Cation exchange membrane and preparation method thereof

A technology of cation exchange membrane and membrane liquid, applied in the field of cation exchange membrane and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

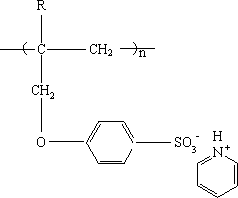

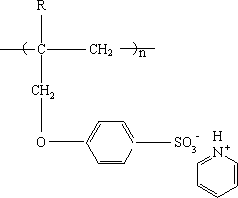

Image

Examples

Embodiment 1

[0026] (1) Synthesis of intermediates:

[0027] Add 15.12g (0.28mol) sodium methoxide to a dry four-necked flask, and add 88ml methanol to dissolve it completely; put 54.88g (0.28mol) sodium p-hydroxybenzenesulfonate dissolved in 400ml methanol into the dropping funnel 1 solution, the dropping funnel 2 was filled with 38.72g (0.32mol) 3-bromopropene; at room temperature, the liquid in the two dropping funnels was slowly added dropwise to the methanol solution of sodium methoxide. ℃, reflux reaction for 4 hours; after the solution is cooled, filter to remove insoluble matter and impurities, distill methanol under reduced pressure, add a small amount of water to the flask to dissolve the solid, cool to 0°C, recrystallize and dry to obtain a white solid powder.

[0028] (2) Monomer synthesis:

[0029] Weigh 15.81g (0.067mol) of the above white solid powder and 7.4g of N-methylpyrrolidone into a dry four-neck flask, stir, add 8.7g (0.075mol) of pyridine hydrochloride, heat up to ...

Embodiment 2

[0038] (1) Synthesis of intermediates:

[0039] Add 15.12g (0.28mol) sodium methoxide to a dry four-necked flask, and add 88ml methanol to dissolve it completely; put 54.88g (0.28mol) sodium p-hydroxybenzenesulfonate dissolved in 400ml methanol into the dropping funnel 1 solution, the dropping funnel 2 was filled with 38.72g (0.32mol) 3-bromopropene; at room temperature, the liquid in the two dropping funnels was slowly added dropwise to the methanol solution of sodium methoxide. ℃, reflux reaction for 4 hours; after the solution is cooled, filter to remove insoluble matter and impurities, distill methanol under reduced pressure, add a small amount of water to the flask to dissolve the solid, cool to 0°C, recrystallize and dry to obtain a white solid powder.

[0040] (2) Monomer synthesis:

[0041] Weigh 14.16g (0.06mol) of the above white solid powder and 11g of N-methylpyrrolidone into a dry four-neck flask, stir, add 7.8g (0.068mol) of pyridine hydrochloride, raise the tem...

Embodiment 3

[0050] (1) Synthesis of intermediates:

[0051] Add 15.12g (0.28mol) sodium methoxide to a dry four-necked flask, and add 88ml methanol to dissolve it completely; put 54.88g (0.28mol) sodium p-hydroxybenzenesulfonate dissolved in 400ml methanol into the dropping funnel 1 solution, the dropping funnel 2 was filled with 33.88g (0.28mol) 3-bromopropene; at room temperature, the liquid in the two dropping funnels was slowly added dropwise to the methanol solution of sodium methoxide. ℃, reflux for 3 hours; after the solution is cooled, remove insoluble matter and impurities by filtration, distill methanol under reduced pressure, add a small amount of water to the flask to dissolve the solid, cool to 0°C, recrystallize and dry to obtain a white solid powder.

[0052] (2) Monomer synthesis:

[0053] Weigh 15.81g (0.067mol) of the above white solid powder and 7.4g of N-methylpyrrolidone into a dry four-neck flask, stir, add 7.77g (0.067mol) of pyridine hydrochloride, heat up to 85°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane resistance | aaaaa | aaaaa |

| Membrane resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com