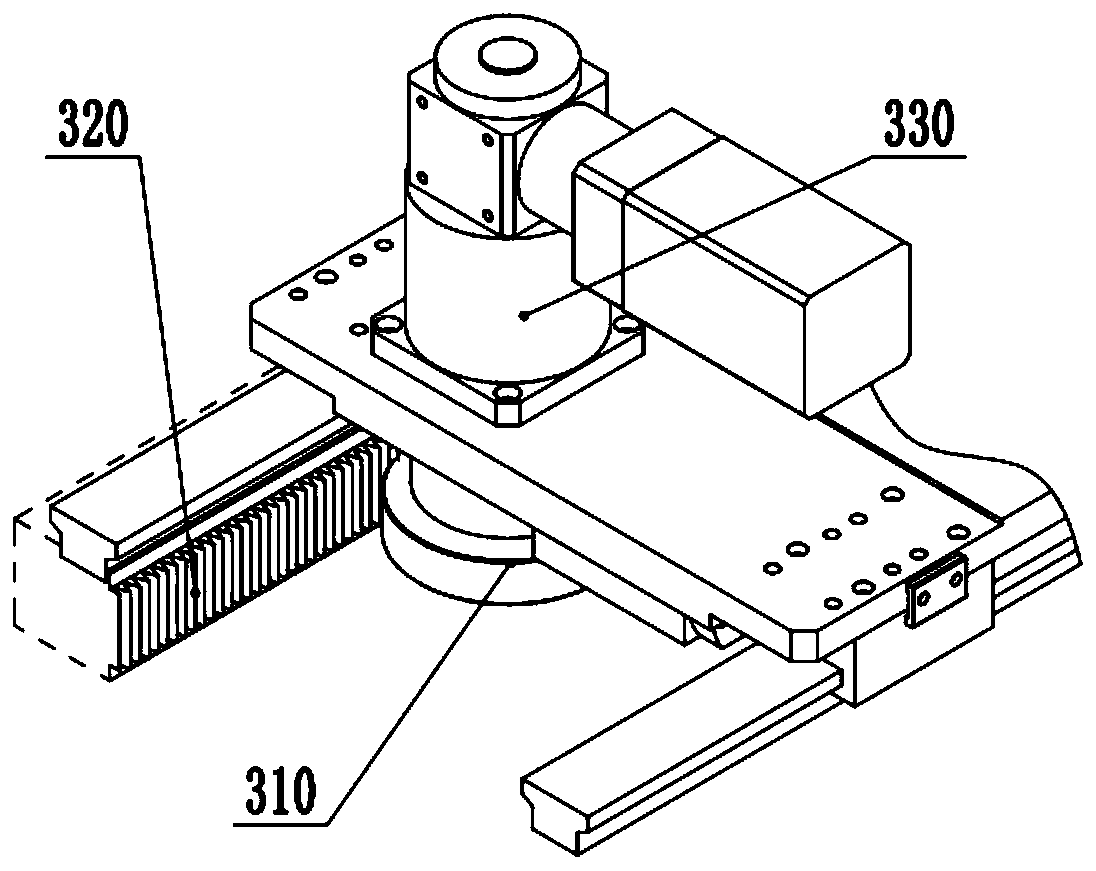

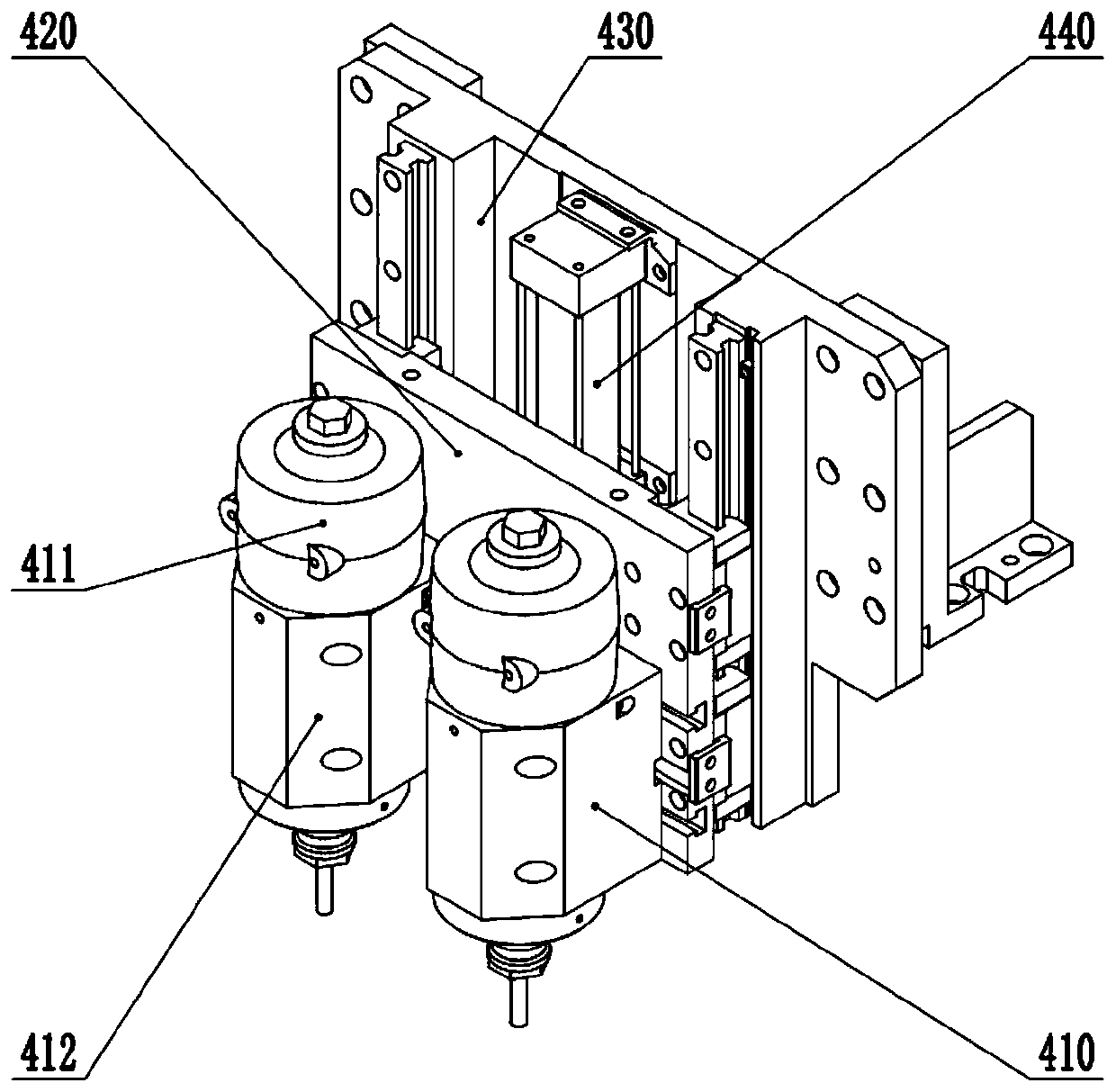

[0026] Such as Figure 1-4 As shown, a narrow and deep cavity track-type multi-power head processing device includes a guide rail 100, a base frame 200, a longitudinal axis shifting and feeding mechanism 300 and a processing module; the base frame 200 is connected to the guide rail 100 through a sliding rail block, The longitudinal axis shifting and feeding mechanism 300 and the processing module are both installed on the chassis 200; the longitudinal axis shifting and feeding mechanism 300 cooperates with the rack 320 on the inner side of the guide rail 100 on the machine tool to achieve the longitudinal accuracy of the processing module. Move; the longitudinal axis shifting and feeding mechanism 300 participates in multi-axis linkage to achieve precise interpolation movement of the processing module.

[0027] The processing mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com