Mechanical polishing solution for preparing EBSD sample, preparation method and mechanical polishing method

A technology of mechanical polishing and polishing liquid, which is applied in the preparation of test samples, polishing compositions containing abrasives, etc., can solve the problems of complicated preparation process, long time consumption, low calibration rate, etc., and achieves simple operation and short time consumption. , the effect of high calibration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

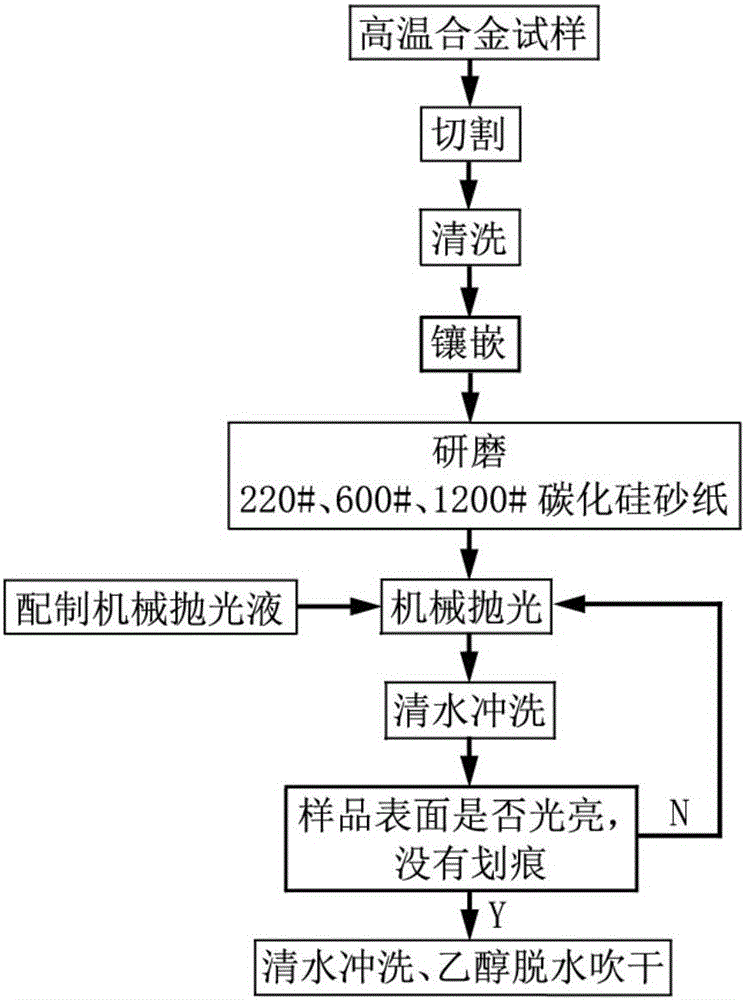

[0056] Experimental alloy DD407, as per figure 1 The sequence of procedures shown is for mechanical polishing of the samples.

[0057] (1) Cutting: cutting DD407 samples by wire cutting method;

[0058] In this embodiment, the nickel-based single crystal superalloy DD407 to be cut is fixed on a wire cutting machine, and cut along the section to be analyzed. The thickness of the DD407 sample is 5-6 mm.

[0059] (2) Cleaning: Use acetone to clean the DD407 sample cut in step (1) to remove the oil or other pollutants remaining on the surface of the sample during the cutting process of the DD407 sample, then rinse with water, dehydrate and dry with ethanol;

[0060] In this embodiment, when using acetone to clean the cut DD407 sample, dip a clean brush into acetone to scrub the surface of the DD407 sample, and then rinse it with water.

[0061] (3) Mounting: The DD407 sample cleaned in step (2) was mounted using the hot-press mounting method, and the DD407 sample was placed in t...

Embodiment 3

[0076] Experimental alloy DD406, as per figure 1 The sequence of procedures shown is for mechanical polishing of the samples.

[0077] (1) Cutting: cutting DD406 samples by wire cutting method;

[0078] In this embodiment, the nickel-based single crystal superalloy DD406 to be cut is fixed on a wire cutting machine, and cut along the section to be analyzed. The thickness of the DD406 sample is 5-6 mm.

[0079] (2) Cleaning: Clean the DD406 sample cut in step (1) with acetone to remove the oil or other pollutants remaining on the surface of the sample during the cutting process of the DD406 sample, then rinse with water, dehydrate and dry with ethanol;

[0080] In this embodiment, when using acetone to clean the cut DD406 sample, use a clean brush dipped in acetone to scrub the surface of the DD406 sample, and then rinse it with water.

[0081] (3) Mounting: The DD406 sample cleaned in step (2) was mounted using the hot-press mounting method, and the DD406 sample was placed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com