Off-line coating feeding system

A feeding system and coating technology, applied in filament forming treatment, feeding solution to spinneret, spinning solution filtration, etc., can solve problems such as unstable pressure control, complex structure, and coating quality cannot be effectively guaranteed , to achieve the effect of ensuring the purity and quality of the optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

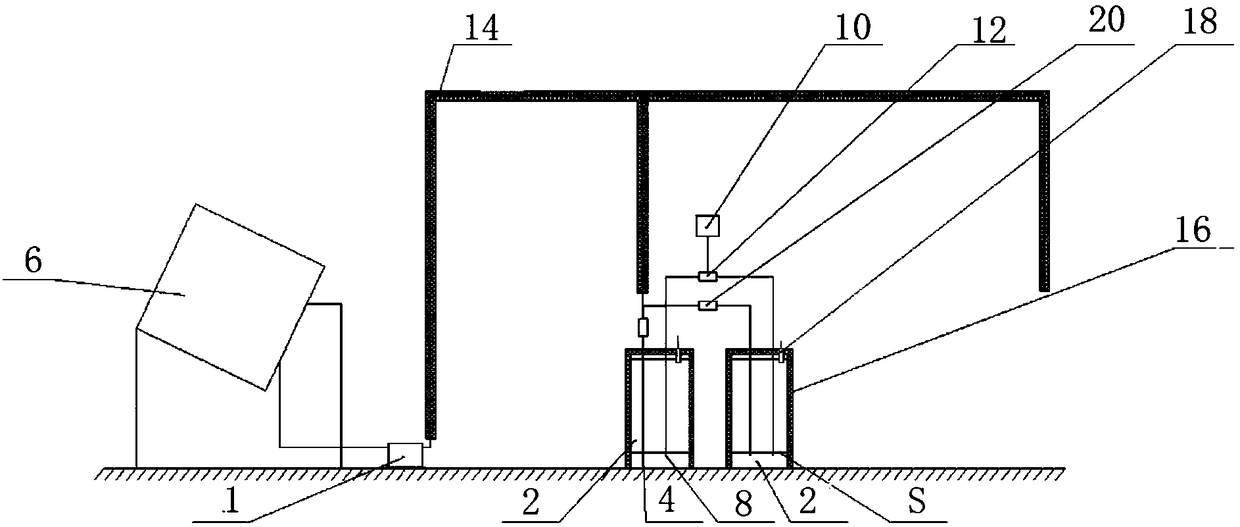

[0022] like figure 1 As shown, this embodiment discloses a paint off-line feeding system, including a paint tank group and a heating assembly, the above-mentioned paint tank group has at least two paint tanks 2, and each of the above-mentioned paint tanks 2 passes through a feed pipe 4 with a pump Connect the paint storage tank 6, each of the above-mentioned paint tanks 2 is connected to the coating die base 10 through the discharge pipe 8, and the above-mentioned paint tank 2, one of which is selected by the feed switching unit 12, is supplied to the coating die base 10; The heating assembly heats the paint storage tank 6, the feed pipe 4, the discharge pipe 8 and each paint tank 2 respectively.

[0023] An optical fiber drawing production line is equipped with a feed system in this embodiment, and the paint stored in the ton-level paint storage tank 6 is sucked into each paint tank 2, and is selected by the feed switching unit 12 in each paint tank 2. One of the paint tanks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com