High pressure grouting construction method using steel structure and CGM materials

A high-pressure grouting and construction method technology, which is applied in the processing of building materials, building construction, construction, etc., can solve the problems of large personnel investment, low construction efficiency, and large reserved holes, and achieves a high degree of mechanization and construction safety. High, good construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

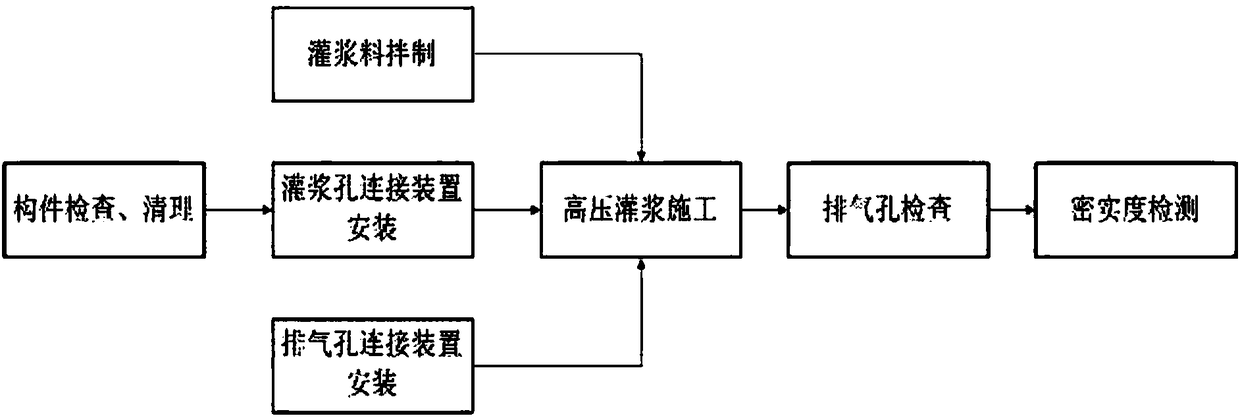

[0019] see figure 1 , a high-pressure grouting construction method using steel structures and CGM materials, the specific steps are as follows:

[0020] Step 1, mixing the grouting material: Mix the CGM grouting material and drinking water at 5-40 degrees Celsius according to the mass ratio of 18-20:100 for manual or mechanical mixing. The time for mechanical mixing is 1-2 minutes. First add 2 / 3 of the total amount of drinking water and stir for 2 minutes, then add the remaining drinking water and stir well. The total time of manual mixing should not exceed 5 minutes. Use a forced mixer for mechanical mixing to ensure sufficient and even mixing. The mixing time is 3-5 minutes. The fluidity of the stirred grouting material will decrease with the increase of the parking time. It should be used up within 40 minutes. It is strictly forbidden to mix an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com