Acrylate structural adhesive for bonding aluminum shell for flame-retardant power battery and preparation method of acrylate structural adhesive

A power battery and acrylate technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of a large number of pores and lines on the surface of the adhesive layer, reduced battery safety performance, uncontrollable heat generation, etc. problem, achieve the effect of avoiding danger caused by heat accumulation, reducing heat, and lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

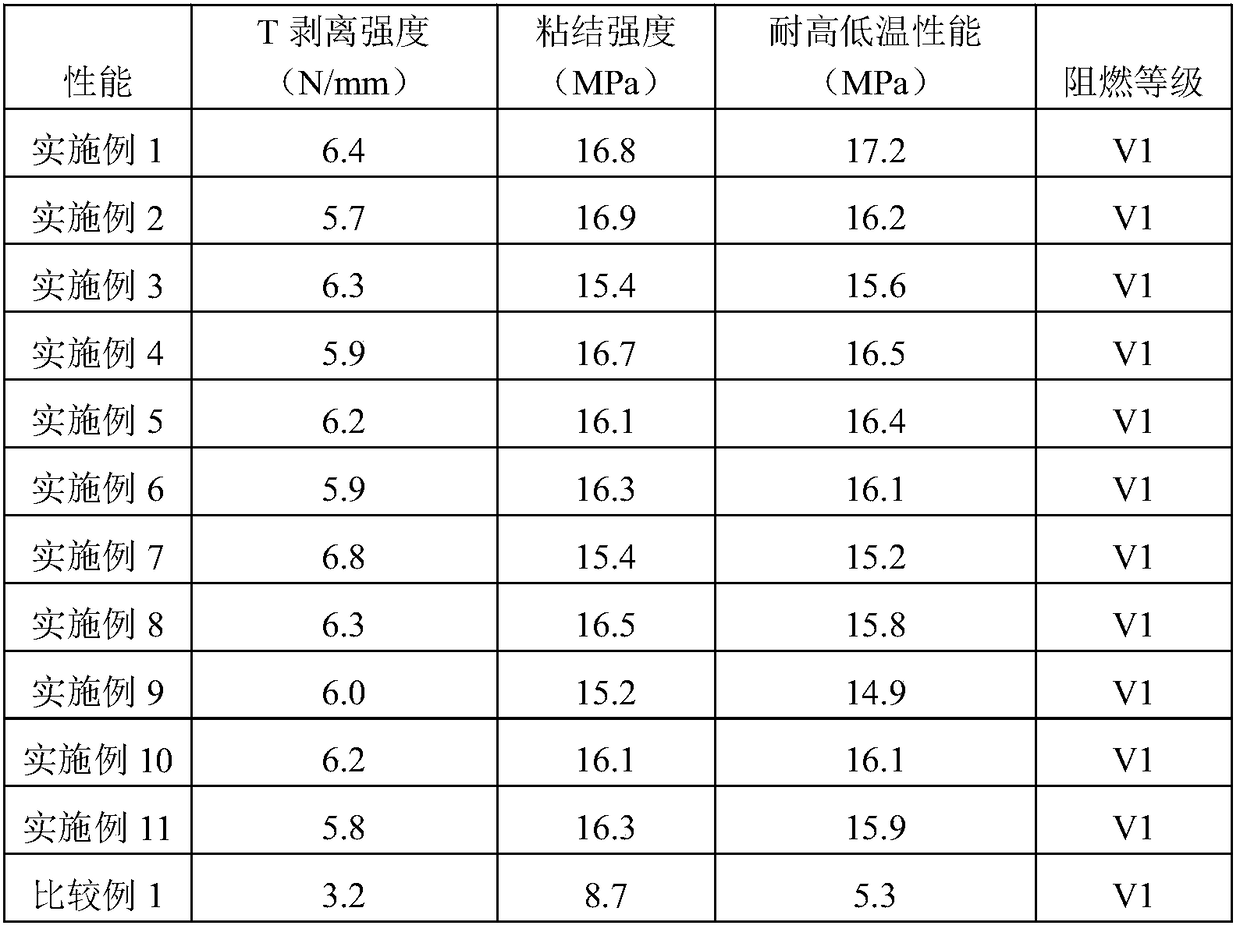

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing the acrylate structural adhesive bonded to the aluminum case of the flame-retardant power battery as described above, which includes the following steps:

[0050] Prepare the oxidizing agent component and the reducing agent component, and the sequence of preparing the oxidizing agent component and the reducing agent component is not limited;

[0051] The preparation method of the oxidant component is: adding isobornyl methacrylate, 2-phenoxyethyl acrylate, 3,3,5-trimethylcycloethane methacrylate and nitrile rubber into the dynamic mixer Inside, stir at high speed until the nitrile rubber is completely dissolved, add methyl methacrylate-butyl acrylate diblock copolymer, flame retardant and stabilizer, stir at high speed for 0.5 to 1 hour, then add peroxide, stir at low speed for 0.5 ~1 hour to obtain the oxidizing agent component;

[0052] The preparation method of the reducing agent component is: adding tetrahy...

Embodiment 1

[0057] Add 30 parts of isobornyl methacrylate, 12 parts of 2-phenoxyethyl acrylate, 8 parts of 3,3,5-trimethylcycloethane methacrylate and 10 parts of nitrile rubber into the dynamic mixer Inside, stir at high speed until the nitrile rubber is completely dissolved, add 8 parts of methyl methacrylate-butyl acrylate diblock copolymer, 25 parts of flame retardant and 2 parts of stabilizer, stir at high speed for 0.5 to 1 hour, then add 5 Parts of peroxide, stirred at low speed for 0.5 to 1 hour to obtain the oxidizing agent component;

[0058] Add 35 parts of tetrahydrofurfuryl alcohol methacrylate, 8 parts of isooctyl methacrylate, 6 parts of 2-hydroxyethyl methacrylate phosphate and 8 parts of carboxyl-terminated neoprene rubber into the dynamic mixer, and stir at high speed Until the carboxyl-terminated modified chloroprene rubber is completely dissolved, add 8 parts of methyl methacrylate-butyl acrylate diblock copolymer, 28 parts of flame retardant, 2 parts of auxiliary agen...

Embodiment 2

[0061] Add 40 parts of isobornyl methacrylate, 15 parts of 2-phenoxyethyl acrylate, 5 parts of 3,3,5-trimethylcycloethane methacrylate and 5 parts of nitrile rubber into the dynamic mixer Inside, stir at high speed until the nitrile rubber is completely dissolved, add 10 parts of methyl methacrylate-butyl acrylate diblock copolymer, 15 parts of flame retardant and 4 parts of stabilizer, stir at high speed for 0.5 to 1 hour, then add 6 Parts of peroxide, stirred at low speed for 0.5 to 1 hour to obtain the oxidizing agent component;

[0062] Add 40 parts of tetrahydrofurfuryl alcohol methacrylate, 5 parts of isooctyl methacrylate, 8 parts of 2-hydroxyethyl methacrylate phosphate and 5 parts of carboxyl-terminated neoprene into the dynamic mixer, high speed Stir until the carboxyl-terminated modified chloroprene rubber is completely dissolved, add 10 parts of methyl methacrylate-butyl acrylate diblock copolymer, 20 parts of flame retardant, 5 parts of auxiliary agent and 2 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com