Wind power plant fault data collecting system and collecting method based on SCADA system

A fault data and acquisition system technology, applied in the direction of electrical digital data processing, data processing applications, special data processing applications, etc., can solve the problems of poor timeliness of fault data collection, reduce labor intensity, high labor intensity, etc., to achieve artificial remote Acquisition, reduction of labor costs, and high timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

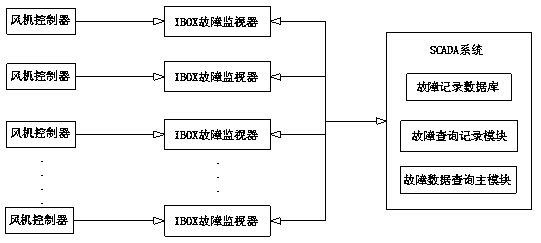

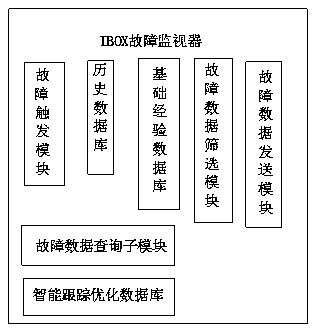

[0041] Such as figure 1 Shown, a kind of wind farm fault data acquisition system based on SCADA system, comprises the fan controller of fan in the SCADA system, IBOX fault monitor and wind farm, described fan controller can generate fault code when fan breaks down; The controller communicates with the IBOX fault monitor, and the IBOX fault monitor communicates with the SCADA system, and is characterized in that: the IBOX fault monitor is configured with a historical database and a basic experience database; the basic experience database stores There is a fault data type mapping table corresponding to various fault codes; the IBOX fault monitor is configured with the following functional modules:

[0042] The fault trigger module is used to judge whether there is abnormal data in the data received by the IBOX fault monitor from the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com