Cigarette packaging machine braking device and braking method

A braking device and packaging machine technology, applied in the direction of automatic packaging control, packaging, packaging cigarettes, etc., can solve problems such as affecting equipment efficiency, increasing consumption of auxiliary materials, increasing resistance, etc., to reduce equipment maintenance workload and broad market application prospects , Improve the effect of braking reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

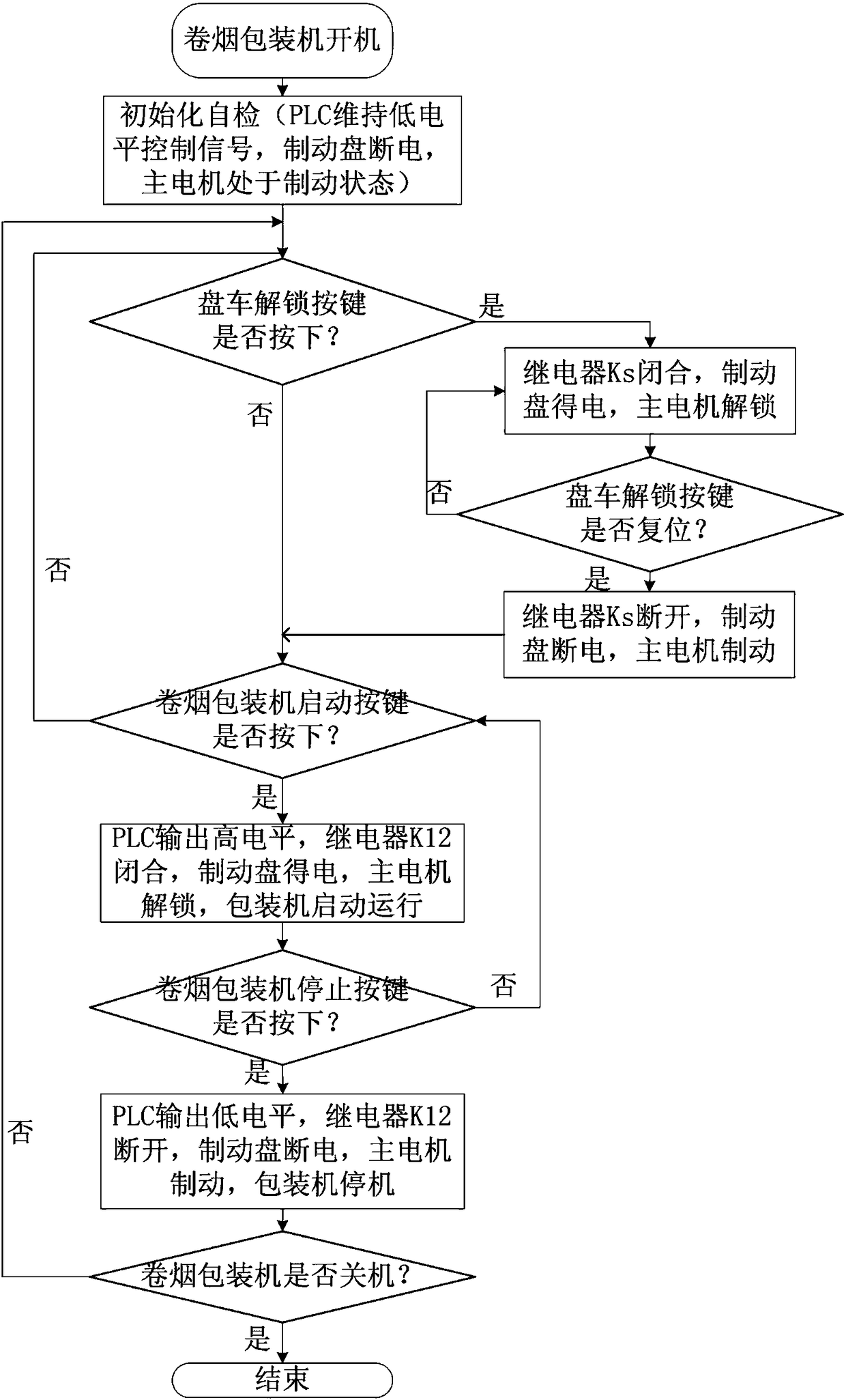

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

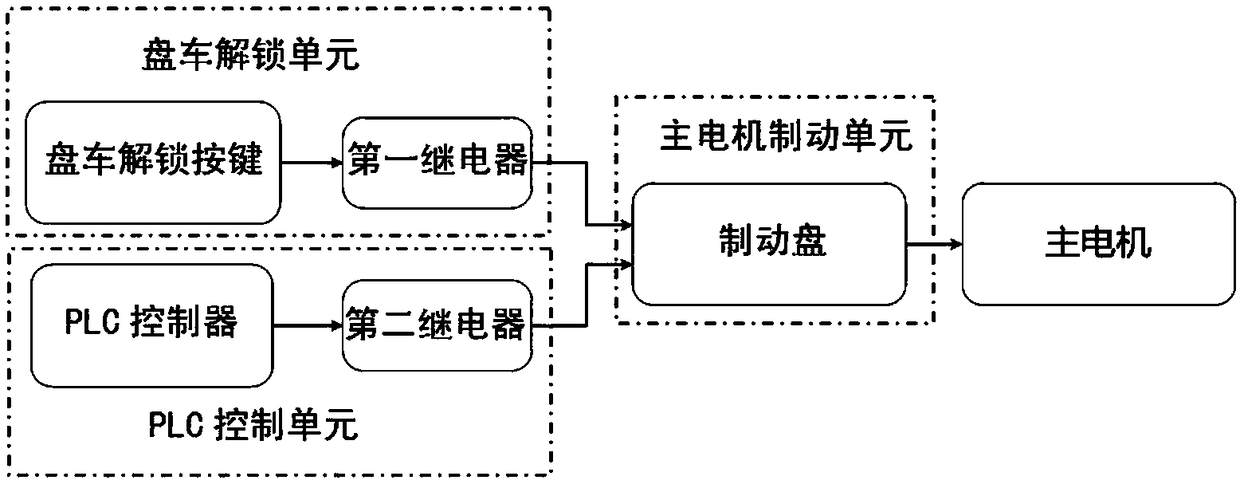

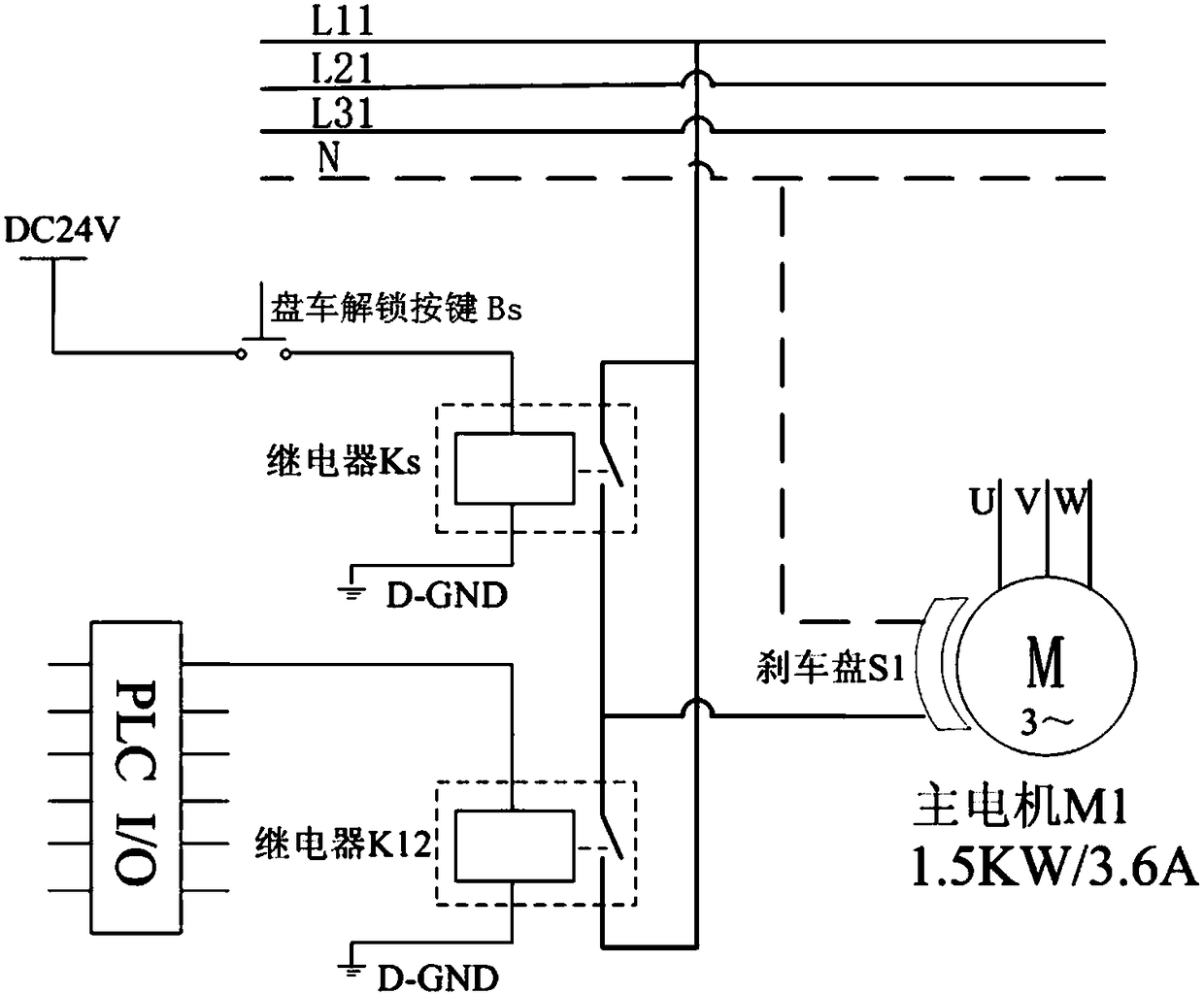

[0028] A cigarette packaging machine braking device described in the present invention belongs to a new generation of braking devices applied to cigarette packaging machine equipment, especially a braking device that can be specially applied to FHZ carton cigarette packaging machines, FHZ carton cigarette packaging The machine is a hard box packaging machine widely used in the prior art. It is driven by a traditional mechanical transmission system, and the gear transmission and cam transmission are driven by the main motor. The mechanism can work according to a strict action sequence, and the present invention proposes the braking device for the braking control of its main motor. first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com