Telephone receiver and assembly method thereof

A receiver and free technology, applied in the field of receivers, can solve the problems of complex structure and poor sensitivity of moving iron receivers, and achieve the effects of reducing vibration response time, improving sensitivity, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

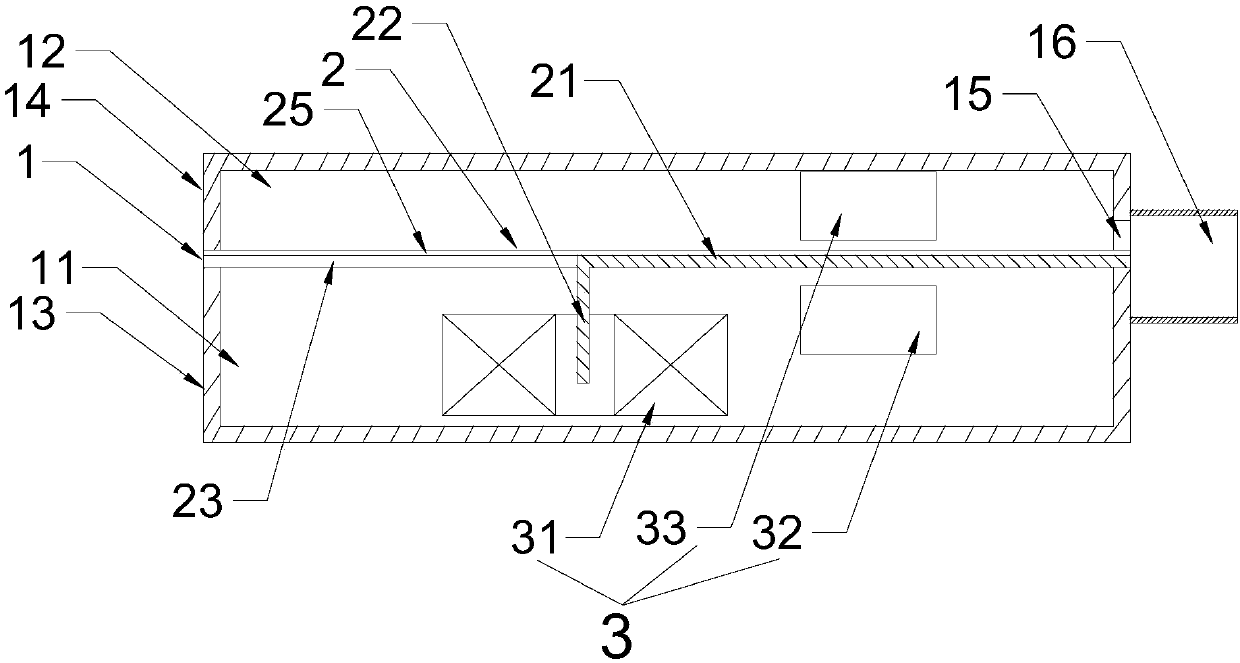

[0065] This embodiment provides a receiver, such as figure 1 As shown, it includes a housing 1 , a diaphragm mechanism 2 and an electromagnetic mechanism 3 .

[0066] The casing 1 includes a first housing 13 surrounded by a first bottom surface and side walls, and a second housing 14 surrounded by a second bottom surface and side walls. The openings of the first housing 13 and the second housing 14 are buckled Together to form a hollow cavity. Both the first housing 13 and the second housing 14 are made of high magnetic permeability alloy, and the side wall of the second housing 14 is provided with a sound hole 15, and the periphery of the sound hole 15 is provided with a sound guide tube 16, The sound guide tube 16 is arranged on the side wall of the housing 1 .

[0067] It should be noted that the installation between the first housing 13 and the second housing 14 is detachable, and the setting position of the sound hole 15 is not limited, and it can also be arranged on th...

Embodiment 2

[0090] This embodiment provides a receiver, which differs from the receiver provided in Embodiment 1 in that the structure of the diaphragm mechanism 2 is different.

