Method for oxidative degradation of organic wastewater through low-grade thermal energy

A technology for organic wastewater and oxidative degradation, applied in chemical instruments and methods, oxidized water/sewage treatment, separation methods, etc., can solve the problems of high consumption of electric energy or chemical reagents, and high cost of organic wastewater treatment, and achieve simple manufacturing and reduced treatment Cost, effect of fewer moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

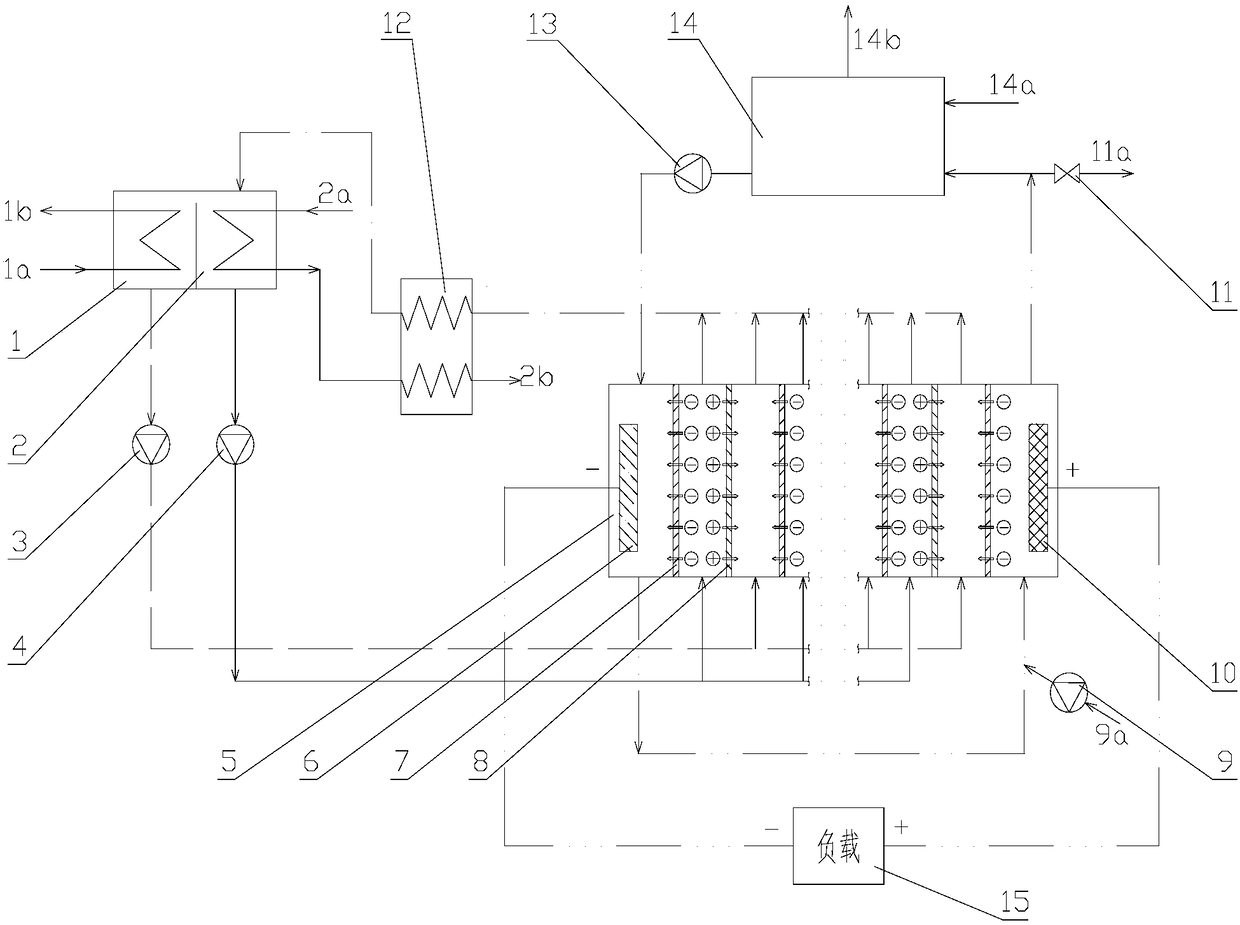

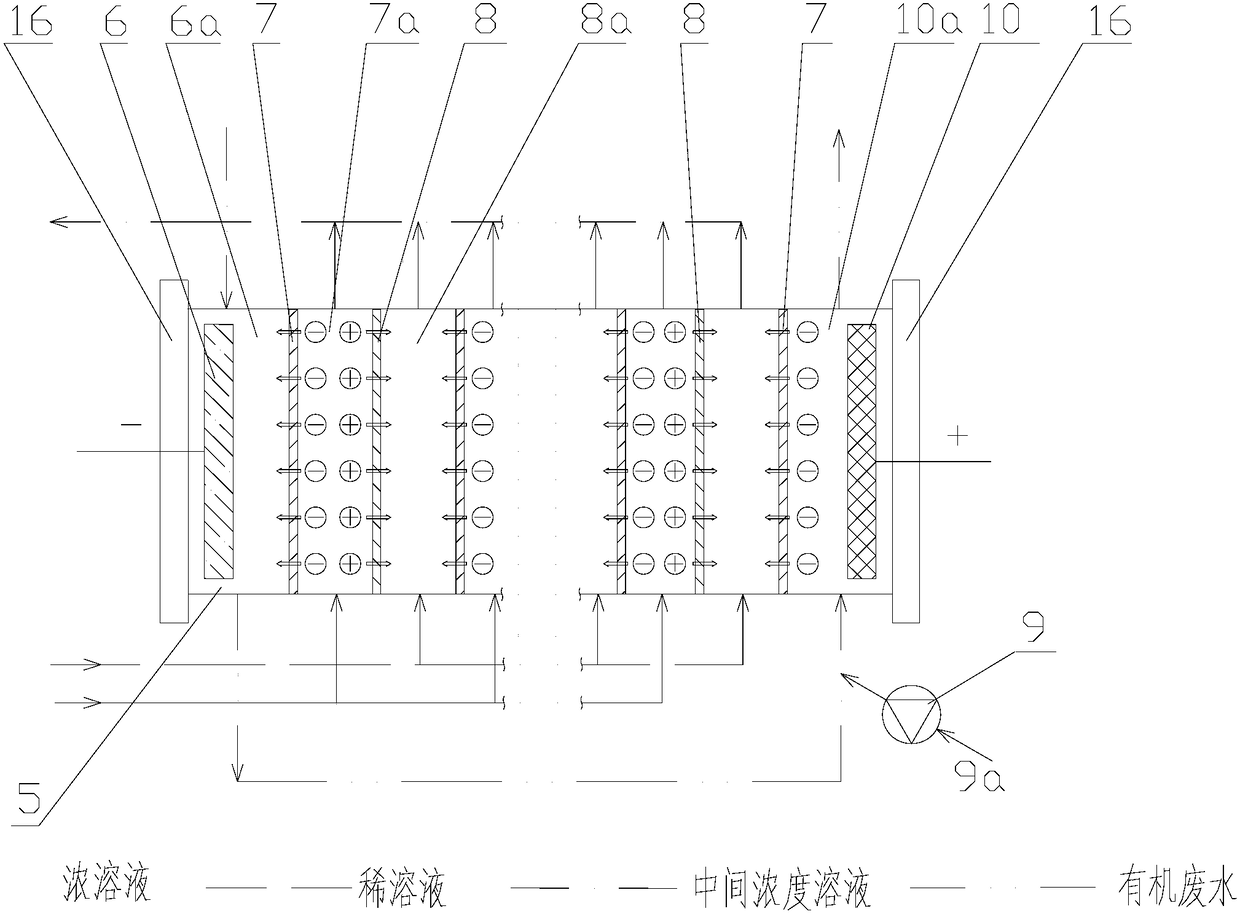

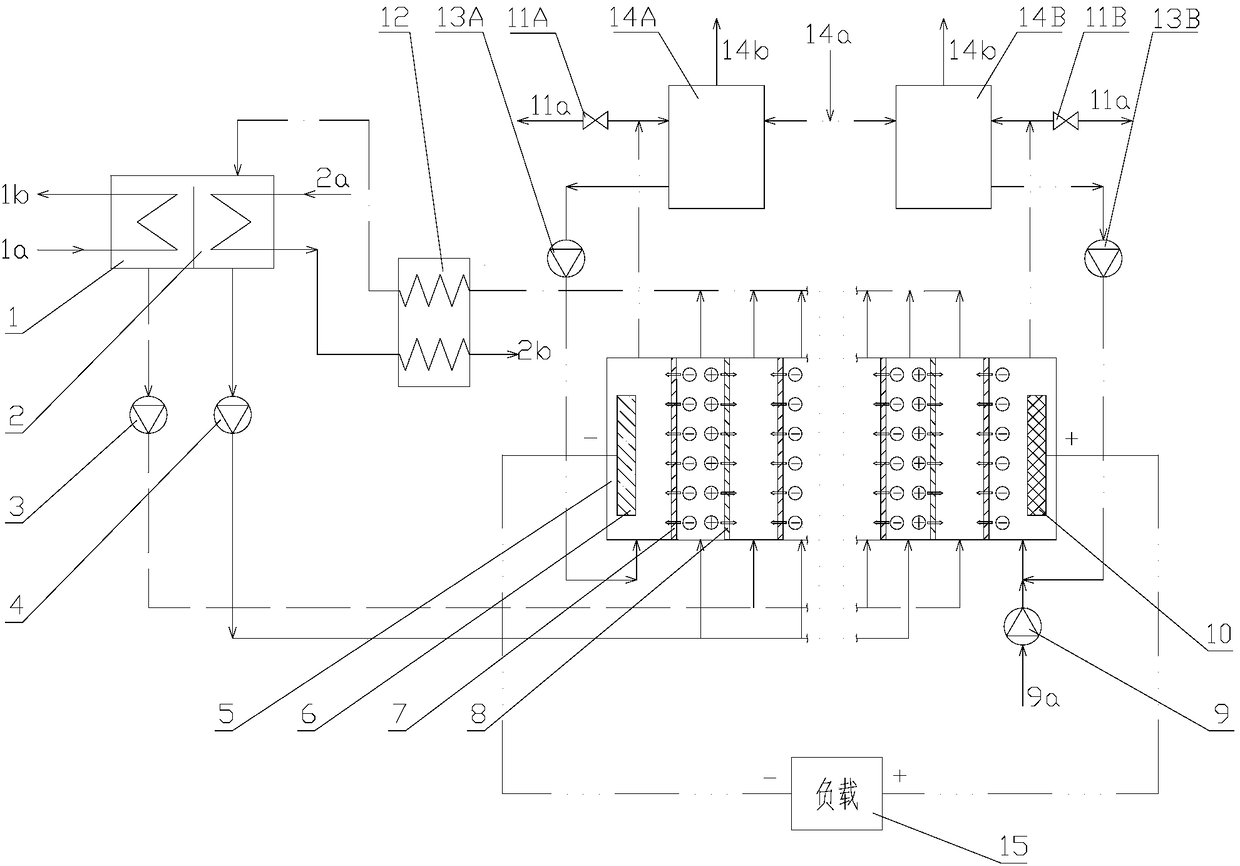

[0027] The specific implementation process of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0028] A novel low-grade thermal energy oxidation degradation method for organic wastewater, including the following two processes:

[0029] The first step: the process of converting low-grade thermal energy into chemical potential energy of the working solution.

[0030] First, use low-grade heat energy to heat the working solution in the distiller. Part of the low-boiling point components in the working solution evaporate from the solution and are separated and enter the condenser to be condensed into a liquid state by the cooling medium; The concentration increases to become a concentrated solution; the concentration difference between the concentrated solution and the dilute solution has a chemical potential energy difference. The working solution in this embodiment is sodium chloride, potassium chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com