Purified water production device and production method

A technology for production equipment and purified water, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of unstable water quality and high operating cost of purified water production equipment, and achieve the effect of water production Good, save water, good water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

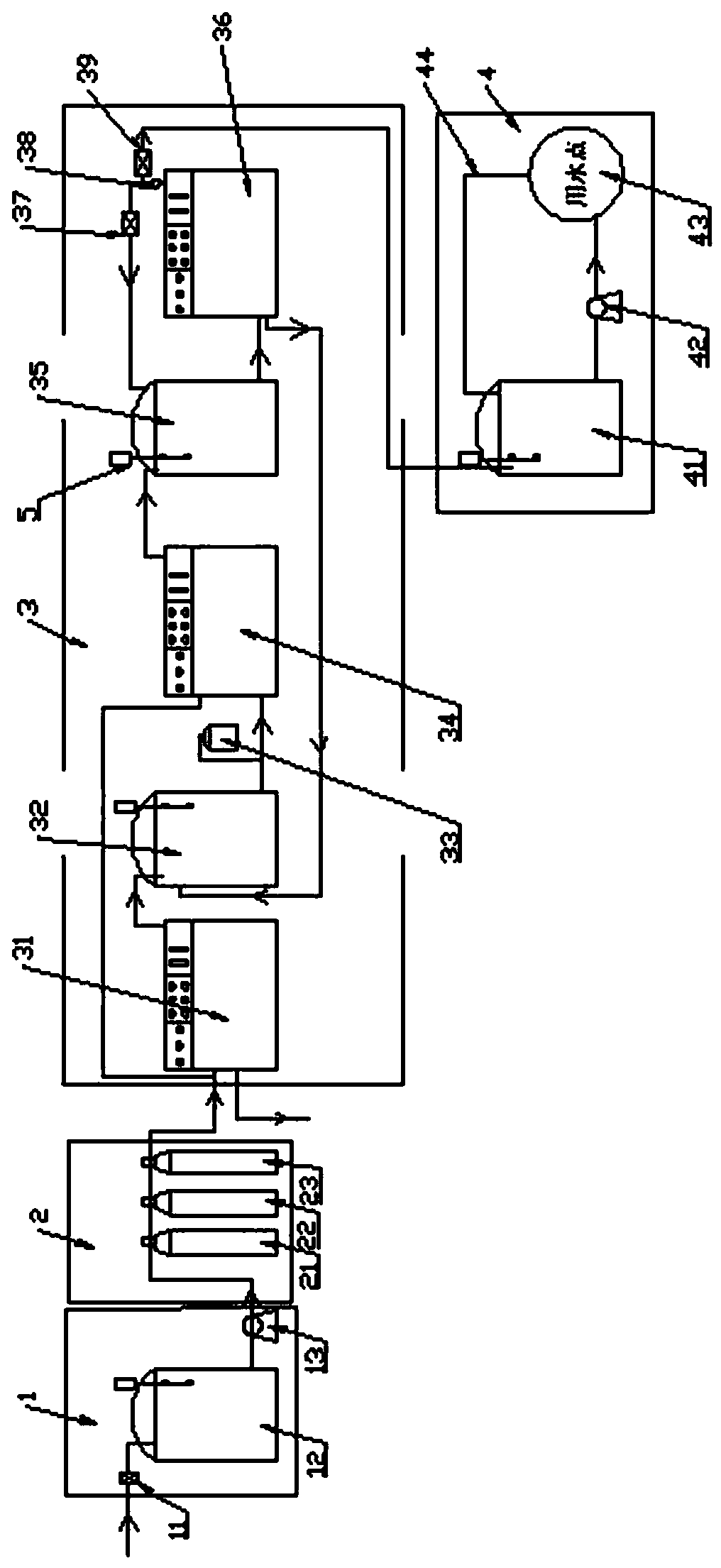

[0032] A kind of purified water production equipment, see figure 1 , including raw water buffer device 1, filter device 2, multi-stage reverse osmosis component 3 and terminal water device 4 in sequence along the product processing sequence, multi-stage reverse osmosis component 3 includes a primary reverse osmosis component 31, a primary water production tank 32, a secondary Level reverse osmosis component 34, secondary water production tank 35, EDI purified water component 36, the water inlet circuit that flows out after connecting above-mentioned reverse osmosis component to EDI purified water successively; The primary return water circuit of the EDI purified water part 36 is connected with the secondary return water circuit leading to the primary water production tank 32, and the EDI purified water part 36 is connected with the EDI return water circuit leading to the secondary production water tank 35; the terminal water The device 4 includes an EDI water production tank 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com