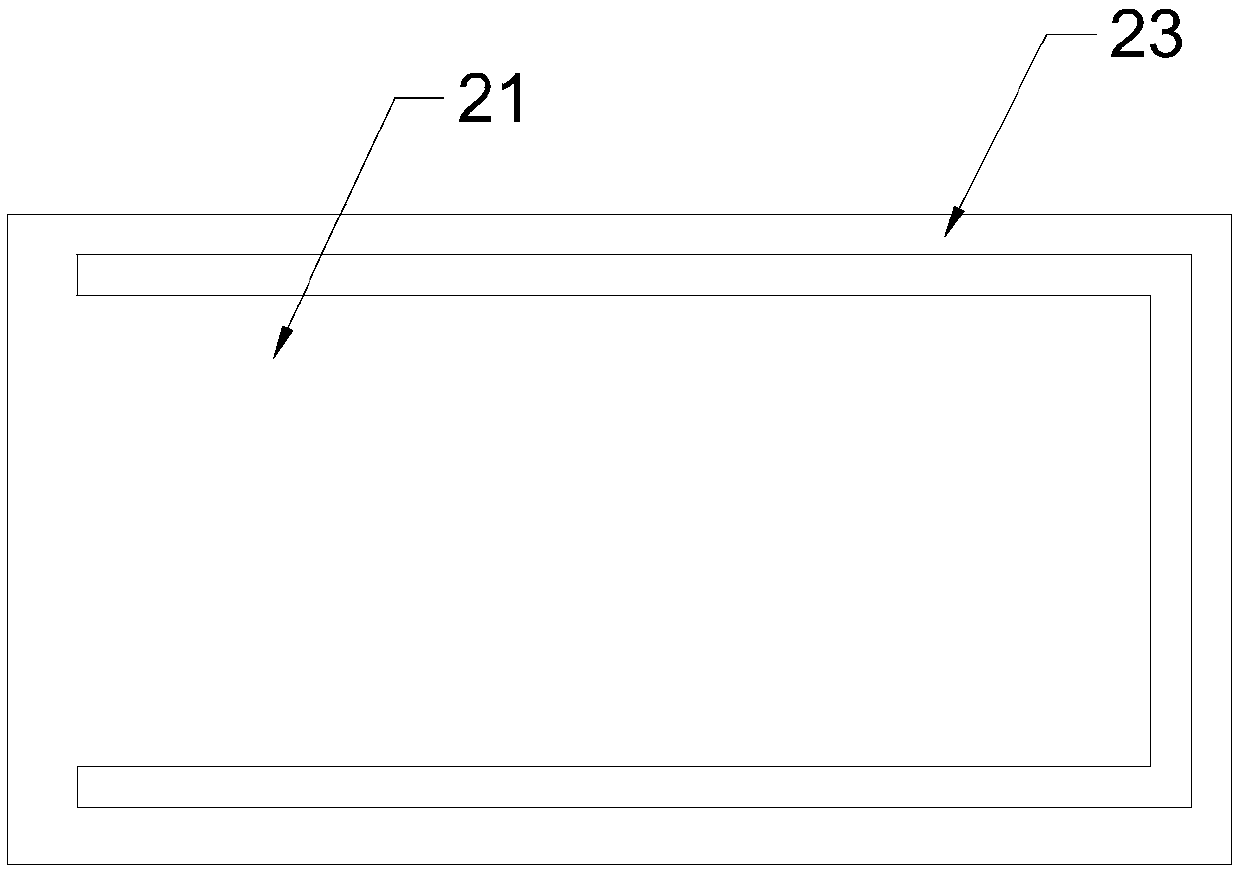

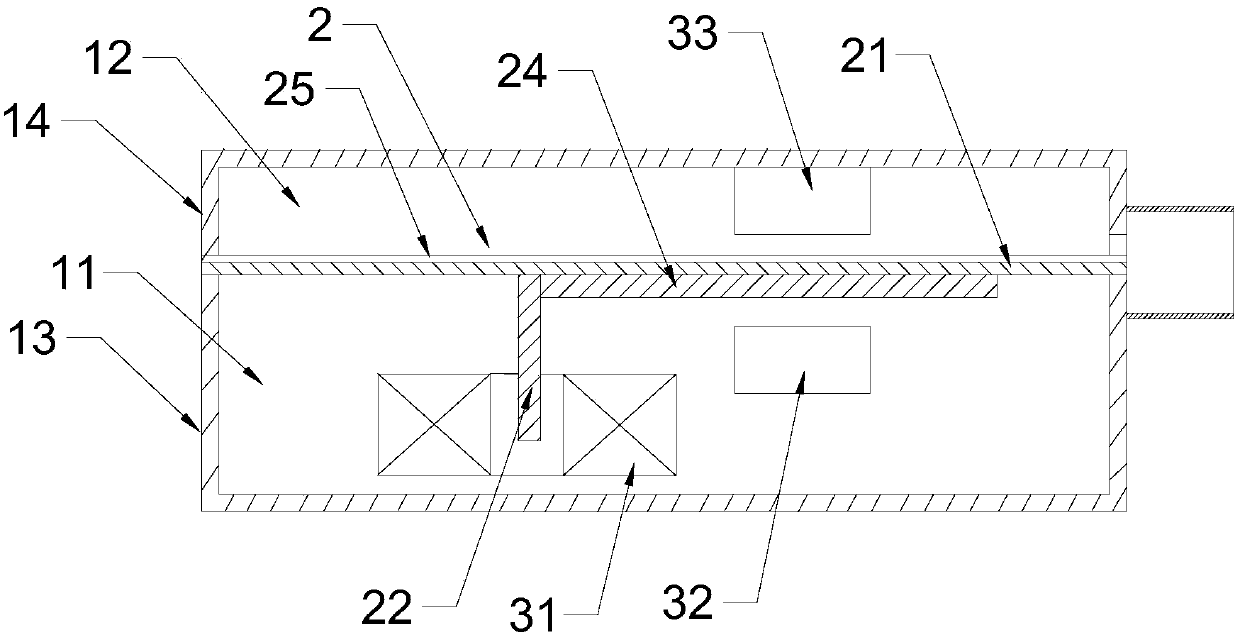

[0091] Such as image 3 As shown, the diaphragm mechanism 2 includes a fixed frame 23, a sounding diaphragm 25 and a vibrating body.

[0092] The structure of the fixing frame 23 is the same as the fixing frame 23 of the receiver provided in Embodiment 1, and will not be repeated here.

[0093] The vibrating body includes a vibrating plate, a free part 22 and a connecting part 24 . Such as figure 2 As shown, the vibrating plate is used as the vibrating part 21 of the vibrating body, which is made of soft magnetic material, one end is fixed on the fixed frame 23 , and the other end is suspended in the inner cavity of the fixed frame 23 . It should be noted that the vibrating plate is not bent, but suspended in the cavity of the fixed frame 23 as a whole.

[0094] The free part 22 and the connecting part 24 a...

Embodiment 3

[0103] This embodiment provides a receiver. Compared with any receiver provided in Embodiment 1 or Embodiment 2, the difference lies in that the fixing positions of the fixing frame 23 are different.

[0104] In this embodiment, the outer edge of the fixing frame 23 in the diaphragm mechanism 2 is fixed on the inner wall surface of the second casing 14 .

[0105] The difference between the assembly method (abbreviated as C assembly method) and A assembly method or B assembly method of receiver in the present embodiment is:

[0106] In step S20, the outer edge of the fixed frame 23 in the diaphragm mechanism 2 is fixed on the inner wall surface of the second housing 14, and the second magnetic generating element 33 is avoided;

[0107] In step S30, the opening of the second housing 14 is buckled at the opening of the first housing 13, and the first magnetic generating member 32 in the first housing 13 is connected to the second magnetic generating member 32 in the second housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com