Preparation method for hexamethylenediphenyl trisiloxane

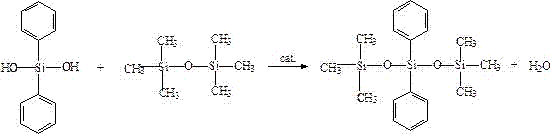

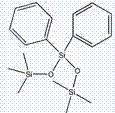

A technology of hexamethyldiphenyltrisiloxane and hexamethyldisiloxane is applied in the field of synthesizing organosilicon compounds, and can solve the problem of low yield, difficult hexamethyldiphenyltrisiloxane, It is difficult to scale and other problems to achieve the effect of high yield and easy observation of experimental results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 432g of n-heptane to a 2L dry four-neck flask equipped with a thermometer, a constant pressure dropping funnel, a stirrer, and a condenser, weigh 216g of diphenylsilanediol, 21.6g of a strong acid cationic resin (trade name LDX-604 ) into the flask to form a mixed dispersion. Slowly add 216g of hexamethyldisiloxane dropwise through a constant pressure dropping funnel for 1 hour. After the dropwise addition, raise the temperature to 70°C and continue stirring for 2 hours. After reaching room temperature, filter out the strongly acidic cationic resin, distill the filtrate under reduced pressure, and intercept the fraction at 172°C / 18mmHg to obtain a colorless transparent liquid, which is hexamethyldiphenyltrisiloxane. Weighing 331g, the yield is 91.94%, and the chromatographic detection content is 99.76%.

Embodiment 2

[0029] Add 648g of n-heptane to a 2L dry four-neck flask equipped with a thermometer, a constant pressure dropping funnel, a stirrer, and a condenser, weigh 216g of diphenylsilanediol, 32.4g of a strong acid cationic resin (trade name LDX-604 ) into the flask to form a mixed dispersion. Slowly add 260g of hexamethyldisiloxane dropwise through the constant pressure dropping funnel for 1 hour. After the dropwise addition, raise the temperature to 50°C and continue stirring for 3 hours. After reaching room temperature, filter out the strongly acidic cationic resin, distill the filtrate under reduced pressure, and intercept the fraction at 172°C / 18mmHg to obtain a colorless transparent liquid, which is hexamethyldiphenyltrisiloxane. Weighing 326g, the yield is 90.56%, and the chromatographic detection content is 99.56%.

Embodiment 3

[0031] Add 864g of n-heptane to a 2L dry four-neck flask equipped with a thermometer, a constant pressure dropping funnel, a stirrer, and a condenser, weigh 216g of diphenylsilanediol, and 43.2g of a strongly acidic cationic resin (trade name LDX-604 ) into the flask to form a mixed dispersion. Slowly add 324g of hexamethyldisiloxane dropwise through the constant pressure dropping funnel for 2 hours. After the dropwise addition, raise the temperature to 60°C and continue stirring for 2 hours. After reaching room temperature, filter out the strongly acidic cationic resin, distill the filtrate under reduced pressure, and intercept the fraction at 172°C / 18mmHg to obtain a colorless transparent liquid, which is hexamethyldiphenyltrisiloxane. Weighing 333g, the yield is 92.50%, and the chromatographic detection content is 99.61%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com