Polyurethane self-leveling floor material and preparation method thereof

A technology of polyurethane and flat ground, which is applied in the field of polyurethane materials, can solve problems such as easy shrinkage cavities, achieve the effects of reducing shrinkage cavities, excellent performance, and improving hardness and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

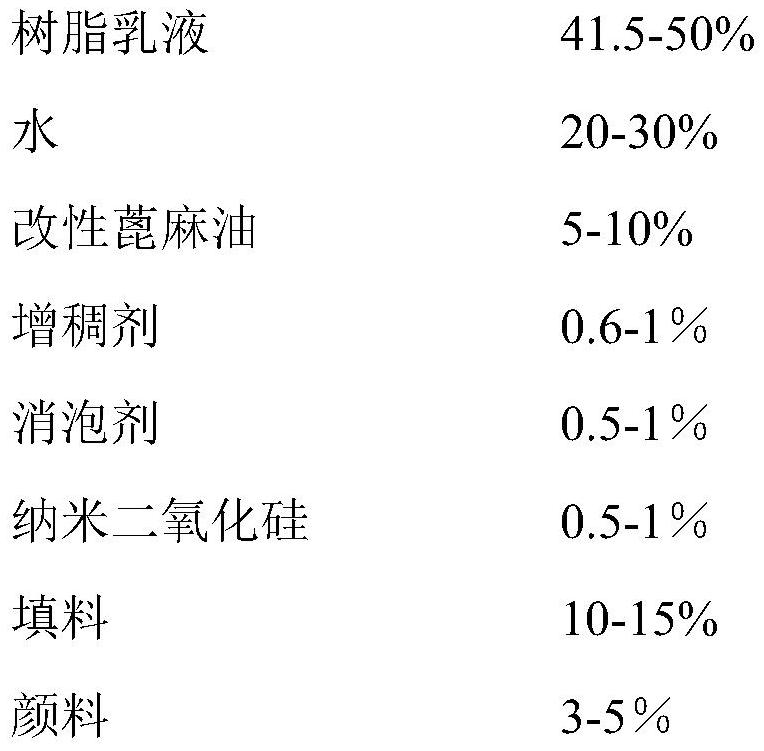

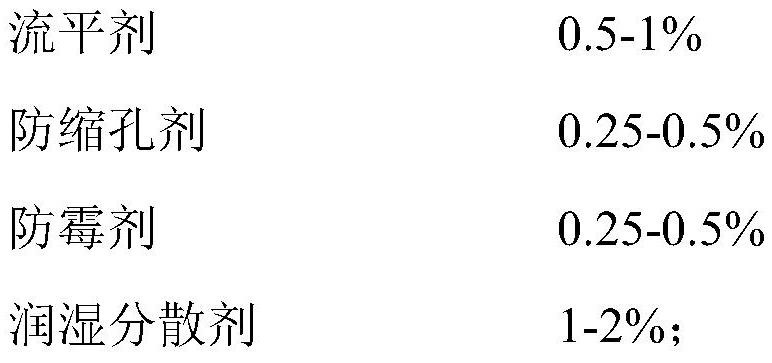

Method used

Image

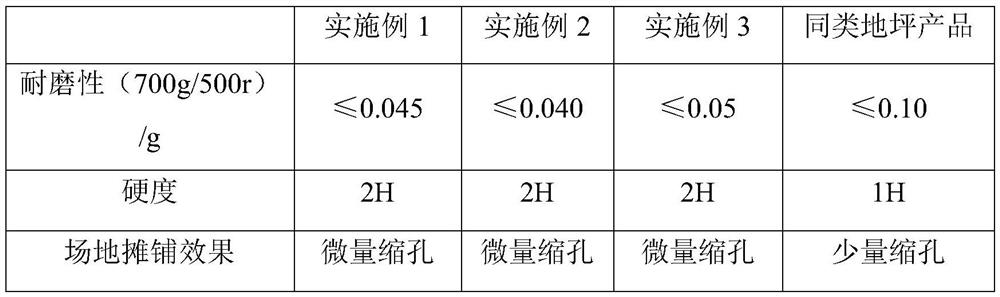

Examples

Embodiment 1

[0033] (1) Put 200g of water and KSR096, 20g into the reaction kettle, add F-047, 2.5g, TEGOWet270, 2.5g, nano-silica 5g, R906, 40g, 3000 mesh kaolin 60g, water-based green slurry 8603 in turn under stirring , 49g and YD701, 5g, stirred at 800 rpm for 20min, then added half of the formula C-140, 3g, stirred at 1200 rpm for 25min, then added FAST538, 500g, PX-BM96, 100g, BYK346, 10g and the remaining C- 140, 3g, stirred at 1500 rpm for 30 minutes, and filled into barrels to obtain component A;

[0034] (2) During construction, mix A component and B component curing agent (S-103, Wuhan Shiquanxing Polyurethane Technology Co., Ltd.) according to the mass ratio of 14:1, and then add A component and B group Divide 30% of the total mass of the curing agent into water and stir evenly, then spread it on the base surface that has been backed.

Embodiment 2

[0036] (1) Put 300g of water and KSR096, 10g into the reaction kettle, add F-047, 5g, TEGO Wet270, 5g, nano-dioxide, 10g, R906, 60g, 90g of 3000 mesh kaolin, water-based green slurry 8603, 30g and YD701, 10g, stir at 1000rpm for 15min, then add half of the formula C-140, 5g, stir at 1500rpm for 20min, then add FAST538, 415g, PX-BM96, 50g, BYK346, 5g and the remaining C-140 , 5g, stirred at 1800 rpm for 20min, and filled into barrels to obtain component A;

[0037] (2) During construction, mix A component and B component curing agent (S-103, Wuhan Shiquanxing Polyurethane Technology Co., Ltd.) according to the mass ratio of 17:1, and then add A component and B group Divide 20% of the total mass of the curing agent into water and stir evenly, then spread it on the base surface that has been backed.

Embodiment 3

[0039] (1) Put 250g of water and KSR096, 15g into the reaction kettle, add F-047, 4g, TEGO Wet270, 4g, nano-silica 7g, R906, 50g, 3000 mesh kaolin, 75g, water-based green slurry in turn under stirring 8603, 50g and YD701, 7g, stirred at 900 rpm for 17min, then added half of the formula C-140, 4g, and stirred at 1350 rpm for 27min, then added FAST538, 454g, PX-BM96, 70g, BYK346, 6g and the remaining C- 140, 4g, stirred at 1650 rpm for 25 minutes, and prepared A component in barrels;

[0040] (2) During construction, mix A component and B component curing agent (S-103, Wuhan Shiquanxing Polyurethane Technology Co., Ltd.) according to the mass ratio of 20:1, and then add A component and B group Divide 10% of the total mass of the curing agent into water and stir evenly, then spread it on the base surface that has been backed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com