Liquid cooling distributed control system and method

A distributed control system and control system technology, applied in lighting and heating equipment, heat exchange equipment, etc., can solve problems such as messy control functions, only point-to-point control, and complex wiring on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

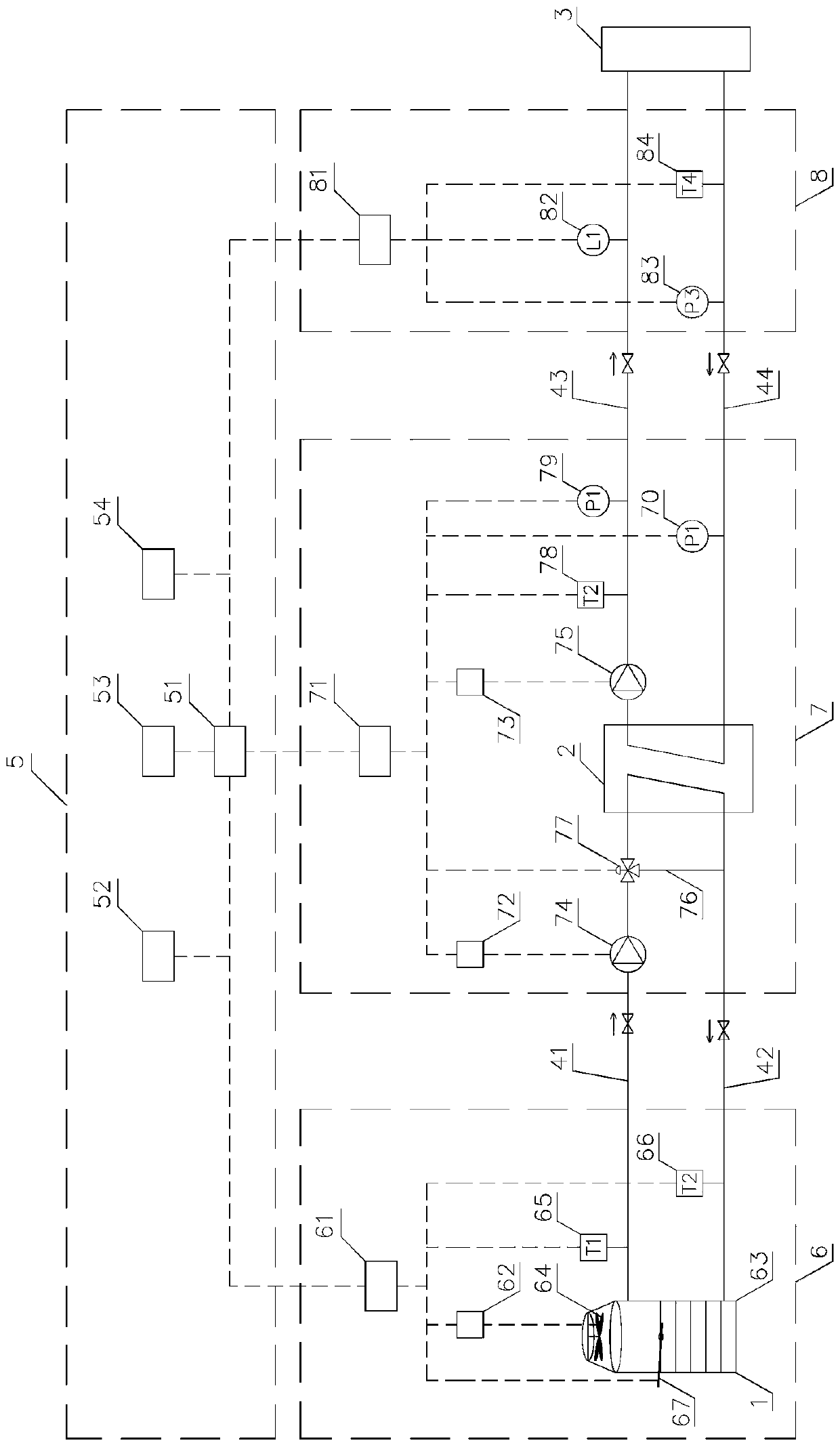

[0054] like figure 1 As shown, a liquid-cooled distributed control system includes a cold source 1, a liquid-liquid heat exchanger 2, and one or more server cabinets 3. The cold source 1 and the liquid-liquid heat exchanger 2 pass through a primary water supply pipe 41 , the primary return pipe 42 is connected, the liquid-liquid heat exchanger 2 is connected with the server cabinet 3 through the secondary water supply pipe 43 and the secondary return pipe 44, and the liquid-cooled distributed control system also includes a centralized monitoring system 5 and a cooling source control system 6 , heat exchange control system 7;

[0055] The centralized monitoring system 5 is electrically connected to the cold source control system 6 and the heat exchange control system 7 respectively, and is used for centralized control of the cold source control system 6 and the heat exchange control system 7;

[0056] The cold source control system 6 is used to control the cooling efficiency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com