Compact-type precise piezoelectric stick-slip lifting platform and driving method thereof

A lifting platform, compact technology, applied in the field of compact precision piezoelectric stick-slip lifting platform and its drive, can solve the problems of harsh working environment, limited working stroke, low positioning accuracy, etc., to improve mechanical output characteristics, The effect of reducing frictional resistance and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

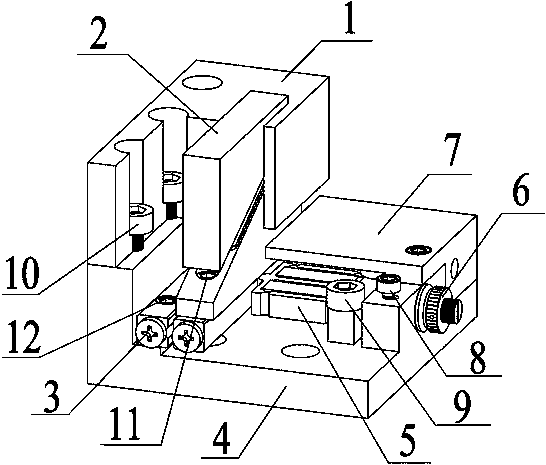

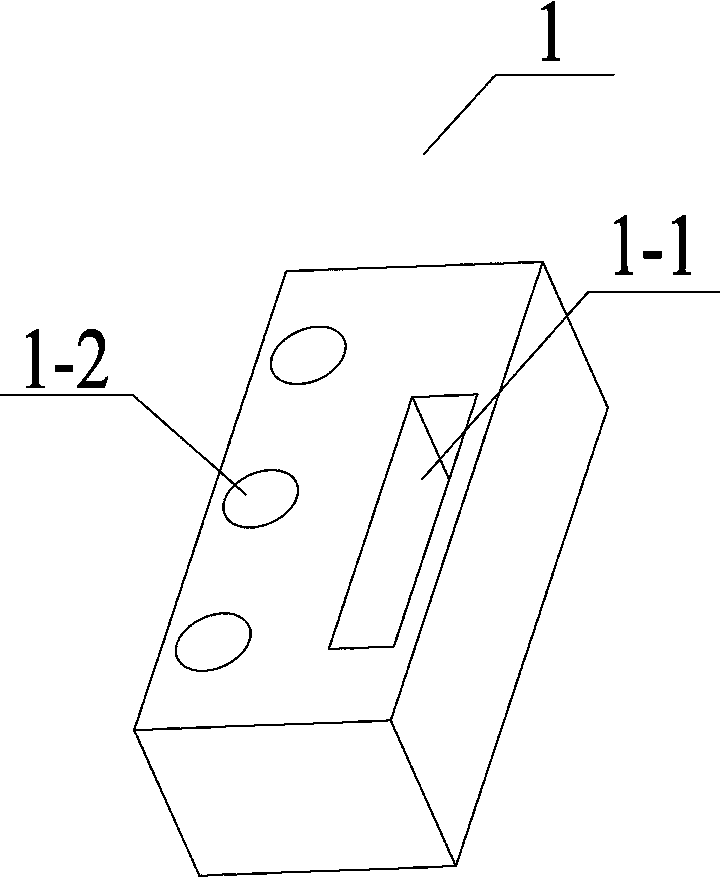

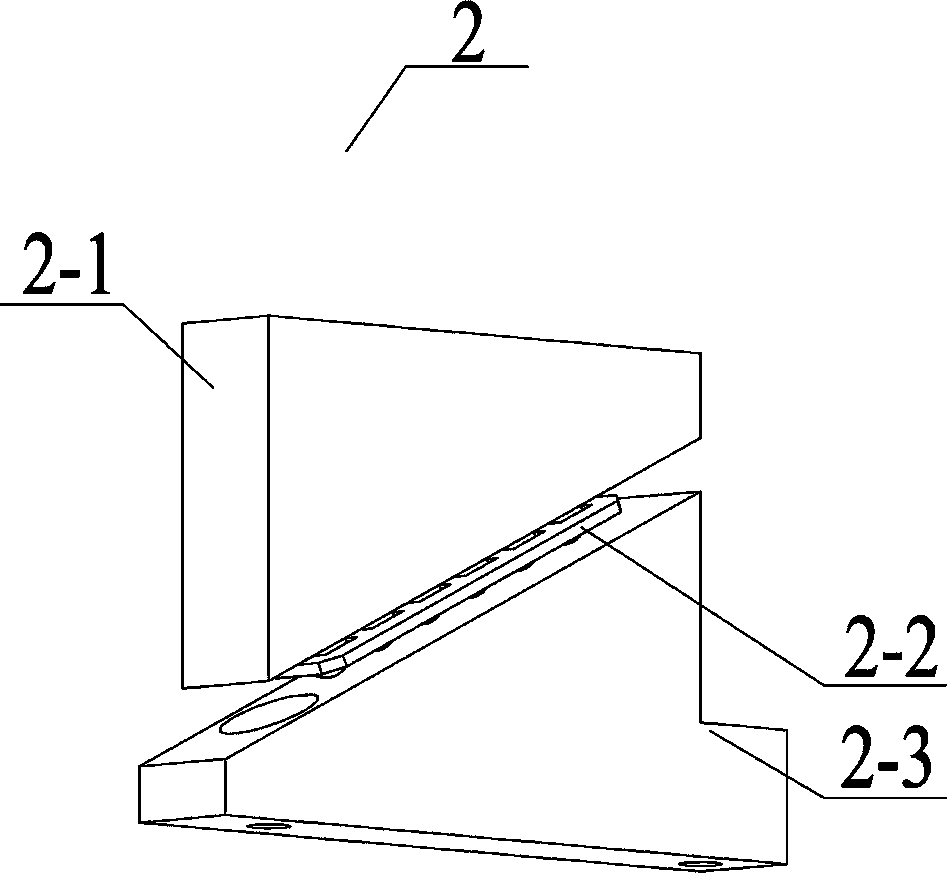

[0041] Specific implementation mode one: combine Figure 1~Figure 10 This embodiment will be described. This implementation mode provides a specific implementation scheme of a compact precision piezoelectric stick-slip lifting platform that realizes double-stacked single-drive foot stator assemblies. The compact precision piezoelectric stick-slip elevating platform of the double-stacked single-drive foot stator assembly includes a limit table 1, a displacement table 2, a double row cross roller guide rail 3, a fixed base 4, a drive stator 5, Thread pair 6, end cover 7, end cover mounting screws 8, stator mounting screws 9, limit table screws 10, displacement table screws 11 and guide rail mounting bolts 12; the limit table 1 is installed on the fixed On the base 4, the displacement stage 2 is installed and fixed on the double row cross roller guide rail 3 through the displacement stage screw 11, the double row cross roller guide rail 3 is installed on the fixed base 4 through...

specific Embodiment approach 2

