Method for evaluating recrystallization tendency of single-crystal superalloy

A technology of superalloys and evaluation methods, applied in the field of superalloys, which can solve the problems of large differences in size and size, inability to reflect influence, and inability to use quantitative standards for recrystallization tendency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

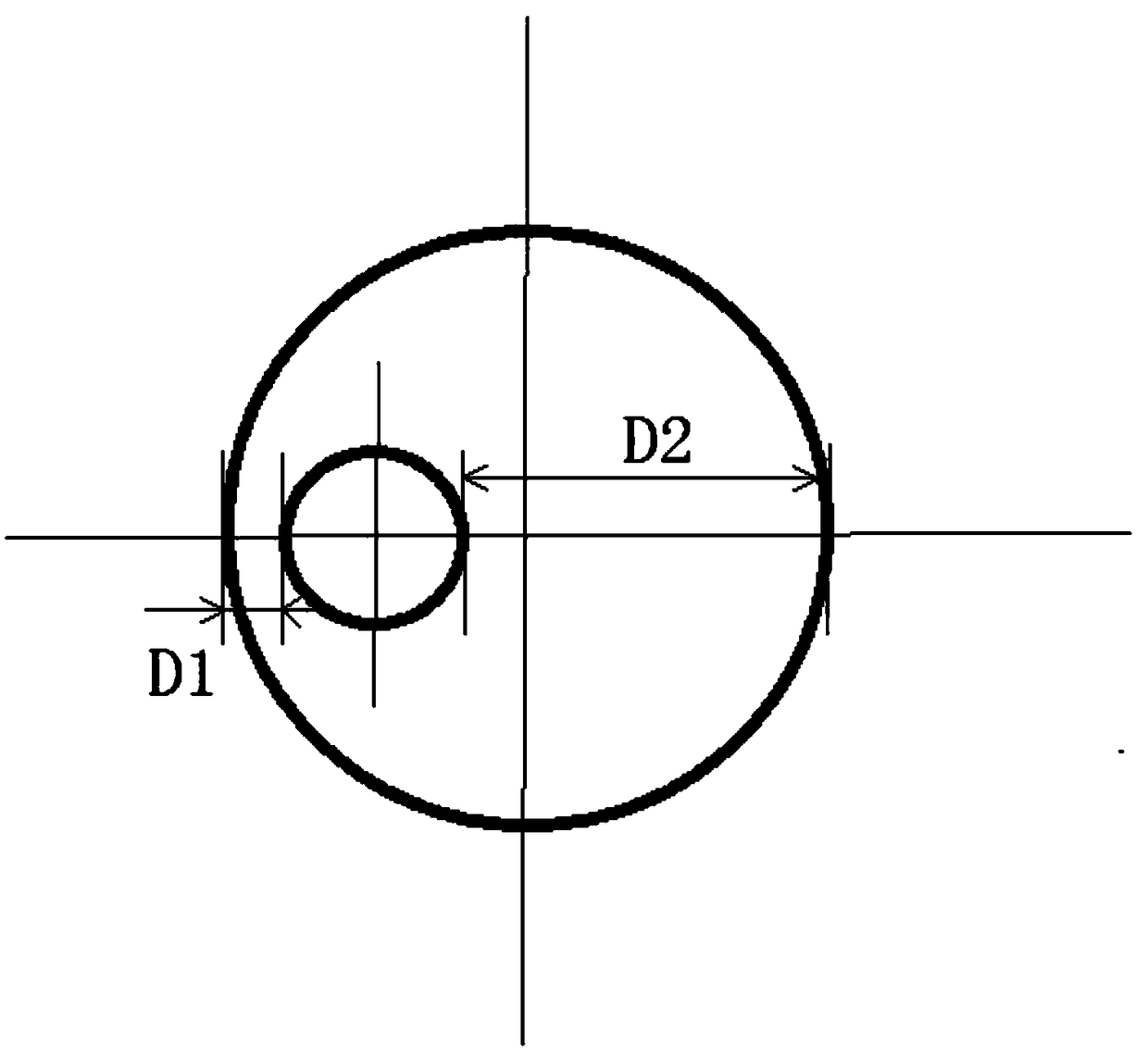

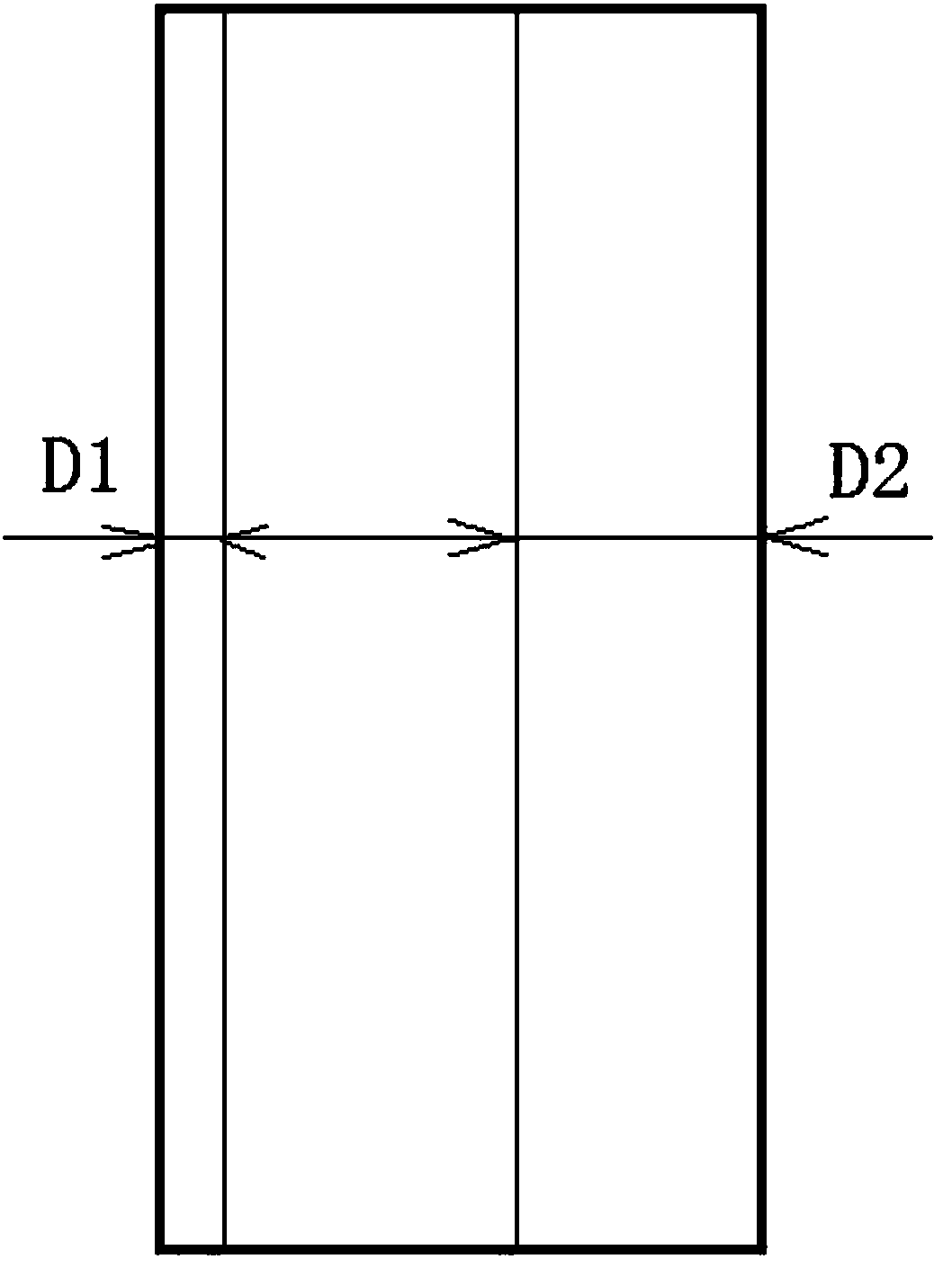

[0021] First prepare the eccentric tubular sample of PWA1483 single crystal material, the height of the tubular sample is 300 mm, the outer diameter is 20 mm, the thickness of the thin wall is D1: the thickness of the thick wall is D2 = 1:20; the wax mold of the tubular sample is formed The pressure is 0.3MPa, the wax temperature is 68°C, and the holding time is 10 seconds; the mold shell of the tubular sample is prepared by alumina coating and alumina shell material; the pouring temperature for preparing the single crystal eccentric tubular sample is 1550°C , The solidification pulling speed is 3mm / min; after the tubular sample is prepared, the standard heat treatment is carried out, and then the macroscopic corrosion is carried out, and no recrystallization is observed at the thin wall.

Embodiment 2

[0023] First prepare the eccentric tubular sample of PWA1484 single crystal material, the height of the tubular sample is 300 mm, the outer diameter is 20 mm, the thickness of the thin wall is D1: the thickness of the thick wall is D2 = 