New energy automobile lithium battery counter electrode processing equipment with automated processing and placing function

A technology for new energy vehicles and processing equipment, applied in metal processing equipment, grinding drives, grinding/polishing equipment, etc., can solve the problems of low work efficiency, complicated operation, incomplete plates, etc., and reduce labor intensity. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

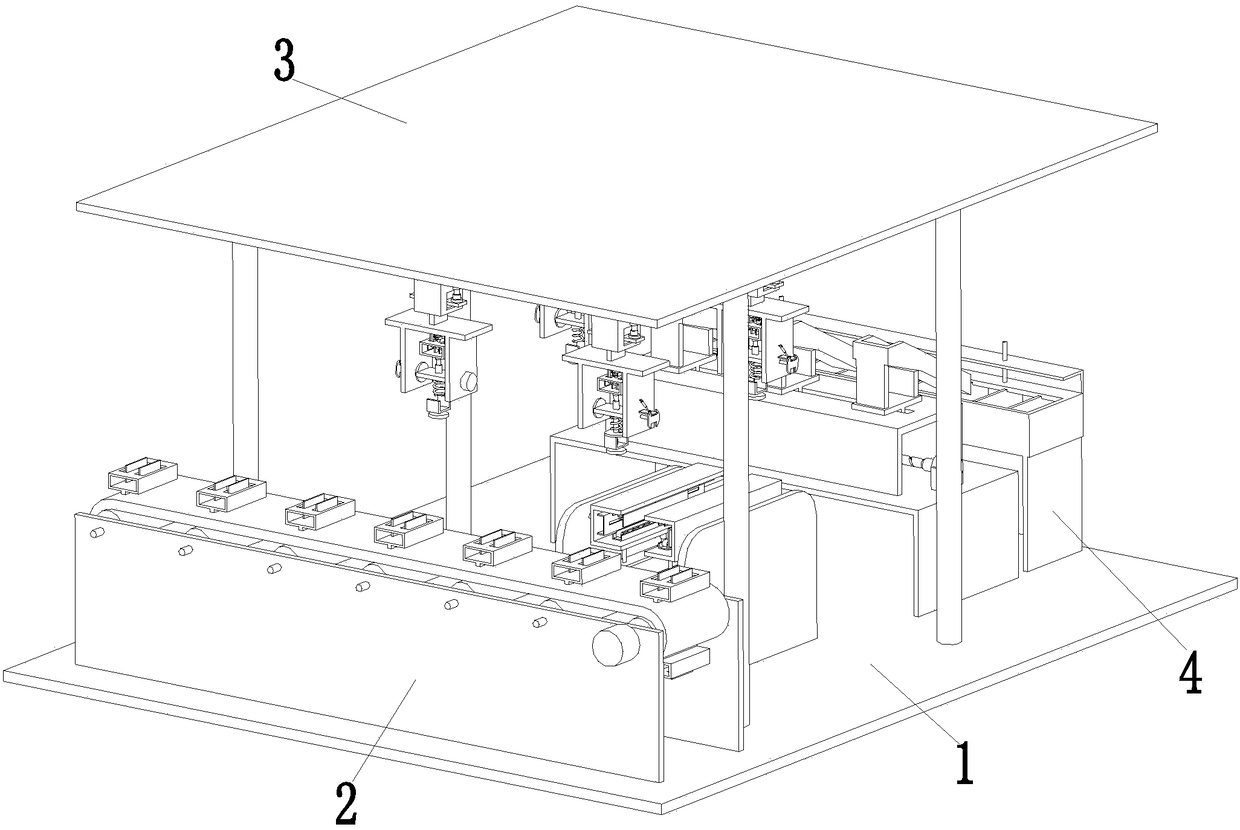

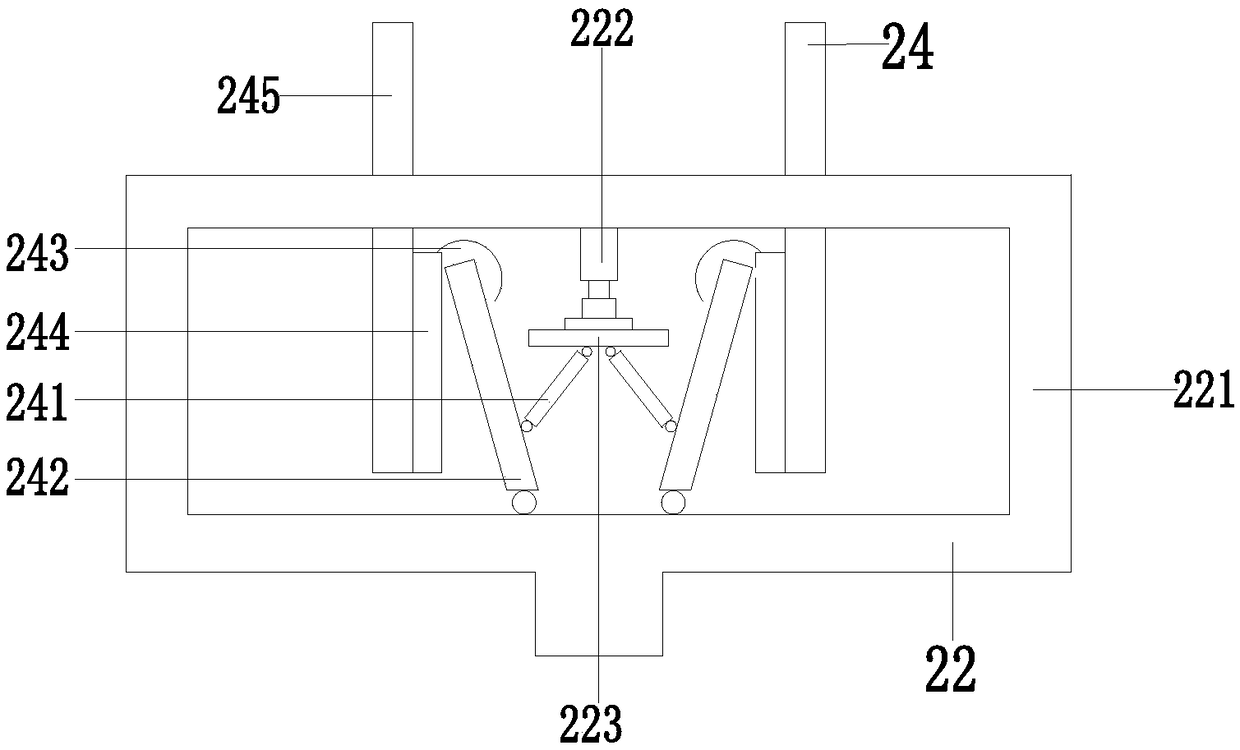

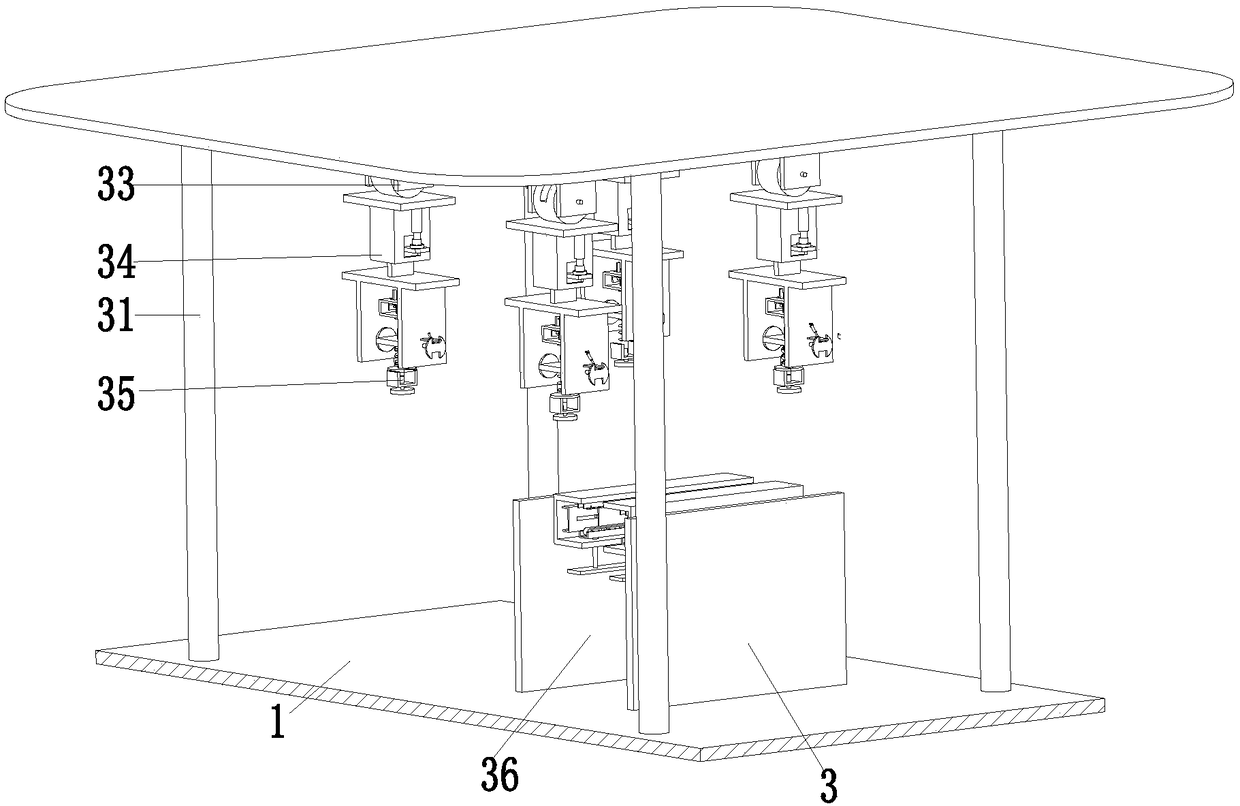

[0033] like Figure 1 to Figure 9 As shown, a new energy vehicle lithium battery plate processing equipment that can be automatically processed and placed includes a bottom plate 1, on which a stable feeding device 2, a grinding and conveying device 3 and a separate storage device 4 are installed in sequence from front to back, stable The feeding device 2 can stably transport the pole plate to the designated working position, the grinding and conveying device 3 can transport the pole plate, and can polish the pole plate during the conveying process, and the separated storage device 4 can clean the pole plate after processing The plates are temporarily stored separately to avoid collisions between the plates and affect the use of the plates. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com