High-haze high-light transmittance light diffuser plate and preparation method thereof

A technology of light diffusion plate and high light transmittance, applied in optics, optical components, instruments, etc., can solve problems such as ineffective export, high haze and high light transmittance without clear data display, etc., to reduce production costs, The effect of simple materials and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

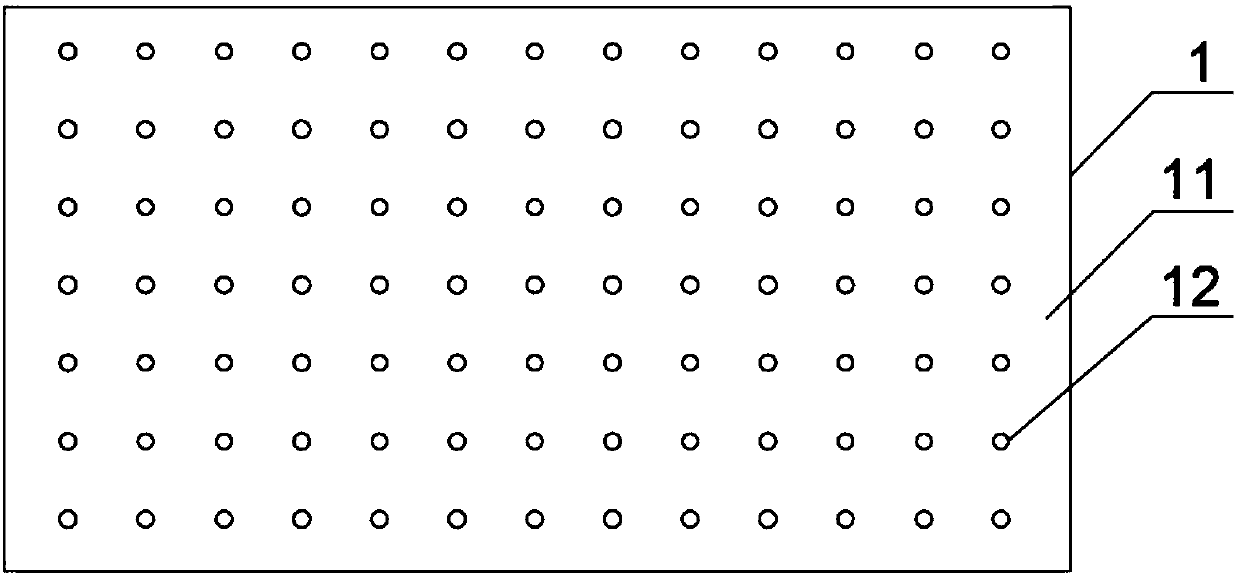

[0037] A light diffusion plate with high haze and high light transmittance is characterized in that it comprises the following components by mass fraction: 96.7% of optical grade polystyrene, and 3.3% of organic silicon. The diffuser had a haze of 99.8% and a light transmittance of 80%.