1:20; the wax mold of the tubular sample is formed The pressure is 0.3MPa, the wax temperature is 68°C, and the holding time is 10 seconds; the mold shell of the tubular sample is prepared by alumina coating and alumina shell material; the pouring temperature for preparing the single crystal eccentric tubular sample is 1550°C , the solidification pulling speed is 3mm / min; after the tubular sample is prepared, the standard heat treatment is carried out, and then the macroscopic corrosion is carried out, and recrystallization is observed at the thin wall. By calculation, the ratio of the area of recrystallized grains in the cross-section of the sample to the area of the cross-section of the tubular sample is 1.5%.

Embodiment 3

[0025] First prepare the eccentric tubular sample of CMSX-4 alloy single crystal material, the height of the tubular sample is 100 mm, the outer diameter is 10 mm, the thickness of thin wall D1: the thickness of thick wall D2 = 1:15; the tubular sample The wax mold molding pressure is 0.2MPa, the wax temperature is 69°C, and the holding time is 60 seconds; the mold shell of the tubular sample is prepared by alumina coating and alumina shell material; the pouring temperature for preparing the single crystal tubular sample is 1480°C, the solidification rate is 9mm / min; after the tubular sample is prepared, the standard heat treatment is carried out, and then the macroscopic corrosion is carried out, and no recrystallization is observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com