Vacuum cathode arc coating machine for large tank inner wall coating

A technology in the coating machine and tank body, which is applied in the field of vacuum cathode arc coating machine, can solve the problems that the coating machine cannot be realized, and achieve the effect of solving the problem of vacuum coating, saving cost and reducing the arrangement density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

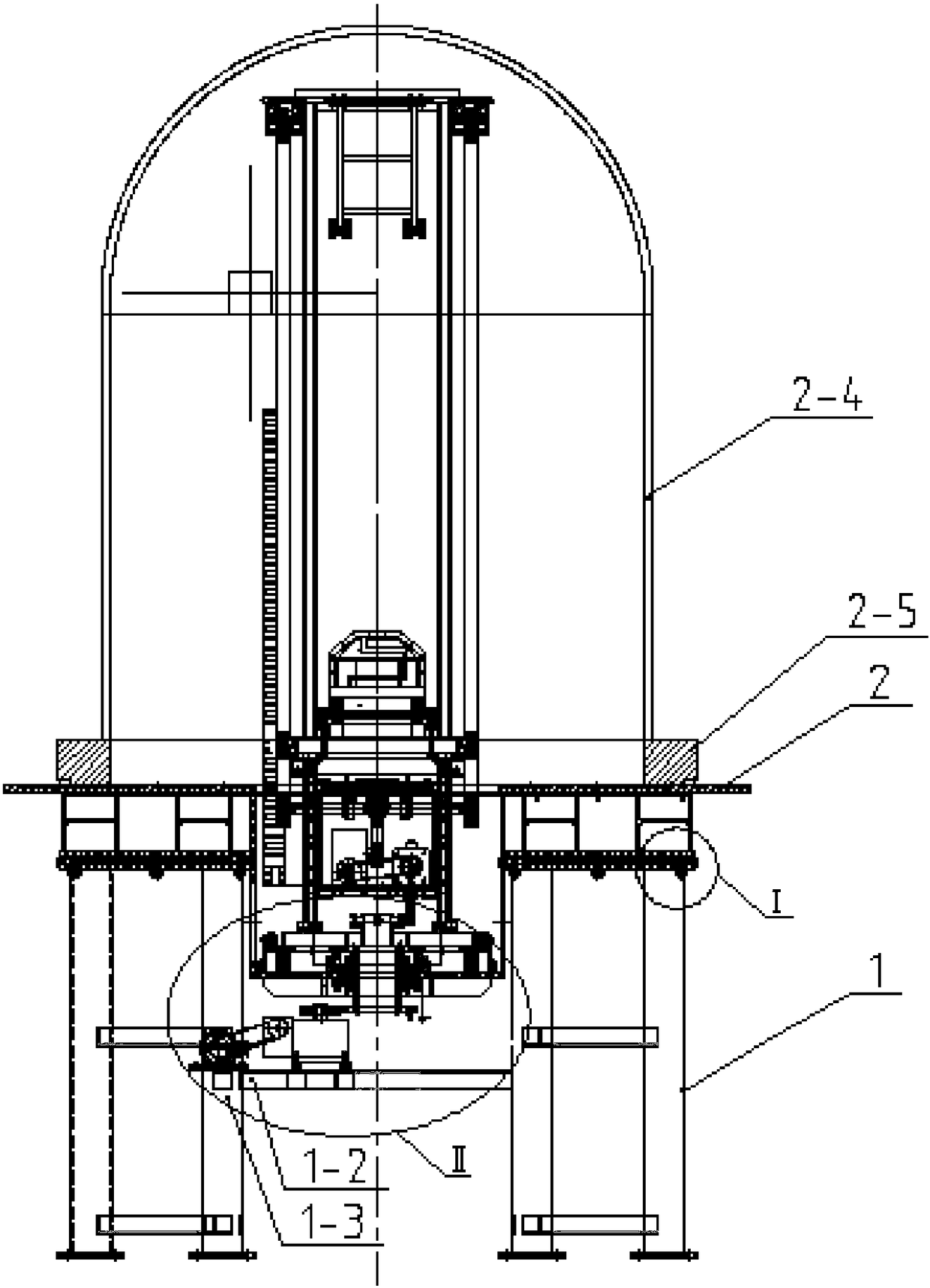

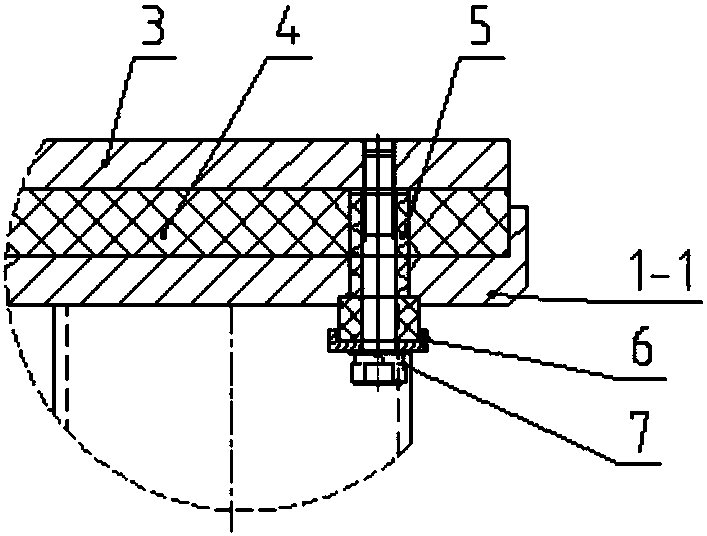

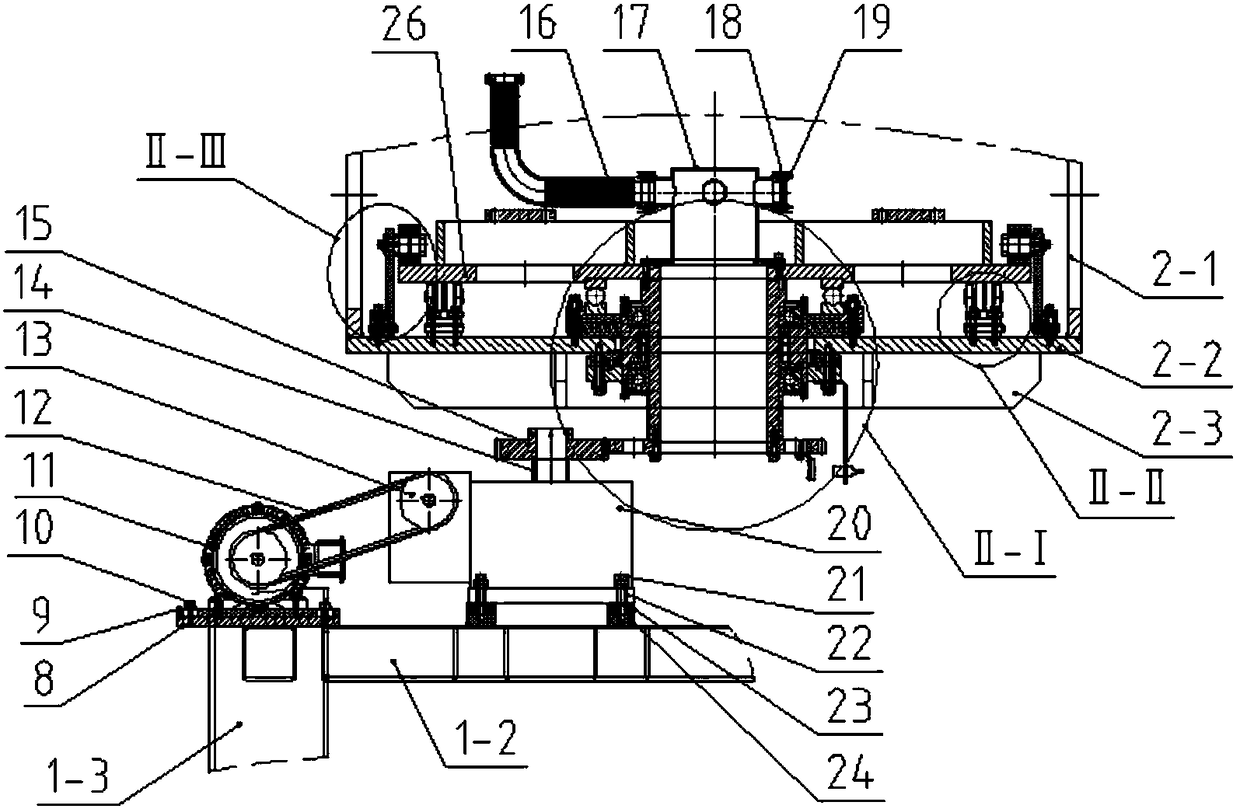

[0046] figure 1 It is the front view of the coating machine, showing the main structure of the coating machine. The frame 1 supports the main body of the coating machine, the furnace platform 2 belongs to the chassis of the vacuum furnace, and the workpiece to be plated is a chemical tank 2-4, which is a large cylindrical tank with a convex arc-shaped top cover. It is buckled upside down on the furnace body platform 2, and the position of the furnace body platform 2 corresponding to the opening edge of the chemical tank 2-4 is provided with a vacuum sealing groove and an O-shaped sealing ring. The chemical tank 2-4 becomes the furnace wall of the furnace body, and the ion plating The coating is just plated on the chemical tank 2-4 inner wall. In order to adapt to the coating of chemical tanks 2-4 with different diameters, the furnace platform 2 is provided with sealing grooves and O-rings of different diameters; Additional flanges 2-5 with sealing rings of different heights ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com