A retarder suitable for sulphoaluminate cement

A technology of sulfoaluminate cement and setting retarder, applied in the field of setting retarder of sulfoaluminate cement, can solve problems such as the adverse effect of early strength of cement, and achieve the advantages of improving retarding effect, improving solubility and reducing surface tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

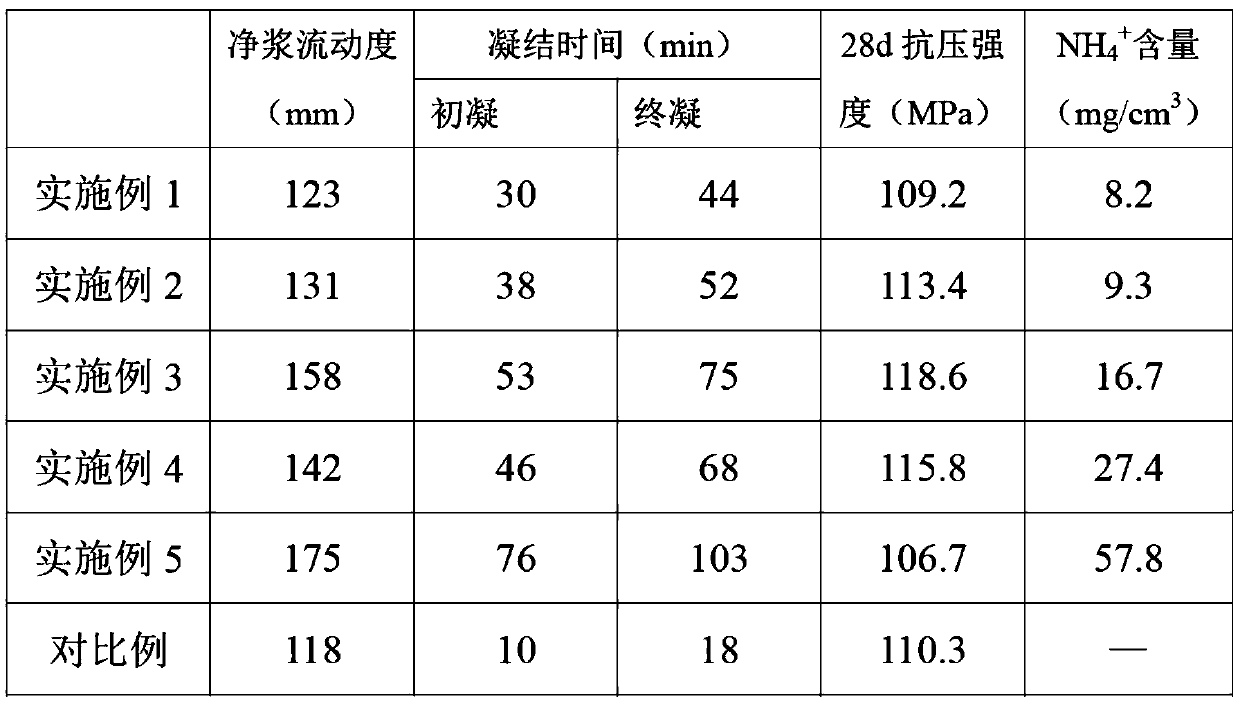

Examples

Embodiment 1

[0018] A high-efficiency retarder suitable for sulphoaluminate cement, which is composed of the following raw materials in parts by weight: 30 parts of isobutylene diurea (IBDU), 2 parts of sodium dioctyl succinate sulfonate, methylene 2 parts of disodium dinaphthalene sulfonate, 1 part of nitrification inhibitor.

[0019] A high-efficiency retarder suitable for sulphoaluminate cement is prepared by the following steps:

[0020] (1) Put isobutylidene diurea and nitrification inhibitor in a ball mill, mix and ball mill, test the sieve residue with a 200-mesh square hole sieve, when the sieve residue is ≤5%, stop the ball milling to obtain material 1;

[0021] (2) Put sodium dioctyl succinate sulfonate and disodium methylene bis-naphthalene sulfonate in a ball mill, mix and ball mill for 5 minutes, then cool for 10 minutes, and test the sieve with a 200-mesh square hole sieve, when the sieve ≤15%, get material 2;

[0022] (3) Put material 1 and material 2 together in a mixer, ...

Embodiment 2

[0024] A high-efficiency retarder suitable for sulphoaluminate cement, which is composed of the following raw materials in parts by weight: 40 parts of isobutylene diurea (IBDU), 4 parts of sodium dioctyl succinate sulfonate, methylene Disodium dinaphthalene sulfonate 4, nitrification inhibitor 2 parts.

[0025] The preparation method is the same as in Example 1.

Embodiment 3

[0027] A high-efficiency retarder suitable for sulphoaluminate cement, which is composed of the following raw materials in parts by weight: 50 parts of isobutylene diurea (IBDU), 6 parts of sodium dioctyl succinate sulfonate, methylene bis Disodium naphthalenesulfonate 6, nitrification inhibitor 3 parts.

[0028] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com