Dry type reactor epoxy resin insulating medium crack testing method

A dry-type reactor, epoxy resin technology, applied in the direction of testing dielectric strength, etc., can solve the problems of insulation breakdown, insulation cracking of dry-type reactor insulation materials, affecting the safe and reliable operation of the power system, and achieve strong reliability. , High test efficiency, the effect of avoiding breakdown accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

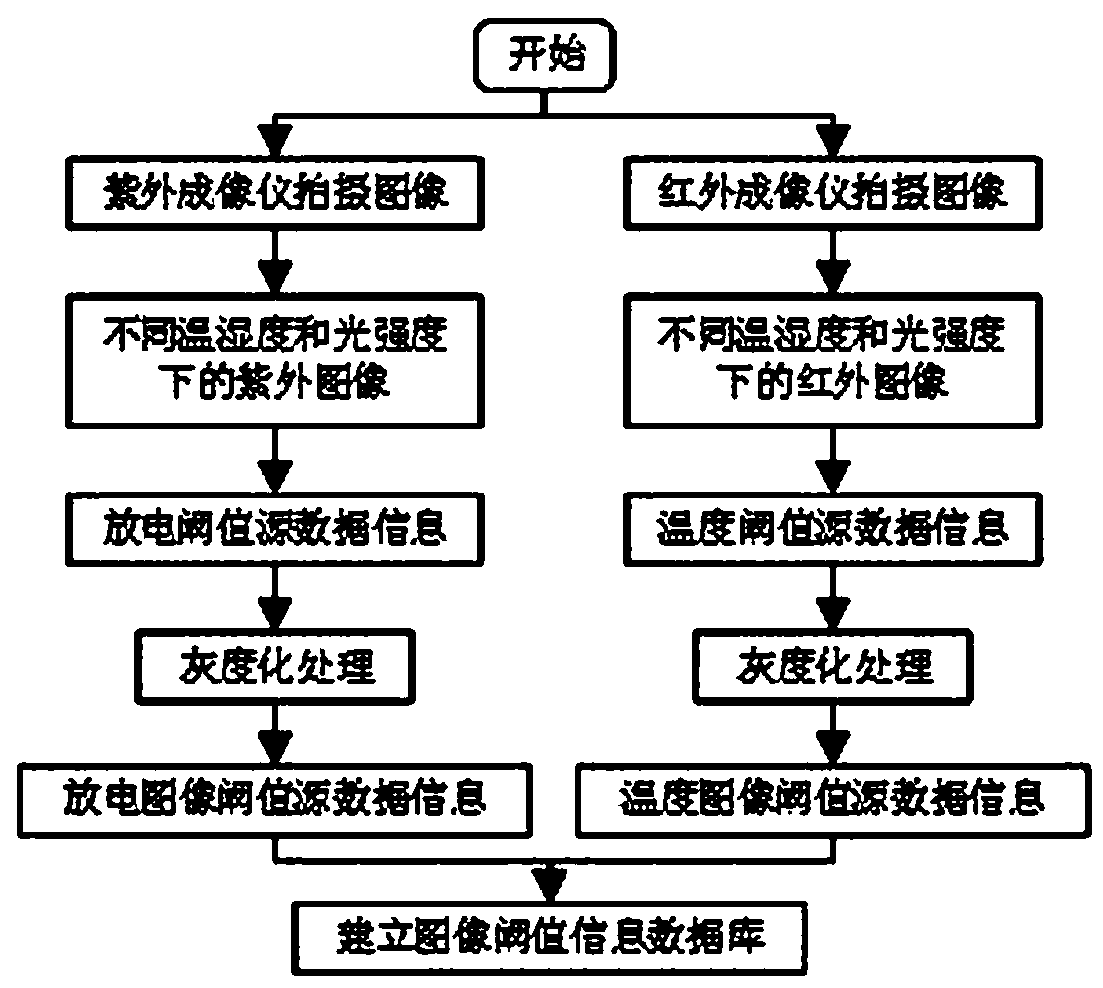

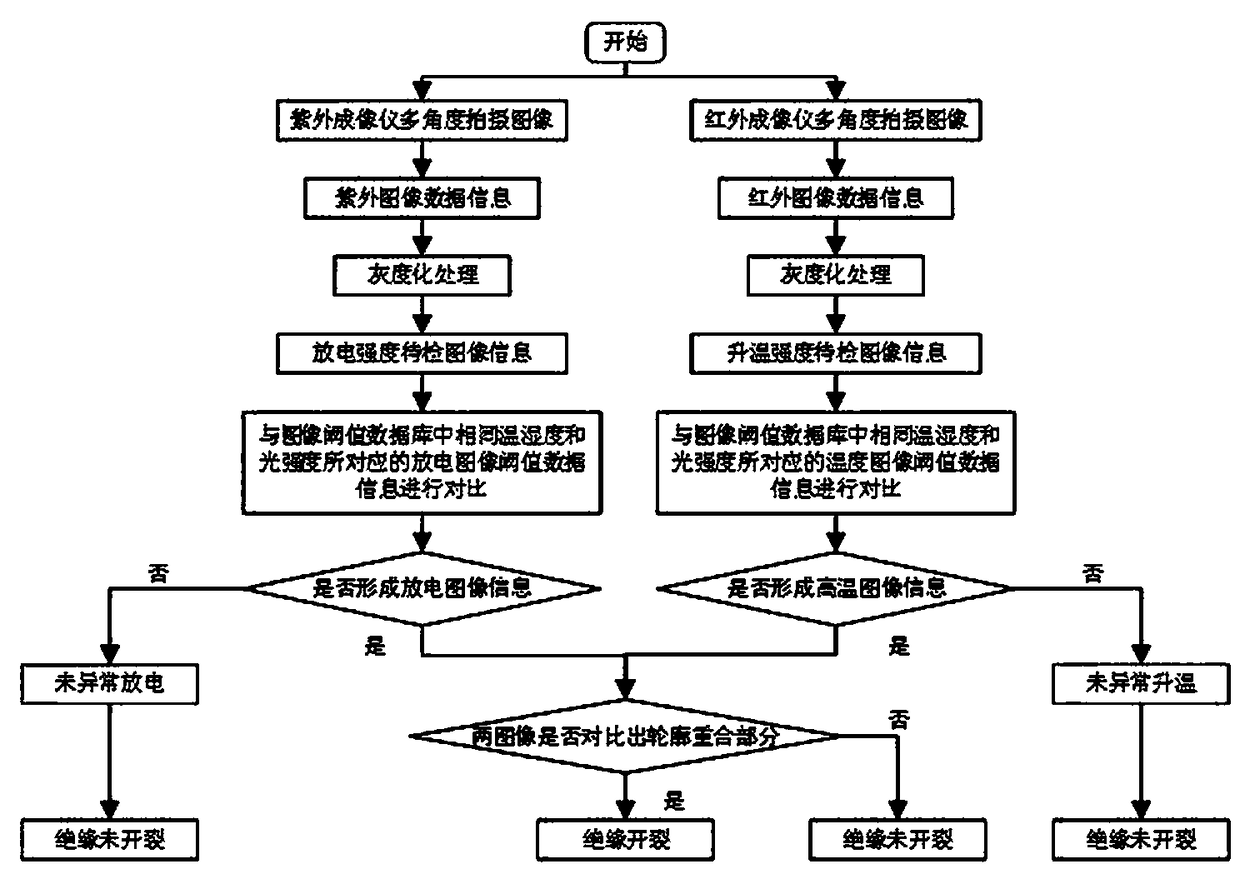

[0040] A dry-type reactor epoxy resin insulation medium crack detection method, the method is an online detection method, which includes the establishment of an image threshold information database and dry-type reactor epoxy resin insulation medium crack detection two steps:

[0041] a. Establish an image threshold information database, the image threshold information database includes discharge image threshold data information and temperature image threshold data information, and the method for obtaining the discharge image threshold data information and temperature image threshold data information includes the following steps:

[0042] a) Collecting images of the cracked epoxy resin insulation medium under different temperature, humidity and light intensities by means of an ultraviolet imager and an infrared imager, respectively, to obtain ultraviolet images and infrared images under different temperature, humidity and light intensities;

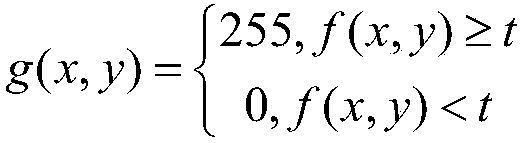

[0043]b) Extract the pixels of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com