Special material for electrostatic discharge floor and preparation method of material

An anti-static floor and special material technology, applied in the field of floor manufacturing, can solve the problems of high cost and expensive raw material silver nanowires, and achieve the effect of improving permanent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1: A special material for antistatic flooring, the components and their corresponding parts by weight are shown in Table 2, and are prepared through the following steps:

[0062] S1: Weigh 8g of epoxidized soybean oil and 7g of dioctyl terephthalate and mix them uniformly to obtain mixture 1; S2: Weigh 0.2g of lubricant, 85g of light calcium carbonate and 100g of PVC resin and mix Obtain mixture 2 evenly;

[0063]S3: Weigh 15g of chlorinated polyethylene modified resin, 6g of environmental protection antistatic agent, 5g of calcium-zinc stabilizer, 2g of titanium dioxide, and mix uniformly with mixture 1 obtained in S1 and mixture 2 obtained in S2 to obtain mixture 3;

[0064] S4: The mixture three is granulated at 135° C. to obtain the required antistatic floor special material. The lubricant is all composed of lubricant G32, and the particle size of the light calcium carbonate is between 1 and 5 μm. The manufacturers of each component are shown in Table 1.

...

Embodiment 2-4

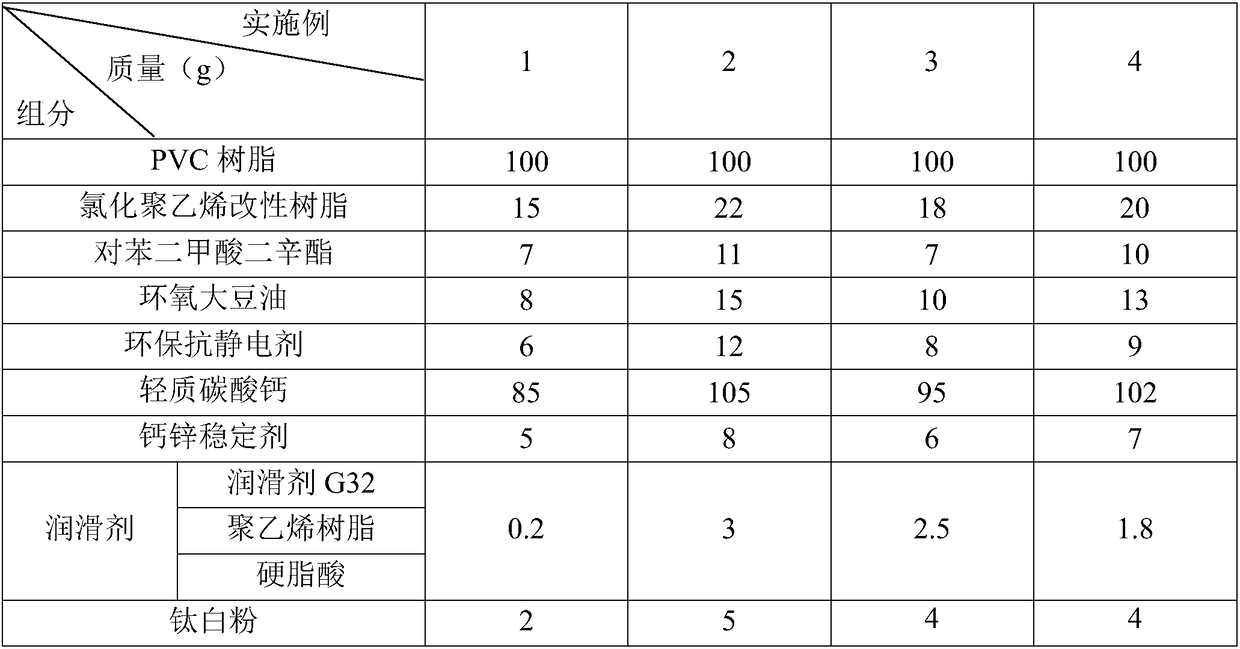

[0067] Embodiment 2-4: The difference from Embodiment 1 is that each component and its corresponding quality are shown in Table 2.

[0068] Each component and its corresponding quality in table 2 embodiment 1-4

[0069]

Embodiment 5

[0070] Example 5: A special material for antistatic flooring. The difference from Example 4 is that the lubricant is all composed of polyethylene resin, and the manufacturers of each component are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com