Drill rod connecting device

A connecting device and drill pipe technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of easy extrusion of soil, influence on joint installation, hardening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

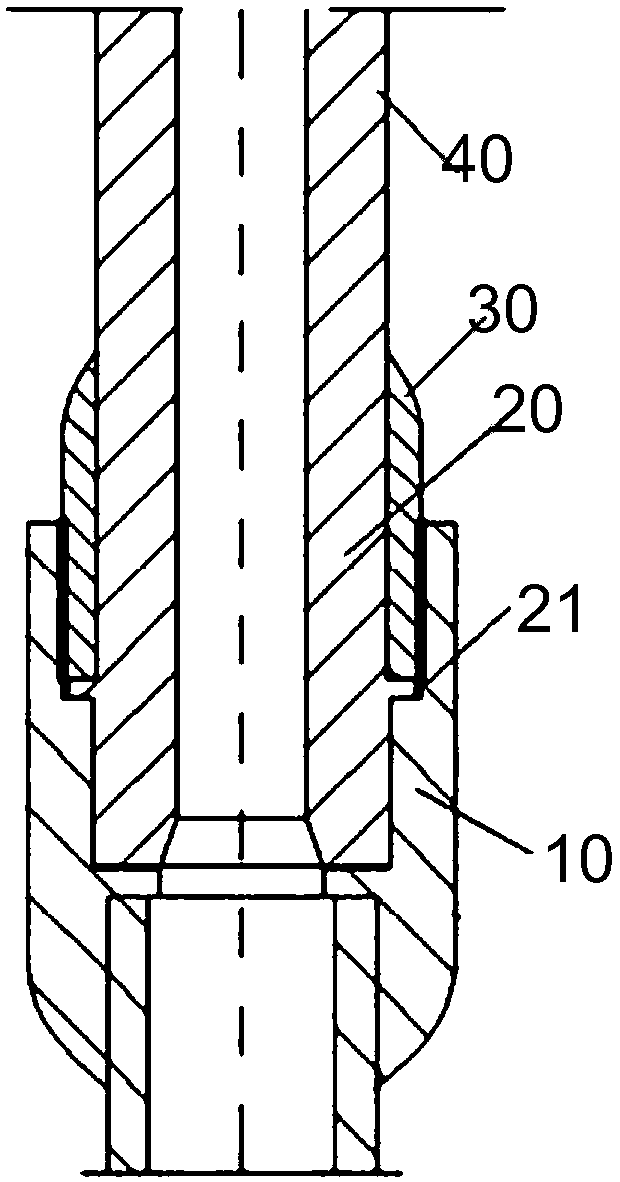

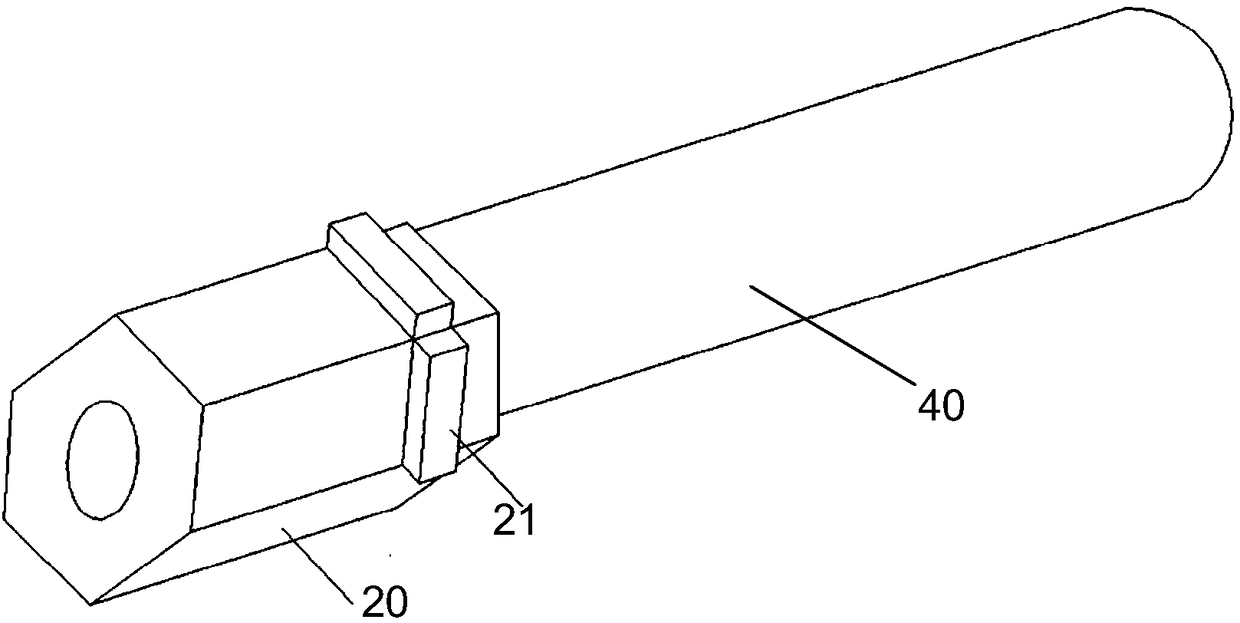

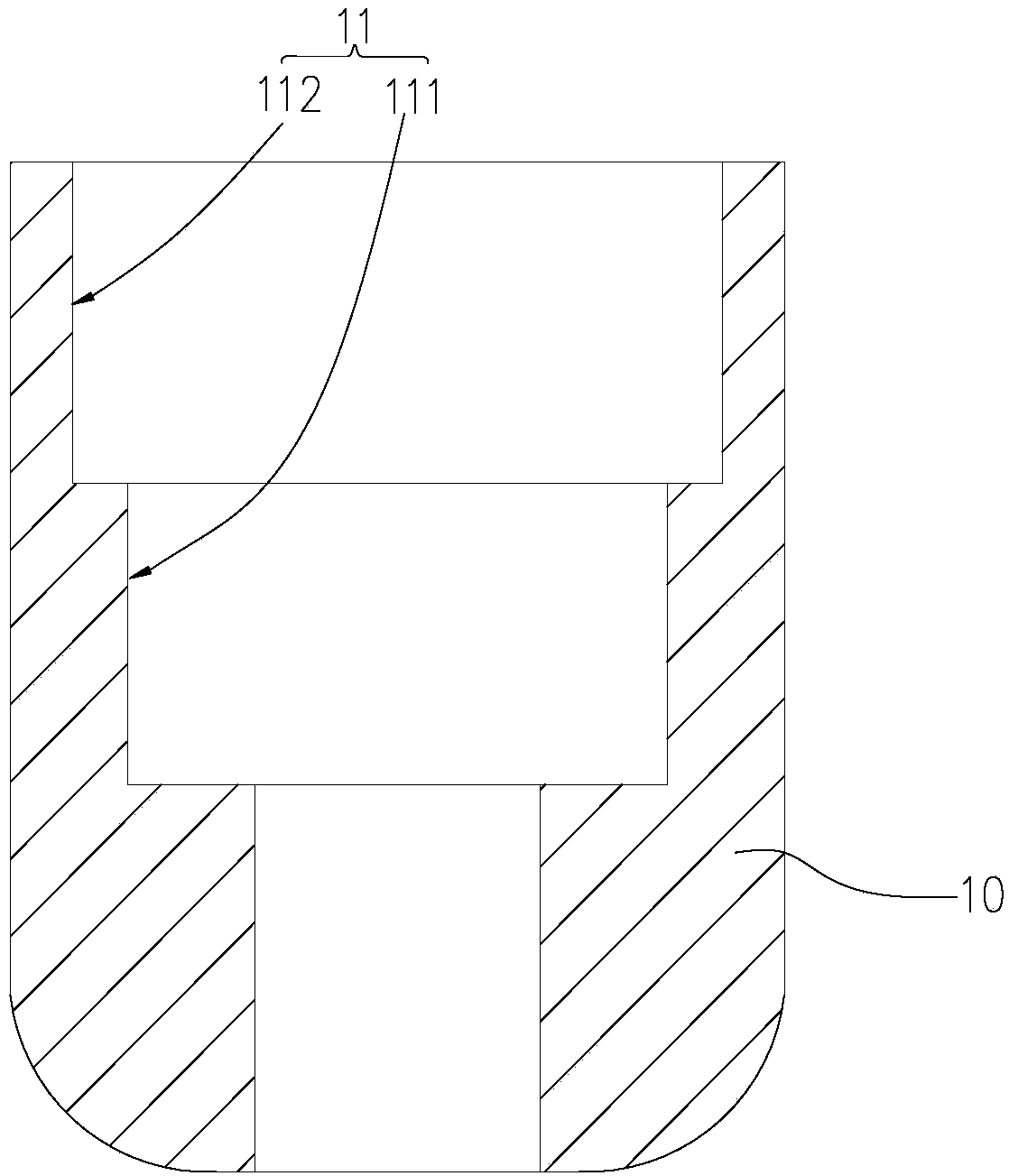

[0014] A drill pipe connection device, comprising a female joint 10 and a male joint 20, the male joint 20 is fixed at the end of the drill pipe 40, the female joint 10 is fixed on the drilling machine, and the male joint 20 is a polygonal cylinder structure, the middle part of the female joint 10 is provided with a stepped hole 11 for accommodating the male joint 20, the stepped hole 11 includes a polygonal hole section 111 and a threaded hole section 112, wherein the polygonal hole section 111 is located on the side close to the drilling machine, and the threaded hole section 112 The diameter of the hole is larger than the polygonal hole section 111, and the polygonal hole section 111 has the same shape and size as the cylindrical body of the male joint 20. The rod body of the drill pipe 40 is covered with a screw sleeve 30, and one end of the screw sleeve 30 is placed in the threaded hole. Section 112 and form a threaded engagement with it.

[0015] Insert the male joint 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com