Multi-station continuous machining production line after steel pipe hot-dip galvanizing

A hot-dip galvanizing, multi-station technology, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve the problem of low integration of process links, increase production costs of enterprises, and consume a lot of labor resources, etc. problems, to achieve the effect of close and coherent water cooling treatment links, improved production efficiency, and less labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structure and working principle of the multi-station continuous processing production line for steel pipes after hot-dip galvanizing provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

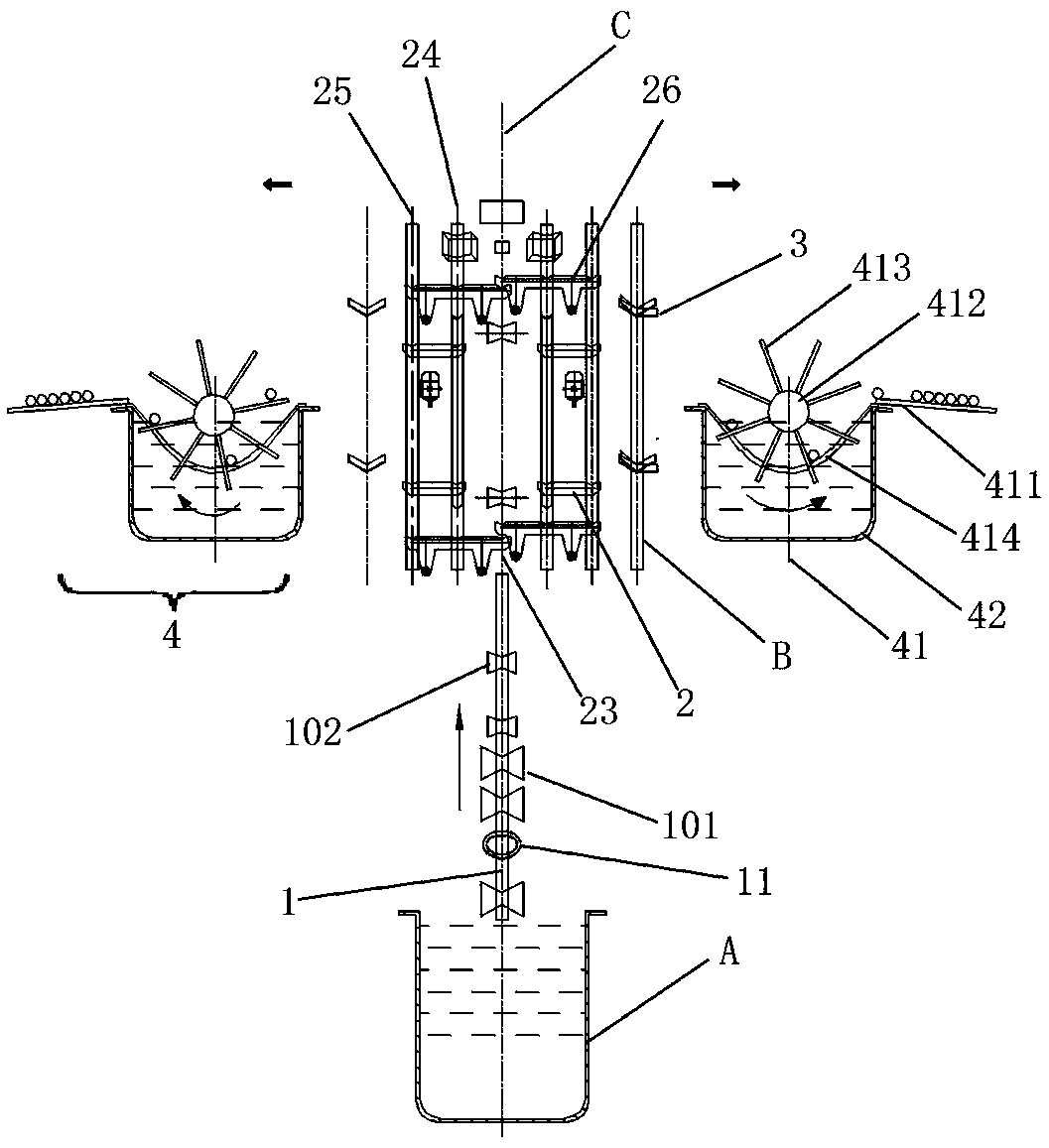

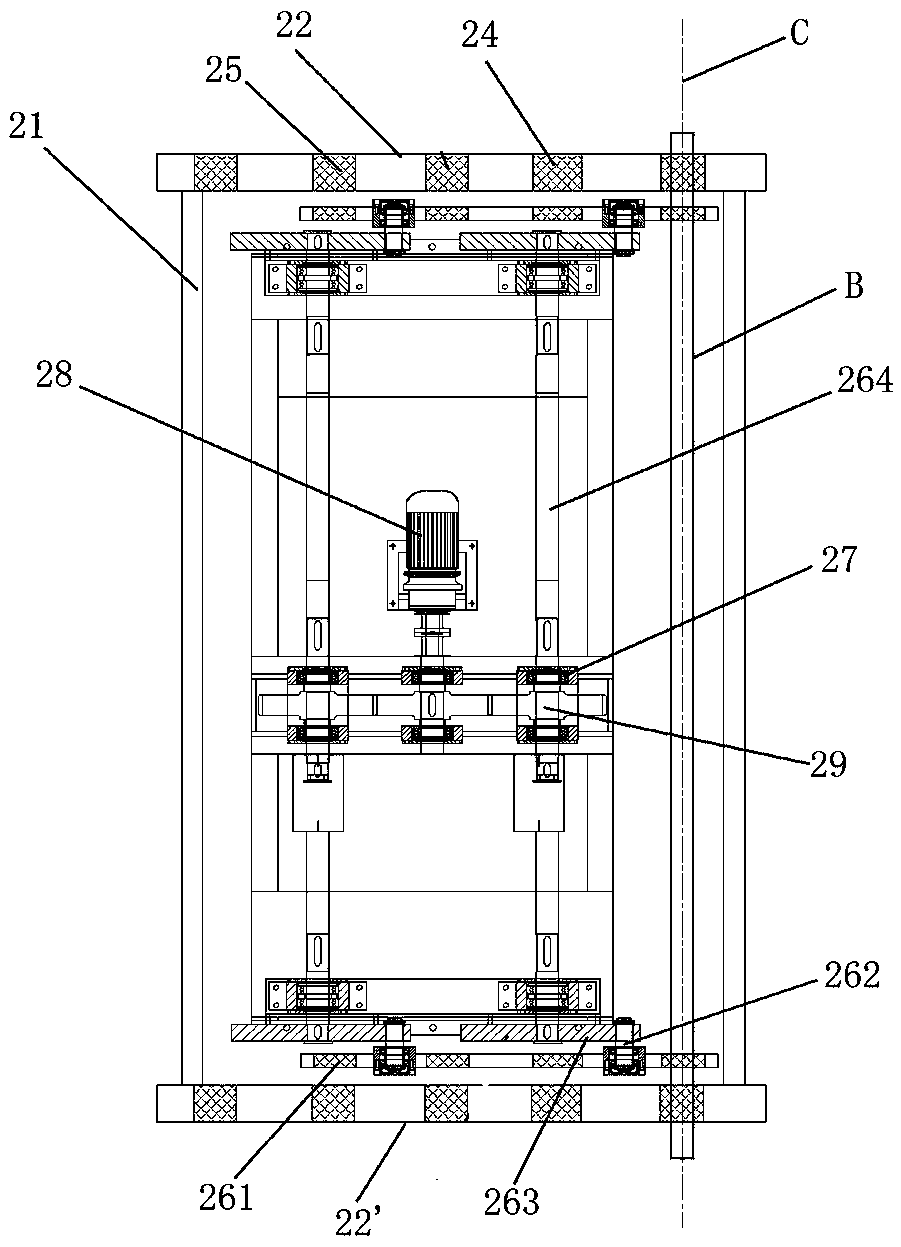

