Foundation construction technology

A construction technology and foundation technology, which is applied in basic structure engineering, road, soil protection and other directions, can solve problems such as poor waterproofness and wear resistance, water on the foundation, affecting the opening of the foundation to traffic, etc. The effect of releasing pressure and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

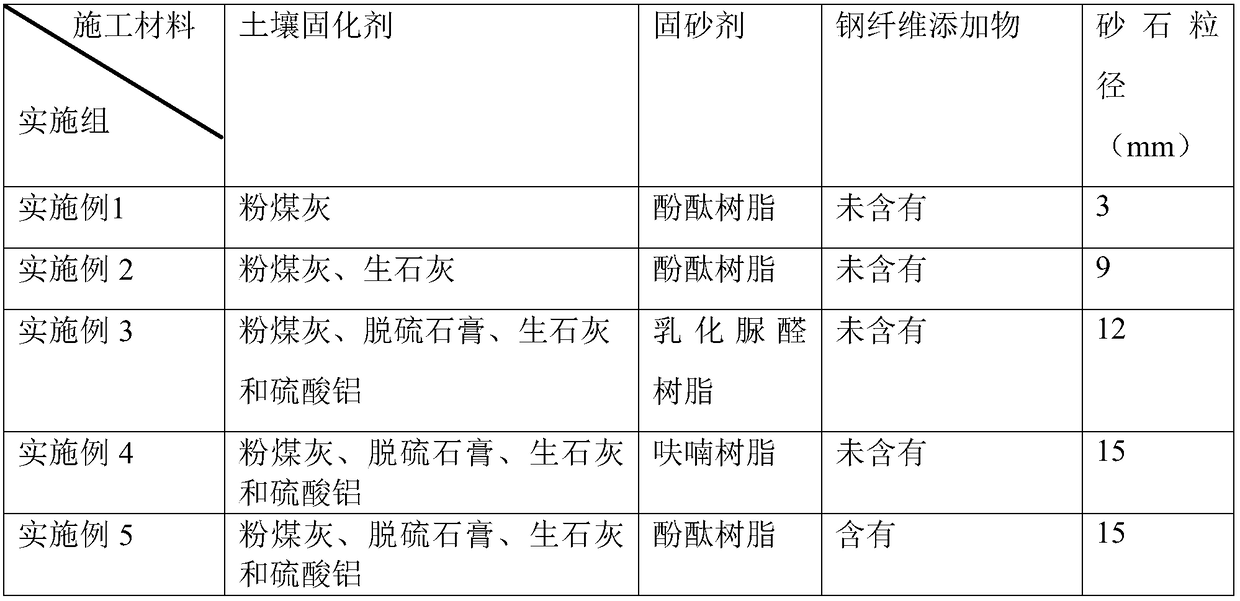

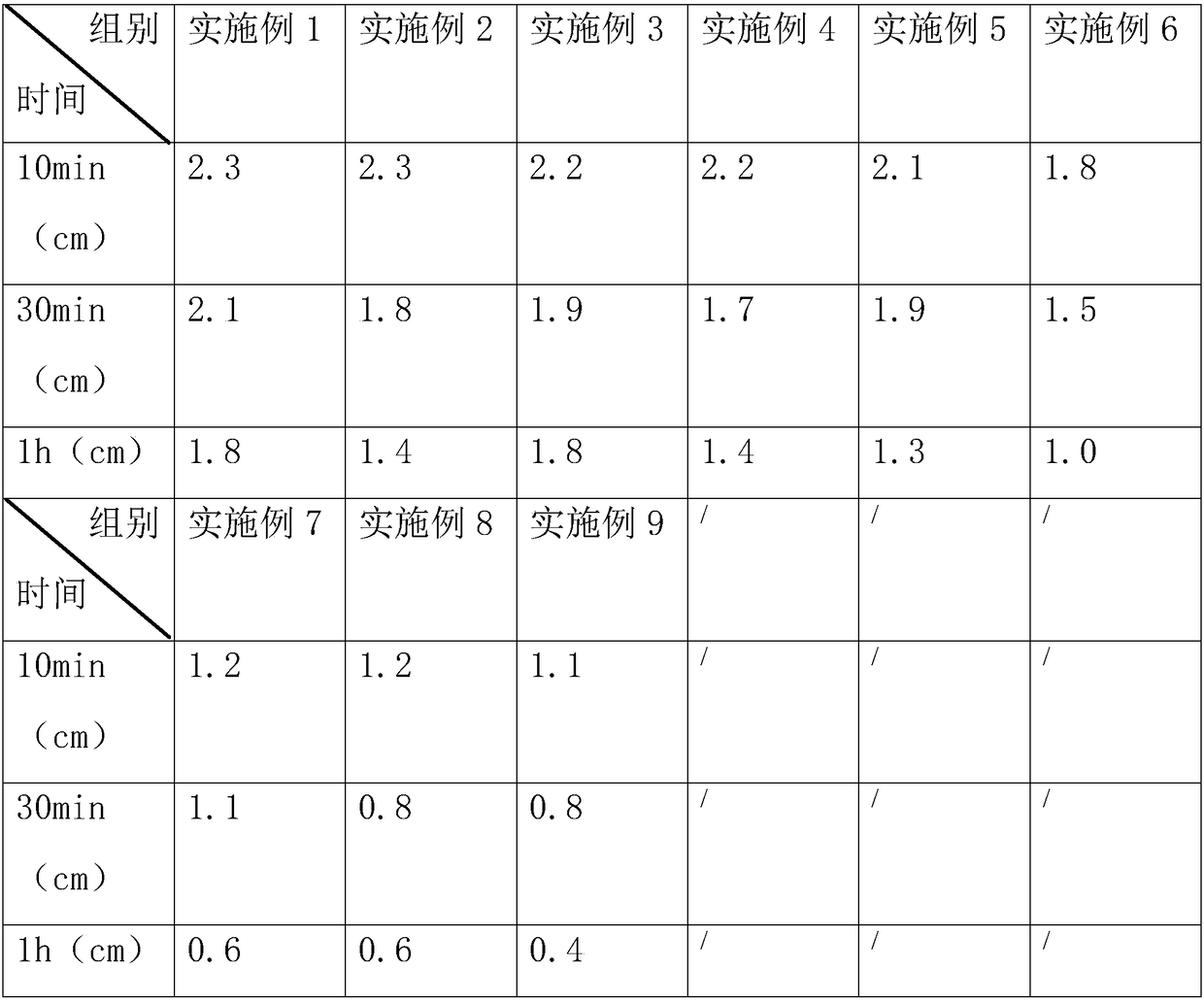

[0021] Embodiment 1-5, a kind of foundation construction technique, comprises the steps:

[0022] It mainly includes the following steps: step S1, spread the curing agent evenly on the surface of the subgrade foundation, and then use coarse sand and gravel to pave and roll it as a cushion; step S2, bind the reinforcement mesh layer on the cushion layer, and place Laying a layer of soluble film on top, and then evenly spreading the semi-rigid sub-base on the soluble film; step S3, laying a layer of water-permeable brick compaction layer on the upper surface of the semi-rigid sub-base; Spread the semi-rigid upper base evenly above the compaction layer; step S5, fill the mixed material layer of gravel and epoxy resin above the semi-rigid upper base and then compact it; step S6, after compacting the mixed material A layer of emulsified asphalt layer for fixing and bonding the epoxy resin layer is sprinkled on the layer. Wherein each component contained in embodiment 1-5 is as sho...

Embodiment 6

[0025] Embodiment 6, a foundation construction process, differs from Embodiment 5 in that, in the step S5, a waterproof adhesive layer is firstly laid on the semi-rigid upper base.

Embodiment 7

[0026] Embodiment 7, a foundation construction process, differs from Embodiment 5 in that the emulsified asphalt layer contains polymer fiber additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com