Sound insulation trim panel for automobiles

A technology for interior trim panels and sound insulation panels, which is applied in the field of automotive interior panels and sound insulation interior panels for automobiles. It can solve the problems of affecting the comfort of passengers in the car, poor sound insulation and noise reduction effects, and poor fracture resistance. Improve the insulation and absorption capacity, good use effect, and good fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

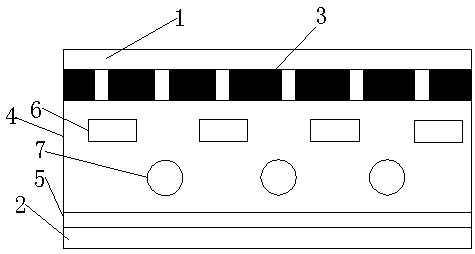

[0011] As shown in the figure, a sound-insulating interior panel for automobiles includes a plastic plate 1 on the surface, a sound-insulating structure in the middle, and an aluminum plate 2 at the bottom. The sound-insulating structure is a three-layer structure, including a titanium honeycomb plate connected to the plastic plate 3. The double-effect sound insulation board 4 in the middle, and the sound insulation felt 5 connected with the aluminum plate; the double-effect sound insulation board includes an upper sound insulation cavity and a lower sound insulation cavity, and the upper sound insulation cavity includes several evenly distributed rectangular cavities 6, and the lower layer The soundproof cavity includes several uniformly distributed circular cavities 7, and rectangular cavities and circular cavities are alternately distributed.

[0012] The surface layer of the plastic plate is provided with an activated carbon fiber layer.

[0013] The surface of the activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com