Liquid silicone rubber for middle-high voltage cold-shrinkable cable accessory dry terminal and preparation method of liquid silicone rubber

A technology of liquid silicone rubber and cable accessories, applied in electrical components, circuits, insulators, etc., to achieve the effects of excellent injection molding, excellent insulation and production inertness, and strong insulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

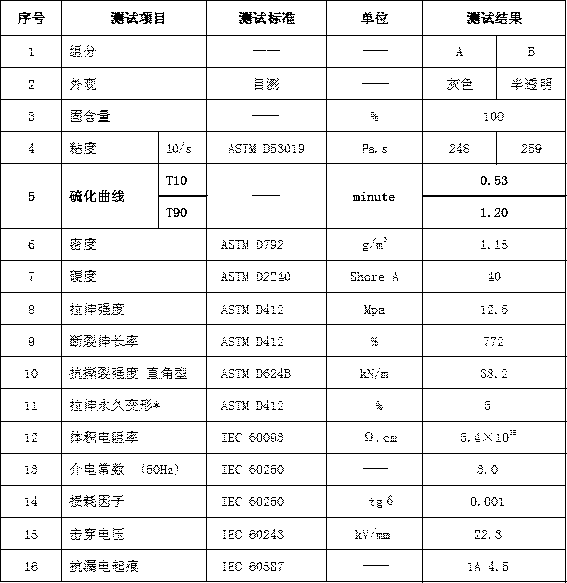

Image

Examples

Embodiment 1

[0012] Example 1: A liquid silicone rubber for dry-type terminals of medium and high-voltage cold-shrinkable cable accessories, which is mainly composed of the following raw materials in parts by weight: 60 parts of vinyl-blocked hexamethyldisilazane, 20 parts of fumed silica Parts, 5 parts of hexamethyldisilazane, 10 parts of nano-sized aluminum hydroxide, 0.1 parts of carbon black, platinum-1,3-divinyl-1,1,3,3-tetramethyldisiloxane 1 part, 1 part of low hydrogen silicone oil and 5 parts of silane coupling agent.

[0013] The preparation method of the liquid silicone rubber of the present invention specifically includes the following steps: (1) making base rubber: 60 parts of vinyl-terminated hexamethyldisilazane, 20 parts of fumed white carbon black, 10 parts of nano-sized aluminum hydroxide, Add 5 parts of silane coupling agent and 5 parts of hexamethyldisilazane in several times, and stir thoroughly after each addition; finally raise the temperature to 200°C, vacuumize, pa...

Embodiment 2

[0014] Example 2: A liquid silicone rubber for dry-type terminals of medium and high-voltage cold-shrinkable cable accessories, which is mainly composed of the following raw materials in parts by weight: 75 parts of vinyl-blocked hexamethyldisilazane, 30 parts of fumed silica 10 parts of hexamethyldisilazane, 15 parts of nano aluminum hydroxide, 0.2 parts of carbon black, platinum-1,3-divinyl-1,1,3,3-tetramethyldisiloxane 1.5 parts, 1.5 parts of low hydrogen silicone oil and 8 parts of silane coupling agent. The preparation method is the same as in Example 1.

Embodiment 3

[0015] Example 3: A liquid silicone rubber for dry-type terminals of medium and high-voltage cold-shrinkable cable accessories, which is mainly composed of the following raw materials in parts by weight: 85 parts of vinyl-terminated hexamethyldisilazane, 40 parts of fumed silica 15 parts of hexamethyldisilazane, 20 parts of nano aluminum hydroxide, 0.3 parts of carbon black, platinum-1,3-divinyl-1,1,3,3-tetramethyldisiloxane 2 parts, 2 parts of low hydrogen silicone oil and 10 parts of silane coupling agent. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com