Preparation method of high-strength low-cost titanium-base amorphous alloy

An amorphous alloy, low-cost technology, applied in the field of biomedicine, can solve the problems of insufficient strength and high cost, and achieve the effect of large fracture strength, small elastic modulus, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

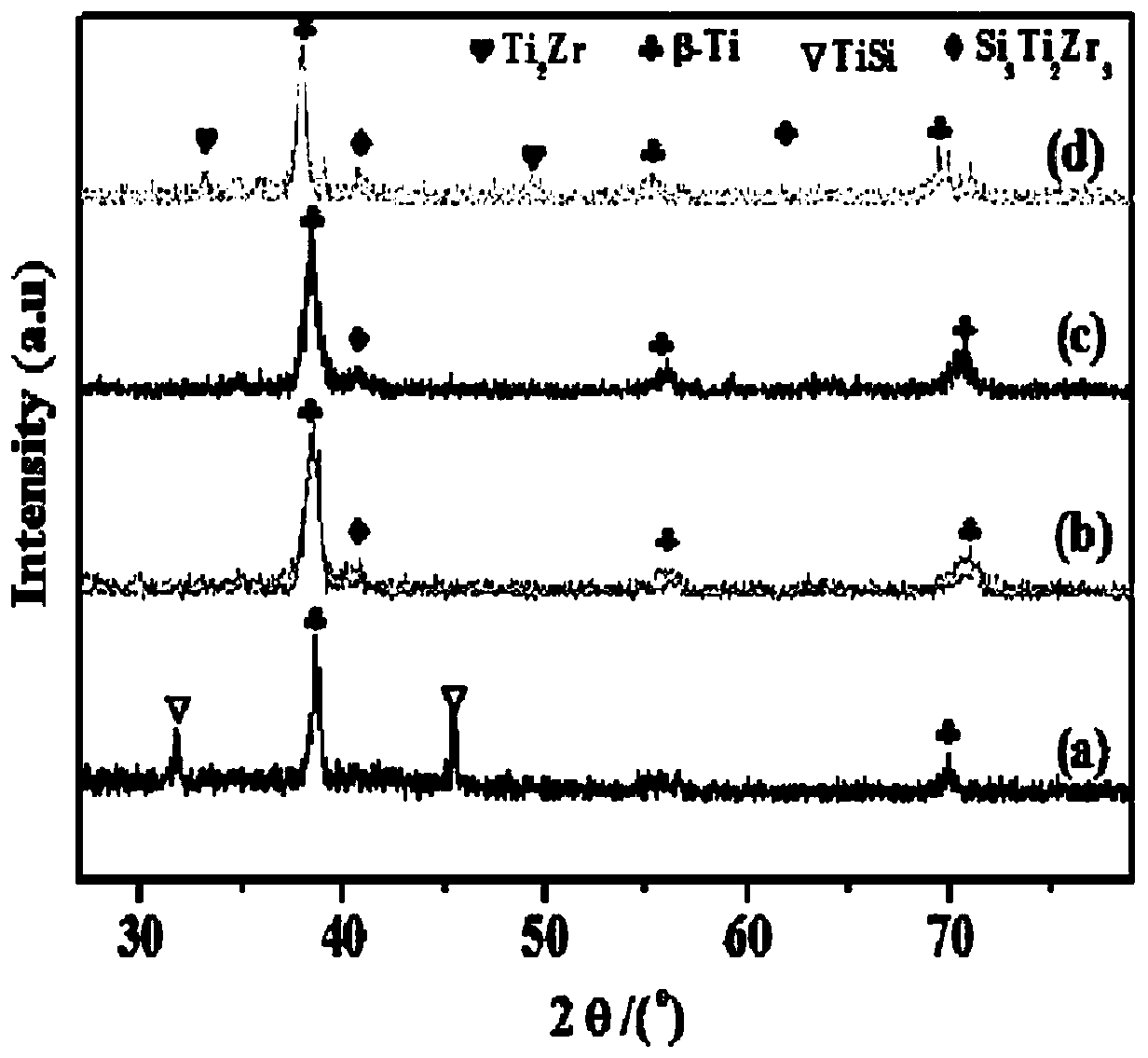

Embodiment 1

[0023] A method for preparing a high-strength and low-cost titanium-based amorphous alloy, comprising the following steps:

[0024] (1) Ti (Ti content ≥99%), Zr (Zr content ≥99%), Ta (Ta content ≥99%), Si (Si content ≥99%) and Nb (Nb content ≥ 99%) respectively by Ti 60 Zr 10 Si 15 Ta 15-x Nb x (x= 3at. %) nominal group ratio;

[0025] (2) First smelt Ta and Si together to form an intermediate alloy with a melting point of 2533 K; then smelt the remaining Si with Nb to form an intermediate alloy with a melting point of 2193 K; smelt pure Ti, pure Zr, remaining Si, and Ta Si The alloy and the Si Nb master alloy are smelted repeatedly for 3 times in an electric arc furnace in an atmosphere of high-purity argon, and smelted into a master alloy;

[0026] (3) After the master alloy is melted, it enters the water-cooled copper mold by suction casting to cool to form an amorphous alloy with a diameter of 2.5mm.

Embodiment 2

[0028] A method for preparing a high-strength and low-cost titanium-based amorphous alloy, comprising the following steps:

[0029] (1) Ti (Ti content ≥99%), Zr (Zr content ≥99%), Ta (Ta content ≥99%), Si (Si content ≥99%) and Nb (Nb content ≥ 99%) respectively by Ti 60 Zr 10 Si 15 Ta 15-x Nb x (x= 7at. %) nominal composition ratio;

[0030] (2) First smelt Ta and Si together to form a master alloy with a melting point of 2545K; then smelt the remaining Si with Nb to form a master alloy with a melting point of 2200 K; smelt pure Ti, pure Zr, remaining Si, Ta Si master alloy and Si Nb master alloy are smelted repeatedly 4 times in an electric arc furnace under the atmosphere of high-purity argon, and smelted into a master alloy;

[0031] (3) After the master alloy is melted, it enters the water-cooled copper mold by suction casting to cool to form an amorphous alloy with a diameter of 3.0mm.

Embodiment 3

[0033] A method for preparing a high-strength and low-cost titanium-based amorphous alloy, comprising the following steps:

[0034] (1) Ti (Ti content ≥99%), Zr (Zr content ≥99%), Ta (Ta content ≥99%), Si (Si content ≥99%) and Nb (Nb content ≥ 99%) according to the nominal composition ratio of Ti60Zr10Si15Ta15-x Nbx (x=11at. %);

[0035] (2) First smelt Ta and Si together to form an intermediate alloy with a melting point of 2540 K; then smelt the remaining Si with Nb to form an intermediate alloy with a melting point of 2199 K; smelt pure Ti, pure Zr, remaining Si, and Ta Si The alloy and the Si Nb master alloy are smelted repeatedly in an electric arc furnace for 5 times in an atmosphere of high-purity argon, and smelted into a master alloy;

[0036] (3) After the master alloy is melted, it is sucked into the water-cooled copper mold and cooled to form an amorphous alloy with a diameter of 3.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com