Preparation method of red-light-emitting glass

A technology that emits red light and glass, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of irregular particle shape and uneven particle size of phosphor powder, and achieve excellent thermal and chemical stability, color Pure, color stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) First, 13mol% of Tb will be 2 o 3 , 24mol% B 2 o 3 , 16mol% Ga 2 o 3 , 6.5mol% Eu 2 o 3 , 3mol% Y 2 o 3 , 15mol% GeO 2 , 22mol% SiO 2 , 0.2mol% SnO 2 , 0.3mol% ZnO 2 Mix until the uniformity is greater than 98% to form a batch;

[0023] 2) Then, add the batch material into the platinum crucible that has been heated to 1450°C; keep warm for 30 minutes;

[0024] 3) Then, cool down the furnace temperature to 1380°C for 30 minutes and keep it warm for 30 minutes;

[0025] 4) Finally, pour the molten glass into a graphite mold at 250°C, put it into a furnace at 710°C after setting the shape, keep it warm for 3 hours, and then cool it down to room temperature at a cooling rate of 1°C / min to obtain a transparent and red light glass.

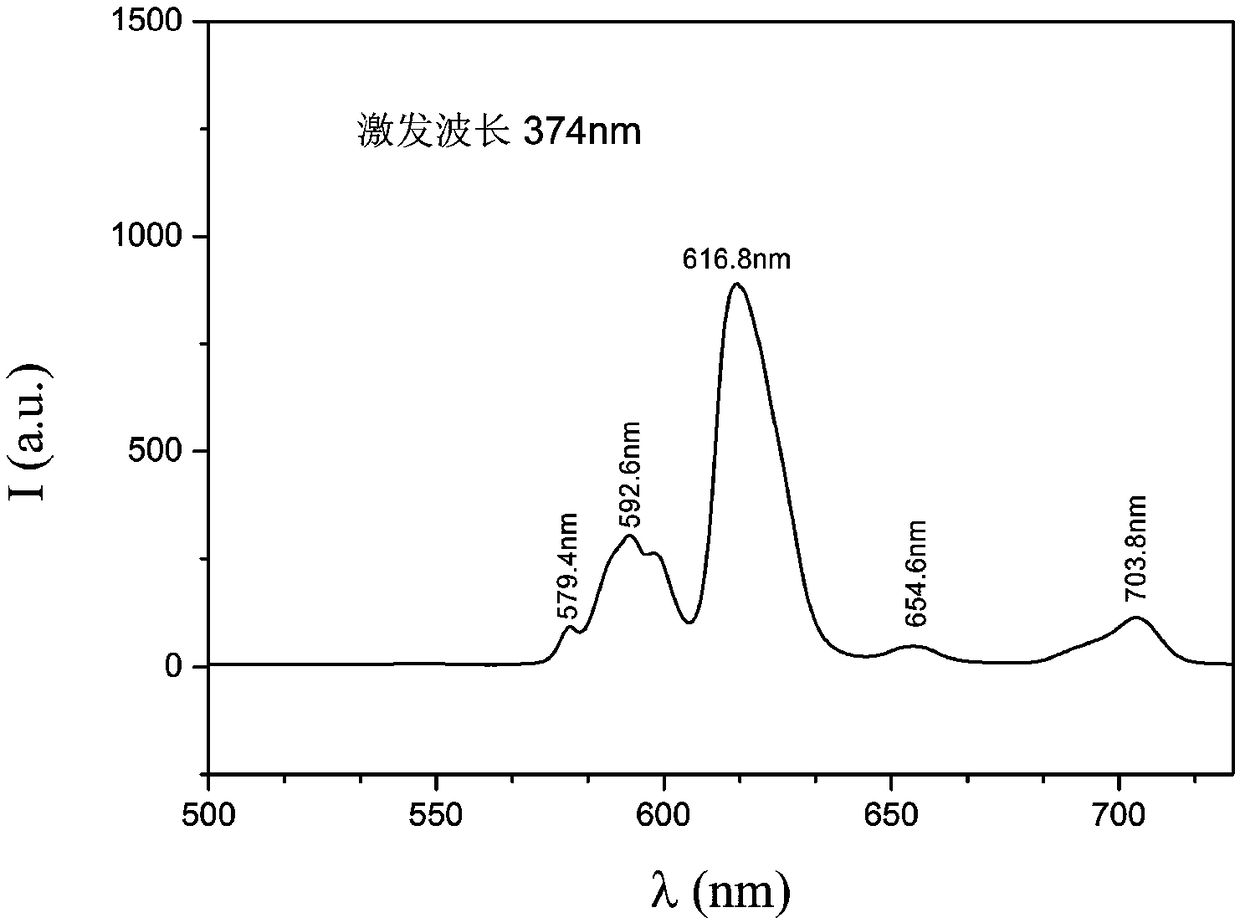

[0026] attached figure 1 is the photoluminescence spectrum of the prepared colorless transparent red-emitting glass at an excitation wavelength of 374nm, wherein the abscissa is the wavelength of the emitted light, and the ordi...

Embodiment 2

[0029] 1) First, 13.2mol% of Tb will be 2 o 3 , 26mol% B 2 o 3 , 14mol% Ga 2 o 3 , 3mol% Eu 2 o 3 , 5mol% Y 2 o 3 , 17mol% GeO 2 , 20mol% SiO 2 , 0.2mol% Sb 2 o 3 , 1mol% SnO 2 , 0.6mol% ZnO 2 Mix until the uniformity is greater than 98% to form a batch;

[0030] 2) Then, add the batch material into the platinum crucible that has been heated to 1460°C; keep warm for 30 minutes;

[0031] 3) Then, cool down the furnace temperature to 1380°C for 30 minutes and keep it warm for 30 minutes;

[0032] 4) Finally, pour the molten glass into a graphite mold at 315°C, put it into a furnace at 710°C after setting the shape, keep it warm for 3 hours, and cool it down to room temperature at a cooling rate of 1°C / min to obtain a transparent and red light glass.

Embodiment 3

[0034] 1) First, 15mol% of Tb will be 2 o 3 , 22.1mol% B 2 o 3 , 12mol% Ga 2 o 3 , 5mol% Eu 2 o 3 , 7mol% Y 2 o 3 , 13mol% GeO 2 , 24mol% SiO 2 , 0.6mol% Sb 2 o 3 , 0.3mol% SnO 2 , 1mol% ZnO 2 Mix until the uniformity is greater than 98% to form a batch;

[0035] 2) Then, add the batch material into the platinum crucible which has been heated to 1475°C; keep warm for 30 minutes;

[0036] 3) Then, cool down the furnace temperature to 1380°C for 30 minutes and keep it warm for 30 minutes;

[0037] 4) Finally, pour the molten glass into a graphite mold at 350°C, put it into a furnace at 710°C after setting the shape, keep it warm for 3 hours, and then cool it down to room temperature at a cooling rate of 1°C / min to obtain a transparent and red light glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com