Full-function unattended-operation remote monitoring vaporization pressure-regulating system

A remote monitoring and pressure regulating system technology, applied in the direction of pressure vessels, equipment discharged from pressure vessels, fluid treatment accessories, etc., can solve the problems of a large number of LNG gasification stations, a large number of manpower and material resources, etc., to improve safety and Efficiency, reduction of energy consumption, and the effect of reducing production labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

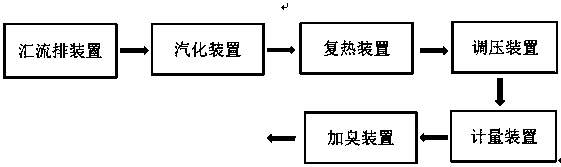

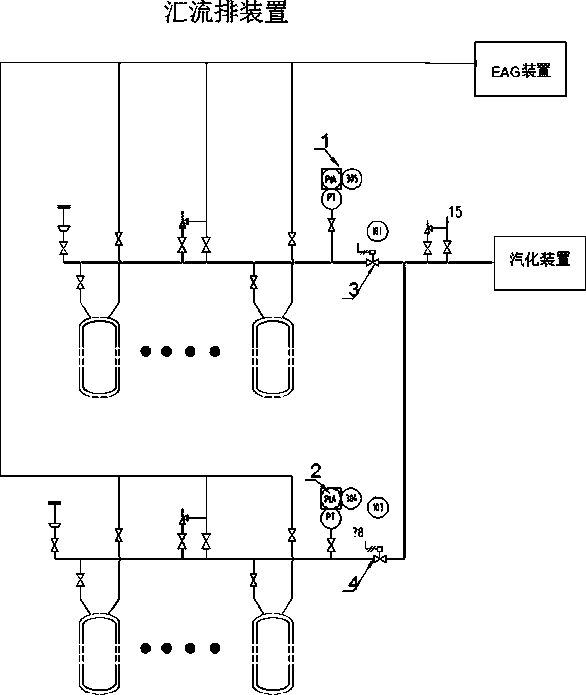

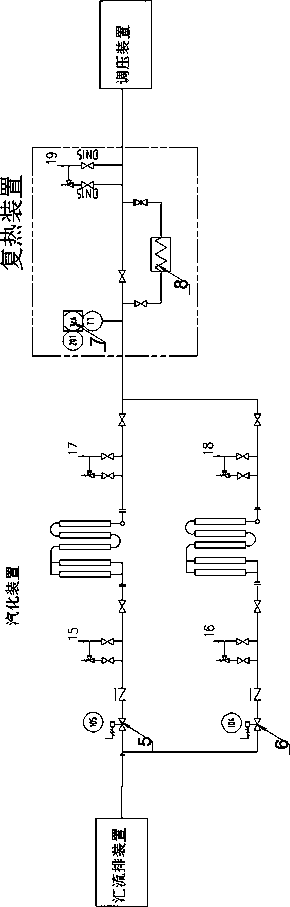

[0039] like Figure 1-5As shown, the full-featured unattended remote monitoring vaporization and pressure regulating system is characterized in that the liquefied natural gas in the cylinder is transported to the vaporization device through the busbar device for vaporization, then enters the reheating device, and then passes through the two-stage pressure regulating device After the pressure is adjusted, the pressure is reduced, and finally sent to the end customer through the metering device and the odorizing device; the busbar device includes two sets of busbars, intelligent pressure transmitters 1 and 2, low-temperature emergency shut-off valves 3 and 4, and each An intelligent pressure transmitter and a low-temperature emergency shut-off valve are installed on one set of bus bars; Cut-off valve; the reheating device includes an intelligent temperature transmitter 7, an intelligent electric heater 8, and an intelligent pressure transmitter 9. The temperature of the vaporize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com