Anti-couple corrosion electromagnetic shielding sealing press strip

A technology of electromagnetic shielding and sealing bead, which is applied in the directions of magnetic field/electric field shielding, sealed shell, gasket/seal, etc. It can solve the problems of inability to realize the water vapor seal of conductive rubber pads, galvanic corrosion, small size, etc., and achieve electromagnetic shielding effectiveness High, strong corrosion resistance, good hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

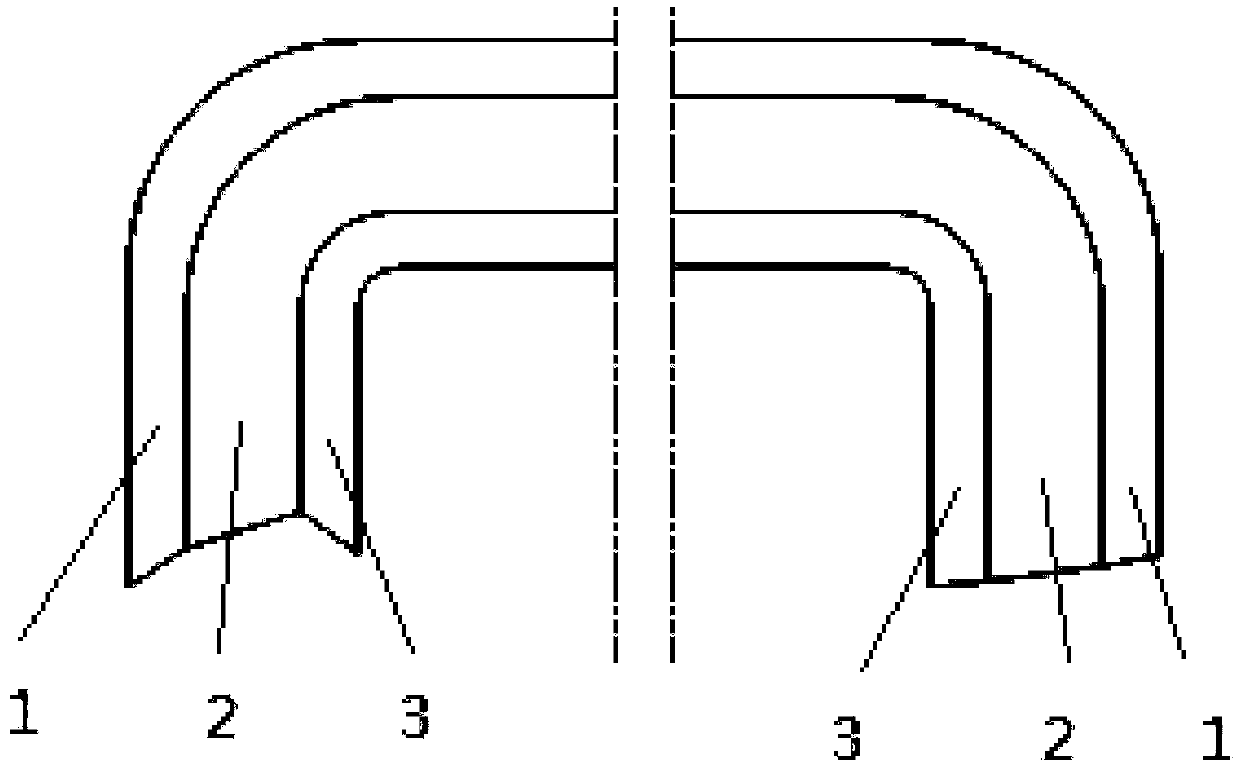

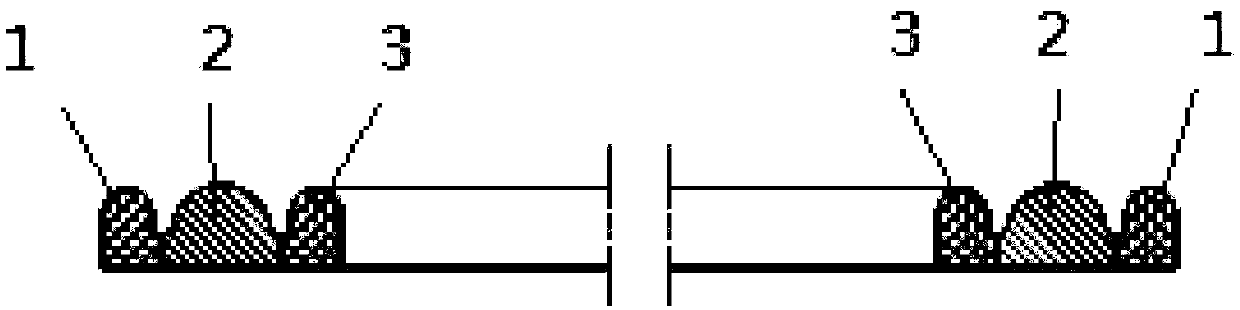

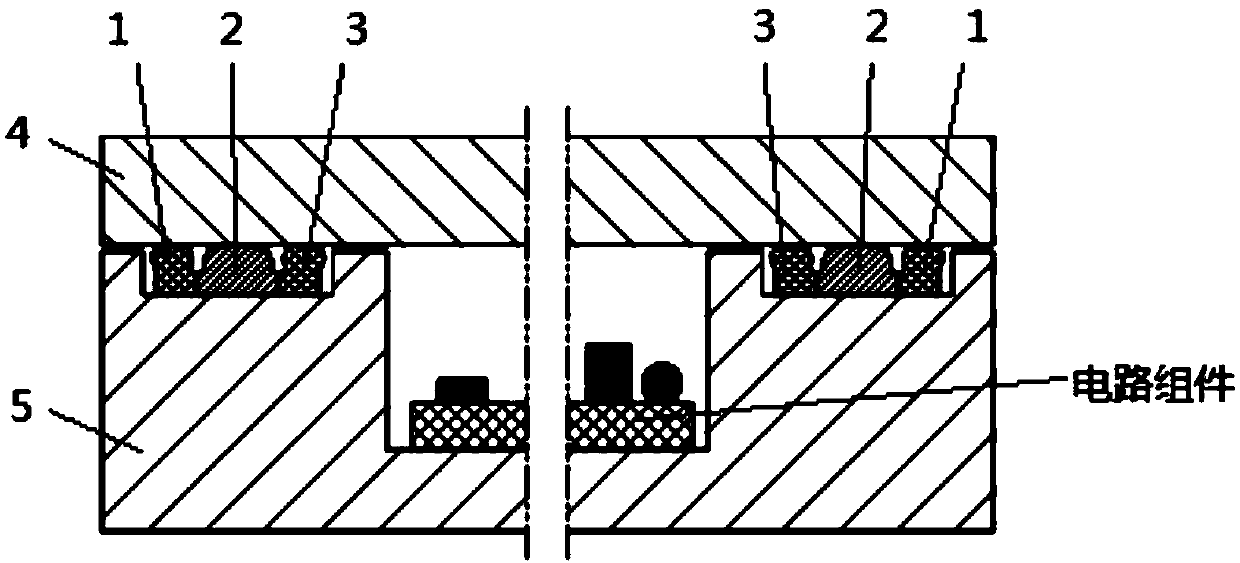

[0024] refer to Figure 1 ~ Figure 2 . In the embodiment described below, an anti-galvanic corrosion electromagnetic shielding sealing gasket is composed of an outer layer insulating rubber strip 1, a middle layer conductive rubber strip 2, and an inner layer insulating rubber strip 3, and it has an outer layer insulating rubber strip 1 →Middle layer conductive rubber strip 2←Inner layer insulating rubber strip 3 sandwich structure, wherein the middle layer conductive rubber strip 2 is sandwiched between the groove formed by the outer layer insulating rubber strip 1 and the inner layer insulating rubber strip 3 in the form of a convex circle , the middle conductive rubber strip 2 realizes the electromagnetic shielding of the chassis and cabinet electronic equipment in contact with the metal substrate, the outer insulating rubber strip 1, the inner insulating rubber strip 3 and the convex round strip of the middle conductive rubber strip 2 and the elastic extrusion groove forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com