[0048] Specific implementation mode two: combination Figure 11~Figure 12 This embodiment will be described. This embodiment provides a compact and precise piezoelectric stick-slip lifting platform realized by a diamond-shaped stator assembly. Its structural composition and connection method are the same as those in the first embodiment, except that the specific structure of the flexible hinge mechanism 5-1 in the driving stator 5 is different.

[0049] The flexible hinge mechanism 5-1 is made of 5052, 6061 or 7075 aluminum alloy material, and the flexible hinge mechanism 5-1 adopts an asymmetric rhombic structure hinge. The flexible hinge mechanism 5-1 is provided with a driving foot 5-1-1, an end beam 5-1-3, a stator mounting hole 5-1-4, a base screw mounting hole 5-1-6, a rigid folding beam Ⅰ 5-1-20, rigid polybeam Ⅱ 5-1-21, rigid polybeam Ⅲ 5-1-22, rigid polybeam Ⅳ 5-1-23, straight round hinge Ⅷ 5-1-24, straight round Hinge VII 5-1-25, straight round hinge X5-1-26 and s...

specific Embodiment approach 3

[0050] Specific implementation mode three: combination Figure 13~Figure 14 This embodiment will be described. This embodiment provides a compact precision piezoelectric stick-slip lifting platform realized by an inclined ladder stator assembly. Its structural composition and connection method are the same as those in the first embodiment, except that the specific structure of the flexible hinge mechanism 5-1 in the driving stator 5 is different.

[0051] The flexible hinge mechanism 5-1 adopts a flexible hinge with an inclined ladder frame structure, and the flexible hinge mechanism 5-1 adopts 5052 aluminum alloy, 6061 aluminum alloy, 7075 aluminum alloy, Ti-35A titanium alloy or Ti-13 titanium Alloy materials. The flexible hinge mechanism 5-1 is provided with a stator mounting hole 5-1-4, and the flexible hinge mechanism 5-1 is fixed with the stator mounting threaded hole 4-6 through the stator mounting screw 9; the flexible hinge mechanism 5-1 is provided with There are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com