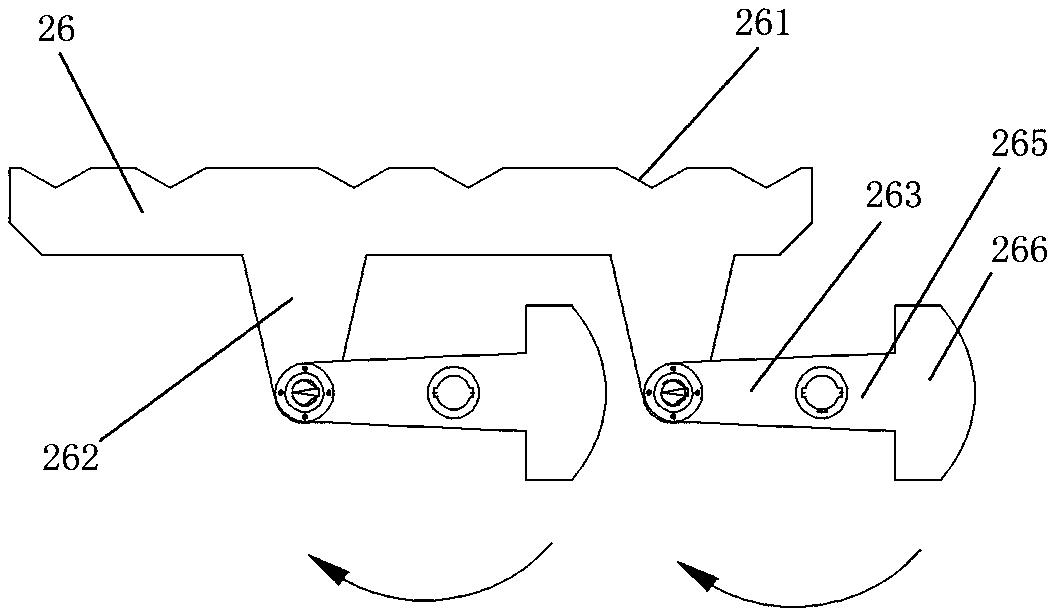

[0032] Such as figure 1 Shown is a structural schematic diagram of a multi-station continuous processing production line for steel pipes after hot-dip galvanizing provided by the present invention. The structure constituting the multi-station continuous processing production line is mainly composed of a hot-dip galvanized steel pipe B connected to the zinc pot A for longitudinal movement, separated from the upward track 1 of the zinc pot A, and a progressive conveying device 2 connected to the upward track 1. The down track 3 at the end of the progressive conveying device 2 is composed of a water cooling device 4 connected to the down track 3, wherein the up track 1 is provided with a hot-dip galvanized steel pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com