A new type of road polymer mixture and its preparation method

A mixture and polymer technology, which is applied in the field of new road polymer mixture and its preparation, can solve the problems of inability to form a continuous and effective adhesive layer, low BTA solid content, easy loose peeling, etc., to reduce loose peeling, The effect of increasing solid content and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

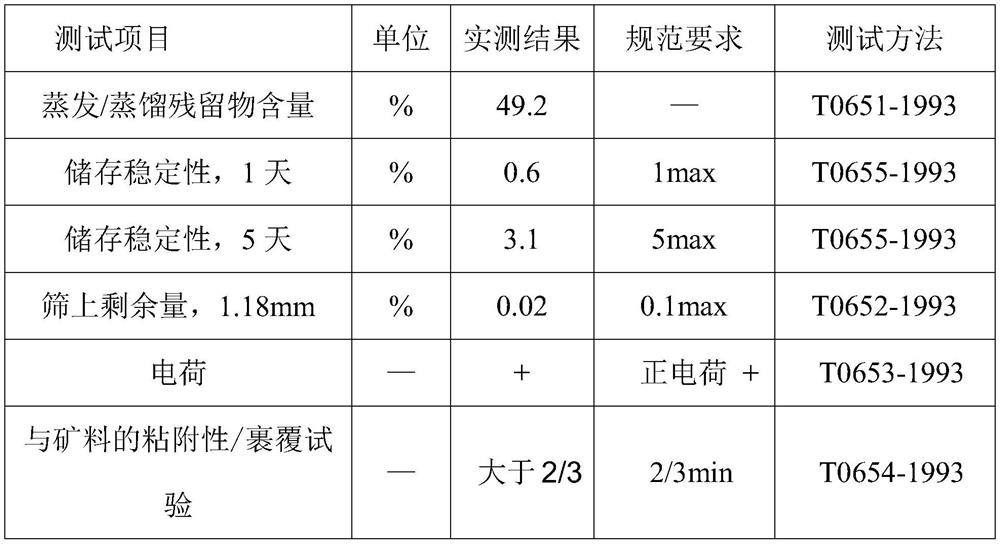

[0032] S1: Choose BTA-Ⅱ type mineral material gradation, choose limestone as mineral material, the added weight of emulsion and cement is calculated according to the percentage of the weight of the mixture: the amount of emulsion is 6%, BTA: emulsified asphalt = 8:2, the amount of cement is 4 %, according to the BTA-Ⅱ type mineral material gradation, carry out mineral material screening, weighing, and back-mixing. Weigh 188g of cement, 238g of BTA, and 60g of emulsified asphalt. The quality of each particle size of the mineral material is shown in Table 4:

[0033] Table 4 Example 1 Mineral material each particle size quality

[0034]

[0035] S2: In step S1, the ore powder is a mineral material with a particle size of less than 0.075mm. In step S1, all mineral materials with particle sizes other than mineral powder are added to the mixing pot, and 149g of water is added, and mixed evenly to make the mineral material wet surface;

[0036] Step S3: Add the new road water-ba...

Embodiment 2

[0043]S1: Choose BTA-Ⅱ for mineral material grading, limestone as mineral material, the added weight of emulsion and cement is calculated according to the percentage of the weight of the mixture: the amount of emulsion is 8%, BTA: emulsified asphalt = 5:5, and the amount of cement is 2 %, according to the BTA-Ⅱ type mineral material gradation, carry out mineral material screening, weighing, and back-mixing. Weigh 90g of cement, 198g of BTA, and 198g of emulsified asphalt. The quality of each particle size of the mineral material is shown in Table 6:

[0044] Table 6 Example 2 The mass of each particle size of the mineral material

[0045]

[0046] S2: In step S1, the ore powder is a mineral material with a particle size of less than 0.075mm. In step S1, all mineral materials with particle sizes other than mineral powder are added to the mixing pot, and 149g of water is added, and mixed evenly to make the mineral material wet surface;

[0047] Step S3: Add the new road wate...

Embodiment 3

[0054] S1: Choose BTA-Ⅱ for mineral material grading, limestone as mineral material, and the added weight of emulsion, cement, and lignin fiber are calculated according to the percentage of the weight of the mixture: the amount of emulsion is 8%, BTA: emulsified asphalt = 7:3 , cement consumption 2%, lignin fiber 0.45%, carry out mineral material screening, weighing, back-mixing according to BTA-Ⅱ type mineral material gradation, take cement 90g, BTA277g, emulsified asphalt 119g, lignin fiber=20g, The quality of each particle size of mineral materials is shown in Table 8:

[0055] The quality of each particle size of the ore material in the embodiment 3 of table 8

[0056]

[0057] S2: In step S1, the ore powder is a mineral material with a particle size of less than 0.075mm. In step S1, all mineral materials with particle sizes other than mineral powder are added to the mixing pot, and 149g of water is added, and mixed evenly to make the mineral material wet surface;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com