Design method of third-time-drilling well bore structure of narrow pressure window well in deep water

A pressure window and wellbore structure technology, applied in drilling equipment and methods, underwater drilling, drilling equipment, etc., can solve problems such as unreasonable drilling cost control, complicated wellbore structure for three times, etc. The effect of safe well control operation, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

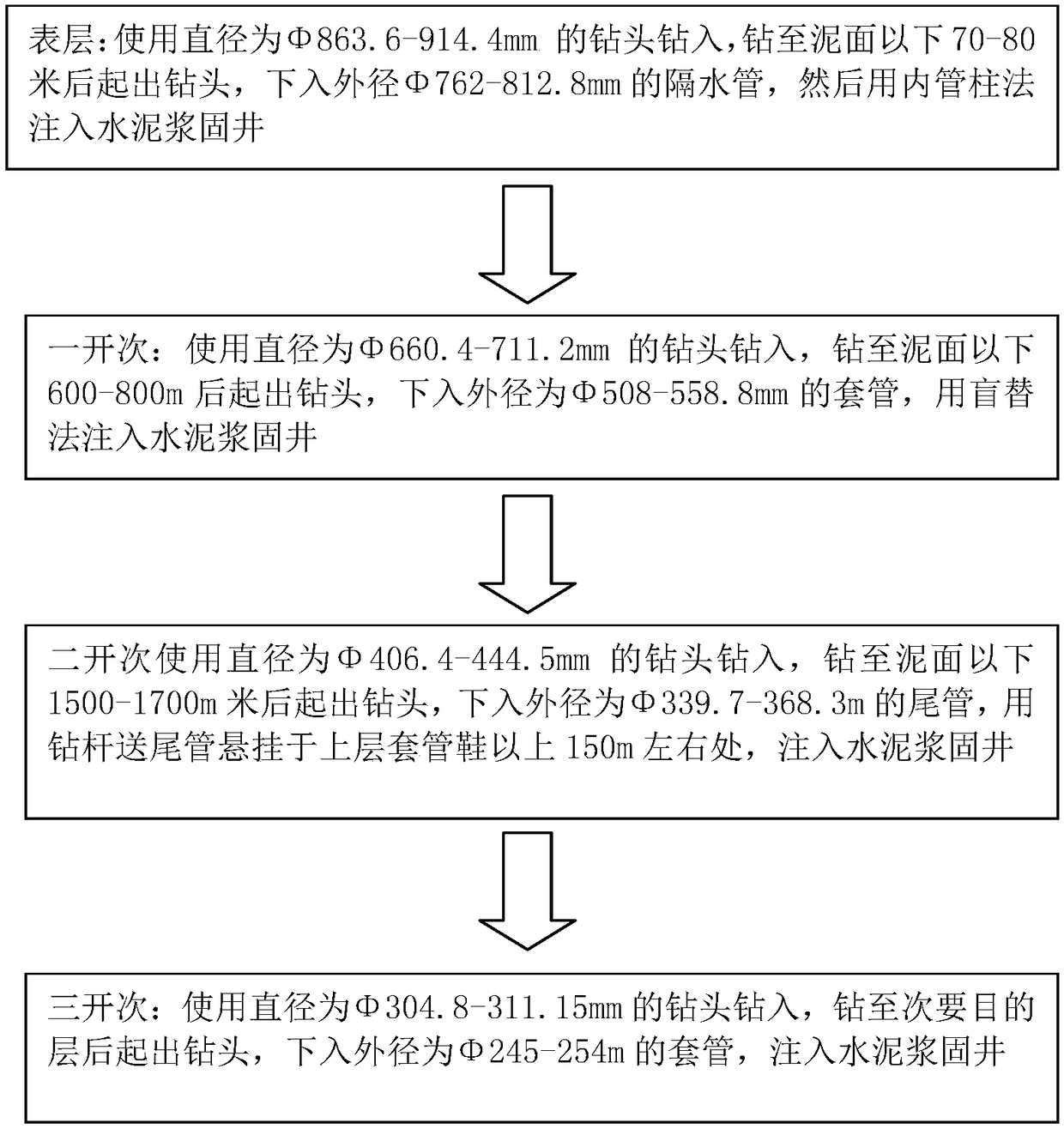

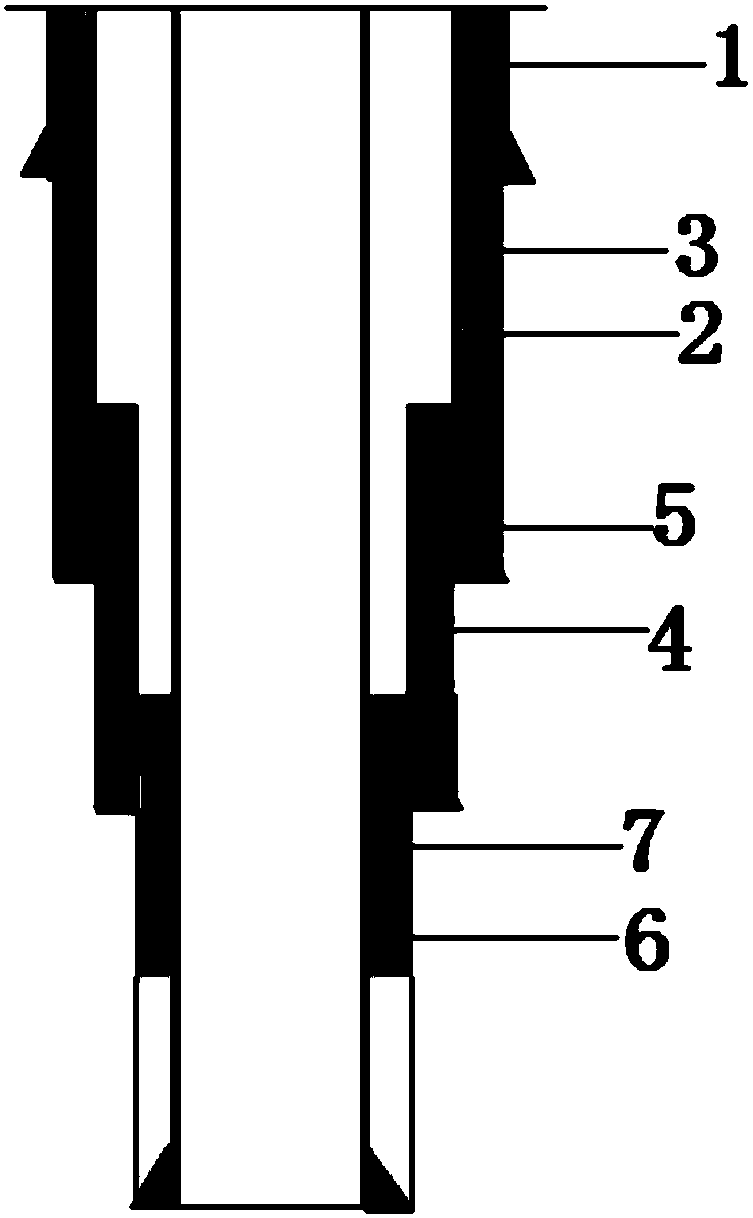

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0031] In order to implement the present invention, it is necessary to develop special size drill bits and reamers, and the development of drilling tools, casing heads, cementing tool accessories and testing tools that are matched with the corresponding borehole body structure. The specific contents are as follows:

[0032] 1. Special size drill bit and reamer

[0033] ① The surface layer adopts Φ660.4-711.2mm tri-cone bit + Φ863.6-914.4mm reamer;

[0034] ② Tri-cone drill bits with a diameter of Φ660.4-711.2mm are used for the first opening;

[0035] ③PDC drills with a diameter of Φ406.4-444.5mm are used for the second opening;

[0036] ④ PDC drills w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com