Environmentally friendly anti-wear and anti-rust chain grease

An environmentally friendly, grease technology, used in lubricating compositions, petroleum industry, etc., to achieve the effects of safe and environmentally friendly use, strong resistance to salt spray, human health and environmental harmlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

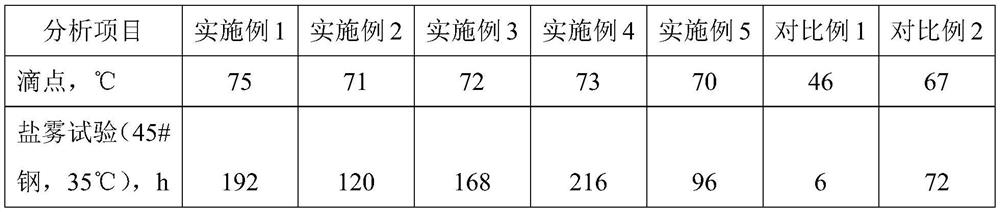

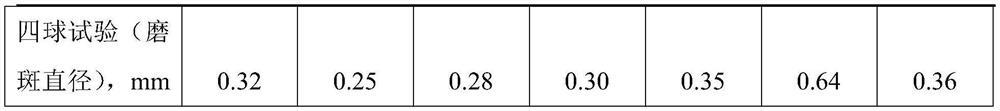

[0033] The proportions of Examples 1-5 are shown in Table 1, wherein the data of Comparative Example 1 and Comparative Example 2 are from CN20121042735, and the performances of Examples 1-5 and Comparative Examples 1-2 are shown in Table 2

[0034] The composition of table 1 embodiment 1-5

[0035]

[0036] Table 2 embodiment 1-5 and comparative example 1-2 performance analysis result

[0037]

[0038]

[0039] From Table 1 and Table 2, it can be seen that the product of the present invention has obvious advantages in high temperature performance (dropping point), anti-salt spray performance and anti-wear performance, and does not contain harmful elements barium and phosphorus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com