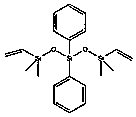

Preparation method of tetramethyl divinyl diphenyl trisiloxane

A technology of tetramethyldivinyldiphenyltrisiloxane and divinylsilazane, which is applied in the field of synthesizing organosilicon compounds, can solve the problems of low yield and difficult scale, and achieve high yield, It is convenient to observe the effect of the experimental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

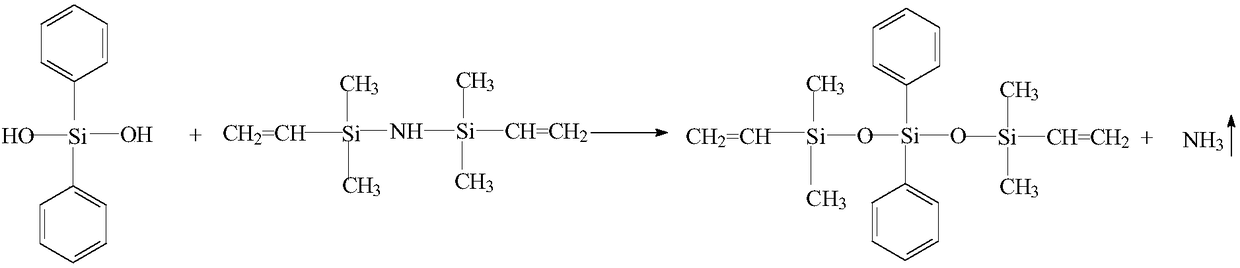

Method used

Image

Examples

Embodiment 1

[0025] Add 216g of n-heptane to a 2L dry four-necked flask equipped with a thermometer, a constant pressure dropping funnel, a stirrer, and a condenser, weigh 216g of diphenylsilanediol and add it to the flask to form a mixed dispersion. Slowly add 216g of 1,1,3,3-tetramethyl-1,3-divinylsilazane to the liquid funnel dropwise for 1 hour. After the dropwise addition, raise the temperature to 90°C and continue stirring for 2 hours. Pressure distillation, cut off the fraction at 140~144℃ / 1mmHg to obtain a colorless transparent liquid, which is tetramethyldivinyldiphenyltrisiloxane. Weighing 357g, the yield is 92.97%, and the chromatographic detection content is 99.46%.

Embodiment 2

[0027] Add 250g of n-heptane to a 2L dry four-necked flask equipped with a thermometer, a constant pressure dropping funnel, a stirrer, and a condenser tube, weigh 216g of diphenylsilanediol and add it to the flask to form a mixed dispersion. Slowly add 222g of 1,1,3,3-tetramethyl-1,3-divinylsilazane dropwise into the liquid funnel for 1.5 hours. After the dropwise addition, raise the temperature to 100°C and continue stirring for 2 hours. The system becomes transparent. Distill under reduced pressure and cut off the fraction at 140~144℃ / 1mmHg to obtain a colorless transparent liquid, which is tetramethyldivinyldiphenyltrisiloxane. Weighing 362g, the yield is 94.27%, and the chromatographic detection content is 99.51%.

Embodiment 3

[0029] Add 280g of n-heptane to a 2L dry four-necked flask equipped with a thermometer, a constant pressure dropping funnel, a stirrer, and a condenser tube, weigh 216g of diphenylsilanediol and add it to the flask to form a mixed dispersion. Slowly add 250g of 1,1,3,3-tetramethyl-1,3-divinylsilazane dropwise into the liquid funnel for 1 hour. After the dropwise addition, raise the temperature to 120°C and continue stirring for 3 hours. Pressure distillation, cut off the fraction at 140~144℃ / 1mmHg to obtain a colorless transparent liquid, which is tetramethyldivinyldiphenyltrisiloxane. Weighing 368g, the yield is 95.58%, and the chromatographic detection content is 99.56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com