Preparation method of nanoscale sound insulation glass material

A technology of sound insulation glass and nanomaterials, applied in the field of glass material preparation, can solve problems such as insufficient sound insulation glass, and achieve the effects of improving sound insulation, high sound insulation performance, and excellent sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

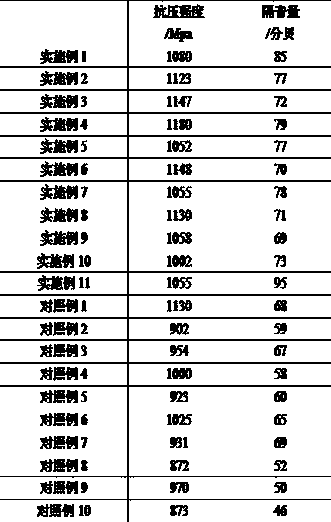

Examples

Embodiment 1

[0015] A preparation method of nano-scale sound-insulating glass material, comprising the following steps:

[0016] Step 1. In a warm water bath at 30°C, accurately weigh 4 parts of cetyltrimethylammonium bromide and dissolve it in a mixed solution of 7.8 parts of ethanol and 16.5 parts of deionized water to form a mixture containing cetyltrimethylammonium bromide. A mixture of ammonium bromide;

[0017] Step 2. Add 3 parts of ammonia water with a concentration of 12mol / L to the mixture and stir for 10 minutes, then add 21 parts of Cu-BTC-SiO 2 Nanomaterials and 3 parts of tetraethyl silicate were stirred for 30 minutes, the solution turned into a white suspension, then 2.3 parts of triethyl phosphate was added, stirred for 30 minutes, and then 4.8 parts of calcium nitrate tetrahydrate was accurately weighed and stirred for 1 minute; finally added 5.8 parts of lanthanum nitrate hexahydrate, stirred for 12 hours, filtered with suction, washed 3 times with deionized water and a...

Embodiment 2

[0026] Step 1. In a warm water bath at 30°C, accurately weigh 4 parts of cetyltrimethylammonium bromide and dissolve it in a mixed solution of 7.8 parts of ethanol and 16.5 parts of deionized water to form a mixture containing cetyltrimethylammonium bromide. A mixture of ammonium bromide;

[0027] Step 2. Add 16 parts of ammonia water with a concentration of 12mol / L to the mixture and stir for 10 minutes, then add 28 parts of Cu-BTC-SiO 2 Nanomaterials and 3 parts of tetraethyl silicate were stirred for 30 minutes, the solution turned into a white suspension, then 2.3 parts of triethyl phosphate was added, stirred for 30 minutes, and then 4.8 parts of calcium nitrate tetrahydrate was accurately weighed and stirred for 1 minute; finally added 5.8 parts of lanthanum nitrate hexahydrate, stirred for 12 hours, suction filtered, washed with deionized water and absolute ethanol three times each to obtain a white precipitate; the rest of the preparation was the same as in Example 1. ...

Embodiment 3

[0029] Step 1. In a warm water bath at 30°C, accurately weigh 4 parts of cetyltrimethylammonium bromide and dissolve it in a mixed solution of 7.8 parts of ethanol and 16.5 parts of deionized water to form a mixture containing cetyltrimethylammonium bromide. A mixture of ammonium bromide;

[0030] Step 2. Add 3 parts of ammonia water with a concentration of 12mol / L to the mixture and stir for 10 minutes, then add 35 parts of Cu-BTC-SiO 2 Nanomaterials and 6 parts of tetraethyl silicate were stirred for 30 minutes, the solution turned into a white suspension, then 2.3 parts of triethyl phosphate was added, stirred for 30 minutes, and 4.8 parts of calcium nitrate tetrahydrate was accurately weighed and stirred for 1 minute; finally added 5.8 parts of lanthanum nitrate hexahydrate, stirred for 12 hours, suction filtered, washed with deionized water and absolute ethanol three times each to obtain a white precipitate; the rest of the preparation was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com