Rail type walking unit

A walking unit, track-type technology, applied in the directions of manipulators, supporting machines, mechanical equipment, etc., can solve the problems of easy wear and tear of transmission parts, complex transmission process, and high environmental requirements, avoiding slippage, high transmission accuracy, and long effective life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

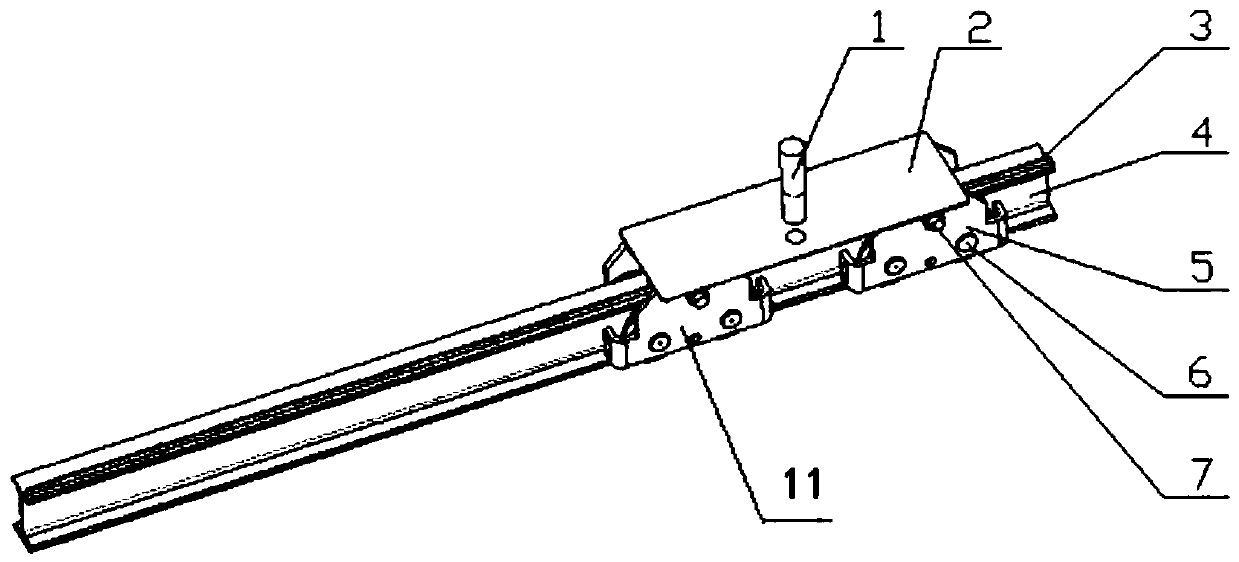

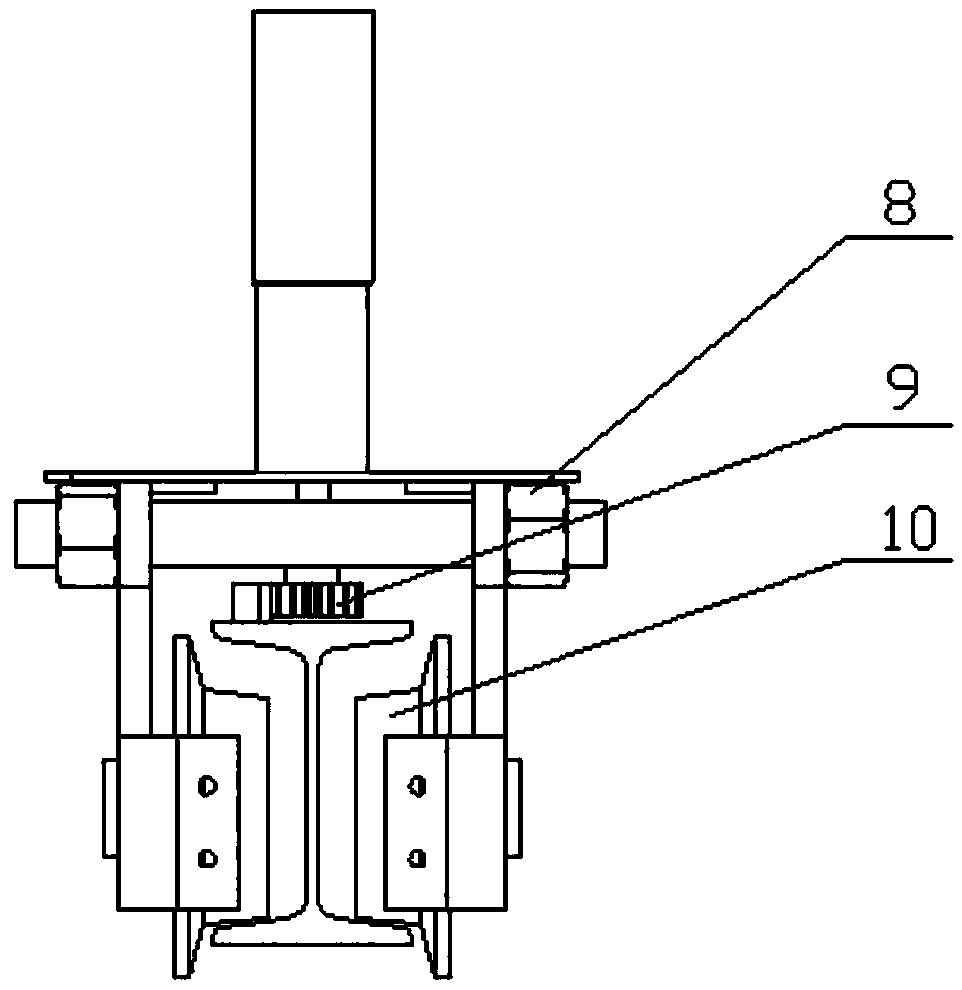

[0020] Such as figure 1 , figure 2 As shown, a track-type walking unit includes a driving part and a guiding part,

[0021] The driving part includes a servo motor 1, a traveling unit platform 2, a gear 9, a rack track 3, and an I-shaped steel track 4. There is a mounting hole, the mounting hole is set at the center of the walking unit platform 2, which can avoid the uneven force of the I-shaped steel rib plate, and the output shaft of the servo motor 1 is vertically installed above the I-shaped steel rail 4 through the mounting hole , the output shaft of the servo motor 1 is connected to the gear 9, and the rack track 3 is fixed on one side of the upper surface of the upper rib plate of the I-shaped steel track 4 in parallel, and the gear 9 meshes with the rack track 3; The servo motor 1 drives the gear 9 to move linearly on the rack track 3; since the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com