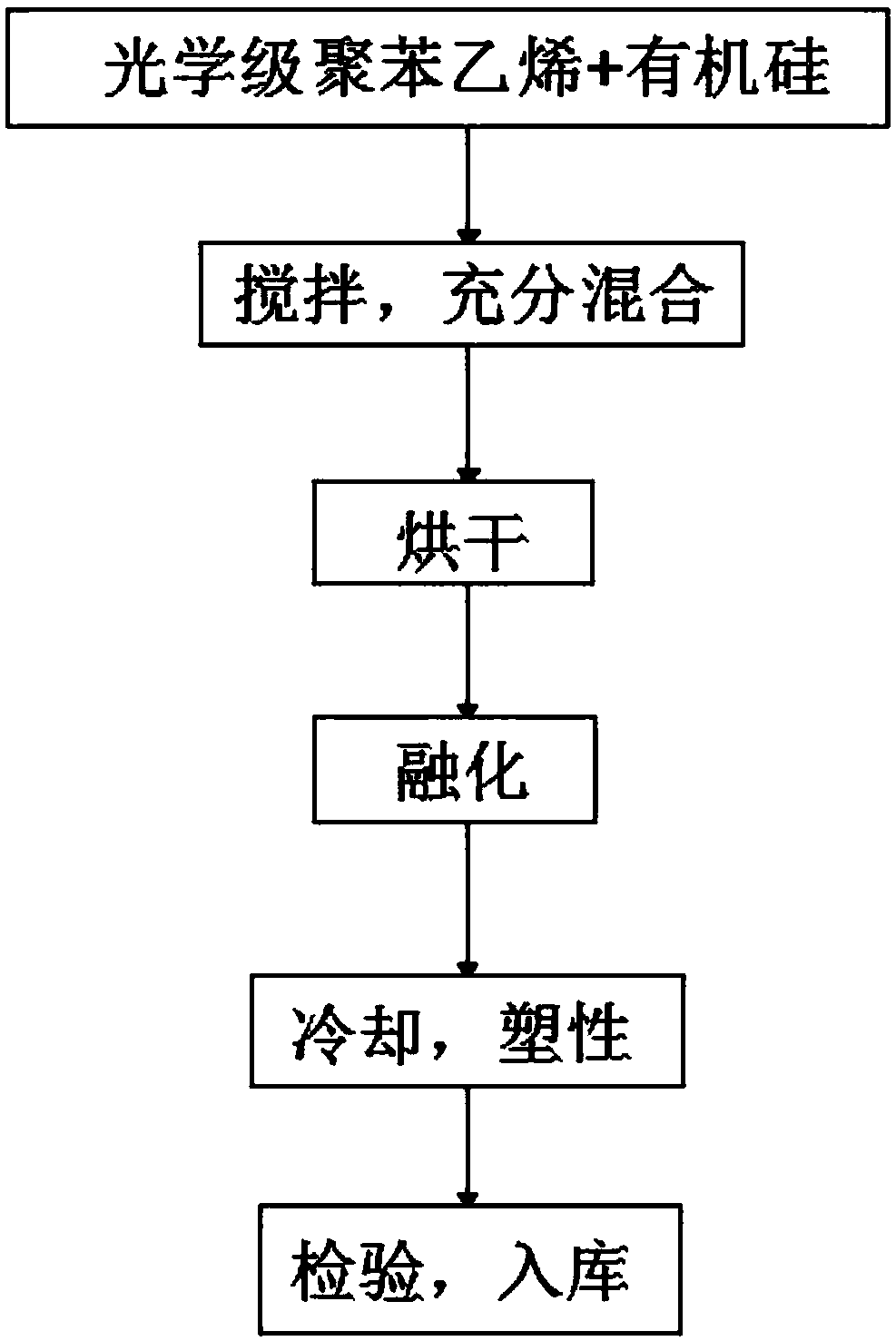

[0038] The preparation method of the light diffusion plate with high haze and high light transmittance as described above comprises the following steps:

[0039] (1) Take the material in proportion and put it into the container;

[0040] (2) Stir the materials in the container evenly to form a mixture;

[0041] (3) The mixture obtained in step (2) is pumped into a drier, and the drying temperature is adjusted to be 71° C., and the drying time is 4 hours;

[0042] (4) Input the drying material obtained in step (3) into the heating pipeline, the temperature of the heating pipeline is 170-250° C., and the method of heating in stages is adopted to melt it into a slurry;

[0043] (5) The slurry...

specific Embodiment example 2

[0046]A light diffusion plate with high haze and high light transmittance is characterized in that it comprises the following composition in mass fraction: 99.2% of optical grade polystyrene and 0.8% of organic silicon. The diffuser had a haze of 99.5% and a light transmittance of 85%.

[0047] The preparation method of the light diffusion plate with high haze and high light transmittance as described above comprises the following steps:

[0048] (2) Take the material in proportion and put it into the container;

[0049] (2) Stir the materials in the container evenly to form a mixture;

[0050] (3) The mixture obtained in step (2) is pumped into a drier, and the drying temperature is adjusted to be 89° C., and the drying time is 2.1 hours;

[0051] (4) Input the drying material obtained in step (3) into the heating pipeline, the temperature of the heating pipeline is 170-250° C., and it is melted into a slurry by adopting a staged heating method;

[0052] (5) The slurry mix...

specific Embodiment example 3

[0055] A light diffusion plate with high haze and high light transmittance is characterized in that it comprises the following components in mass fraction: 97.7% of optical grade polystyrene and 2.3% of organic silicon. The diffuser had a haze of 99.6% and a light transmittance of 82%.

[0056] The preparation method of the light diffusion plate with high haze and high light transmittance as described above comprises the following steps:

[0057] (3) Take the material in proportion and put it into the container;

[0058] (2) Stir the materials in the container evenly to form a mixture;

[0059] (3) The mixture obtained in step (2) is pumped into a drier, and the drying temperature is adjusted to be 80°C, and the drying time is 3 hours;

[0060] (4) Input the drying material obtained in step (3) into the heating pipeline, the temperature of the heating pipeline is 170-250° C., and it is melted into a slurry by adopting a staged heating method;

[0061] (5) The slurry mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com