Adaptive vibration-reducing and noise-reducing foam sandwich plate and preparation method thereof

A vibration and noise reduction, adaptive technology, applied in aerospace, ships and high-speed rail fields, can solve the problems of increasing mass, difficult vibration and noise reduction, influence, etc., to achieve strong stiffness and strength, strong resistance to deformation and resistance. The effect of destructive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure, principle and preparation method of the invention will be further described below in conjunction with the accompanying drawings.

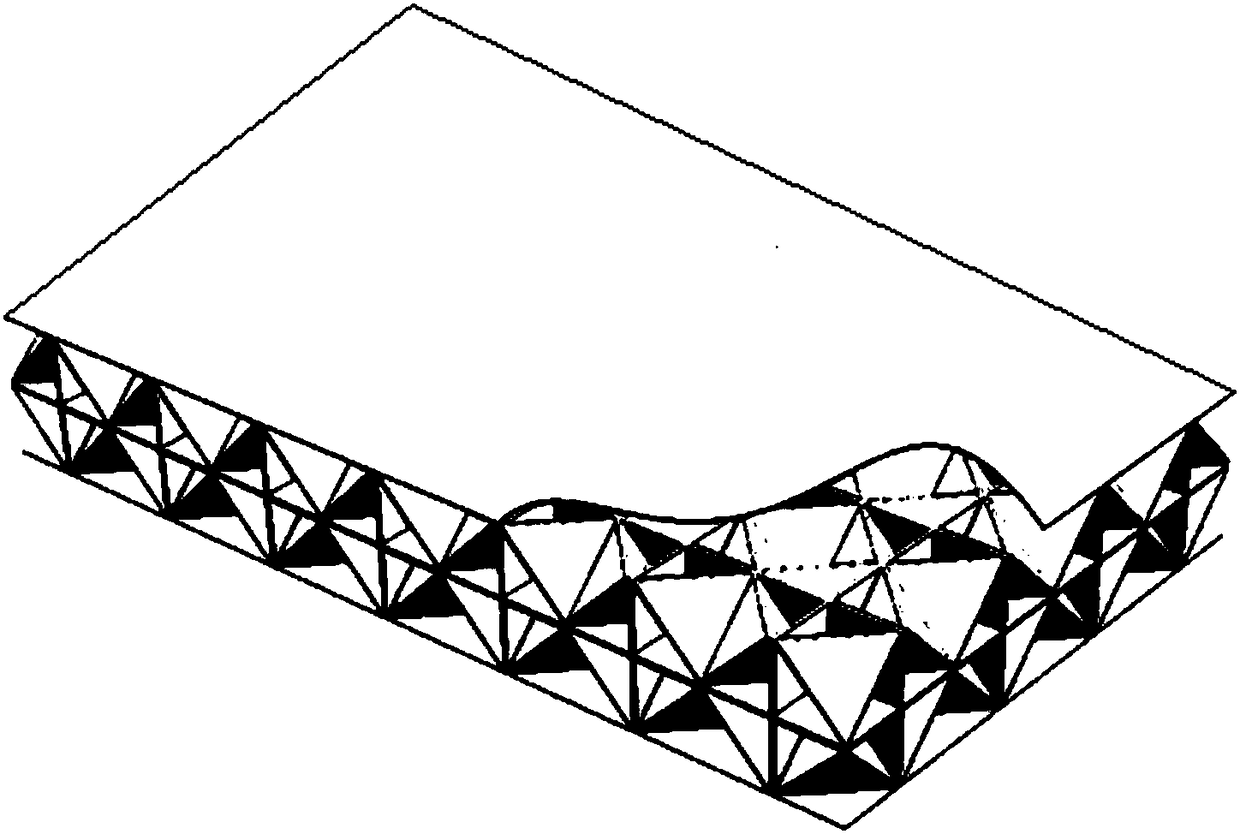

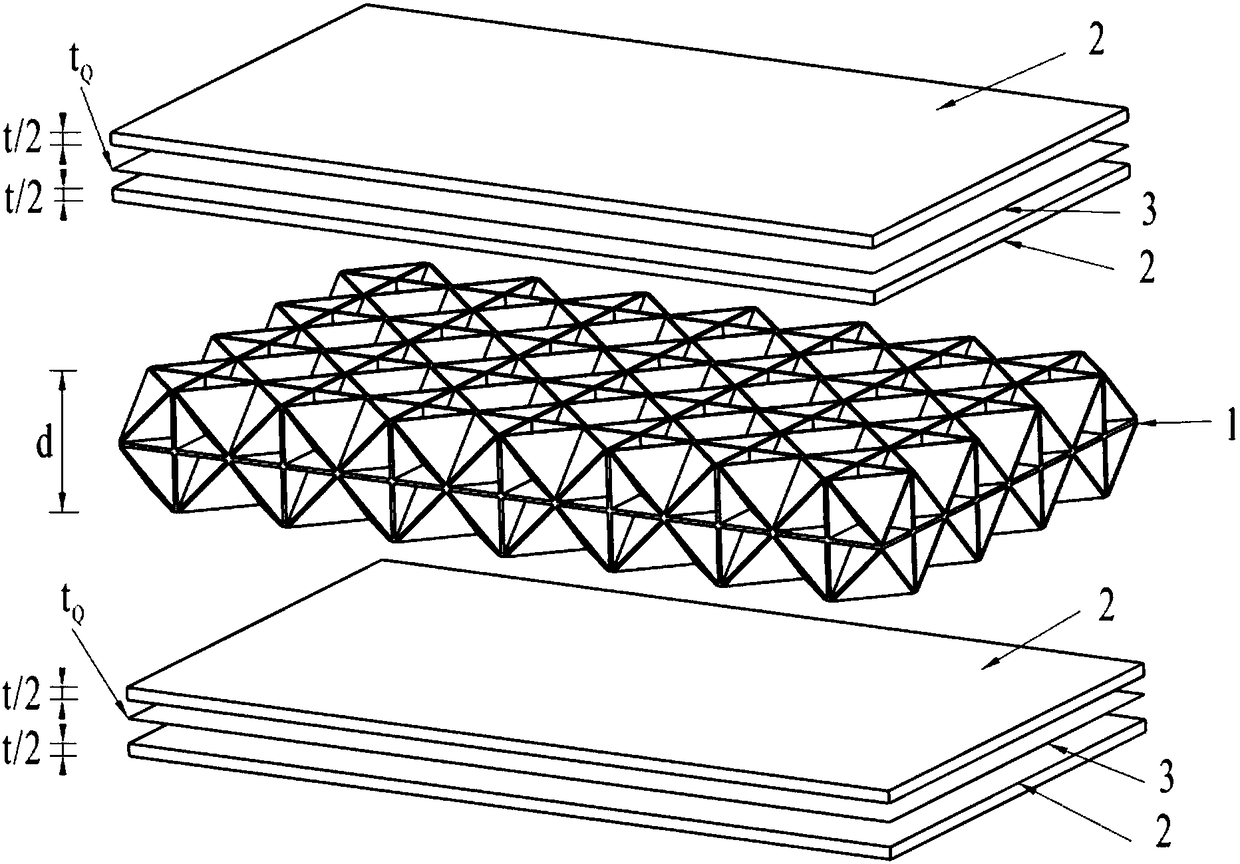

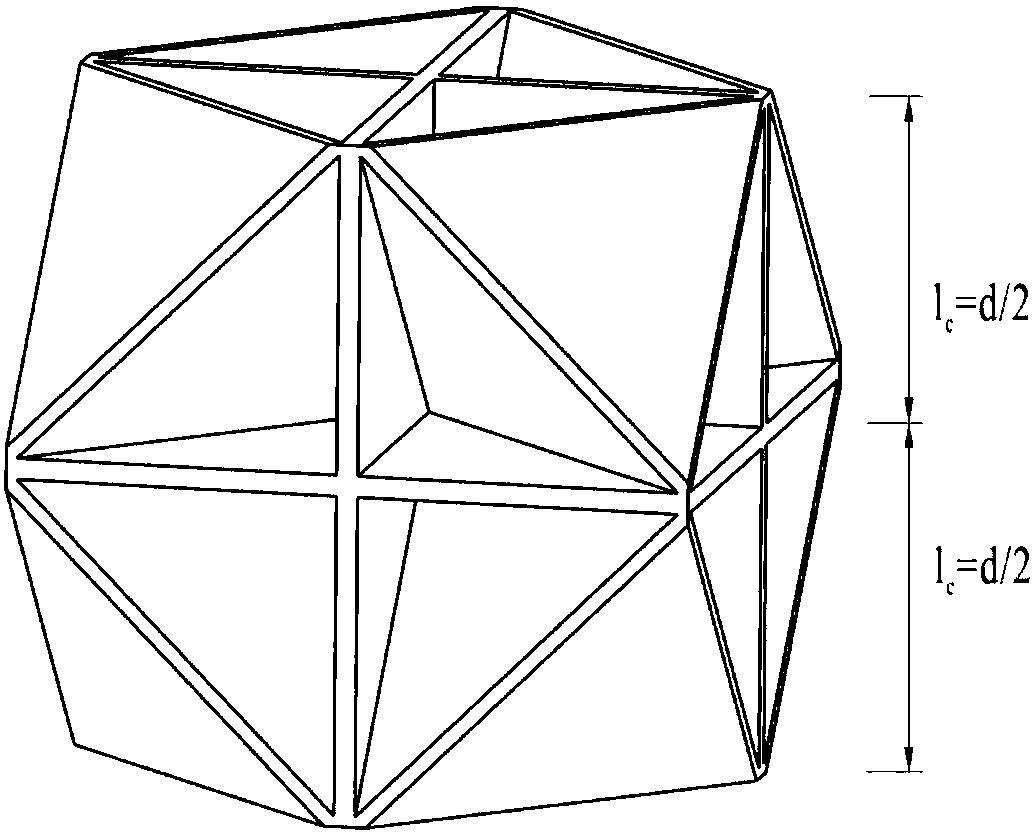

[0019] figure 1 It is a schematic diagram of the overall structure of the ultra-light and high-strength self-adaptive vibration-reduction and noise-reduction foam sandwich panel proposed by the present invention, which includes a metamaterial ISOMAX foam sandwich core 1 and Qtech413 constrained damping upper and lower panels (see figure 2 ). The metal ISOMAX foam sandwich structure and constrained damping upper and lower panel structures in the figure are just examples, and the specific structural dimensions and the number of ISOMAX foam units (see image 3 ), the metal material used in the sandwich, the thickness of the metal sheet 2 used in the upper and lower panels and the thickness of the Qtech413 coating film 3 can be properly selected according to actual engineering needs. Among them, ISOMAX is the name of the sandwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com