Platinum group element reinforced high-thermal stability and high-strength nickel-based single-crystal high-temperature alloy

A high thermal stability, nickel-based single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of poor structure stability and low strength at high temperature, and achieve the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0057] See Table 1 for the chemical composition of the nickel-based single crystal superalloy in Examples 1-6 of the present invention.

[0058] Table 1 The chemical composition list (wt.%) of the alloy of the present invention (embodiment 1-6)

[0059] Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Cr 5.5 5.5 5 5 5 3.5 co 10 10 10 10 9 9 Mo 1.5 1.5 1.5 1.5 2 2.2 W 6 6 6 6 5.5 5.6 Al 6 6 6 6 5.6 6 Ta 8.5 8.5 8.5 8.5 8.5 7 Re 5.5 5.5 5.5 5.5 6 6 Ru 2.5 2.5 3 3 4 4.5 Ir 1.5 3 1.5 3 3 3 f 0.1 0.1 0.1 0.1 0.1 0.1 Y 0.02 0.02 0.02 0.02 0.02 0.02 Ni margin margin margin margin margin margin

[0060] Performance test is carried out to alloy in above embodiment, and result is as follows:

[0061] 1. The measured density of the alloy in Example 2 is 9.1g / cm 3 .

Embodiment 5

[0063] Table 2 Example 5 alloy durability

[0064]

[0065]

Embodiment 1

[0067] Table 3 Example 1 alloy tensile properties

[0068]

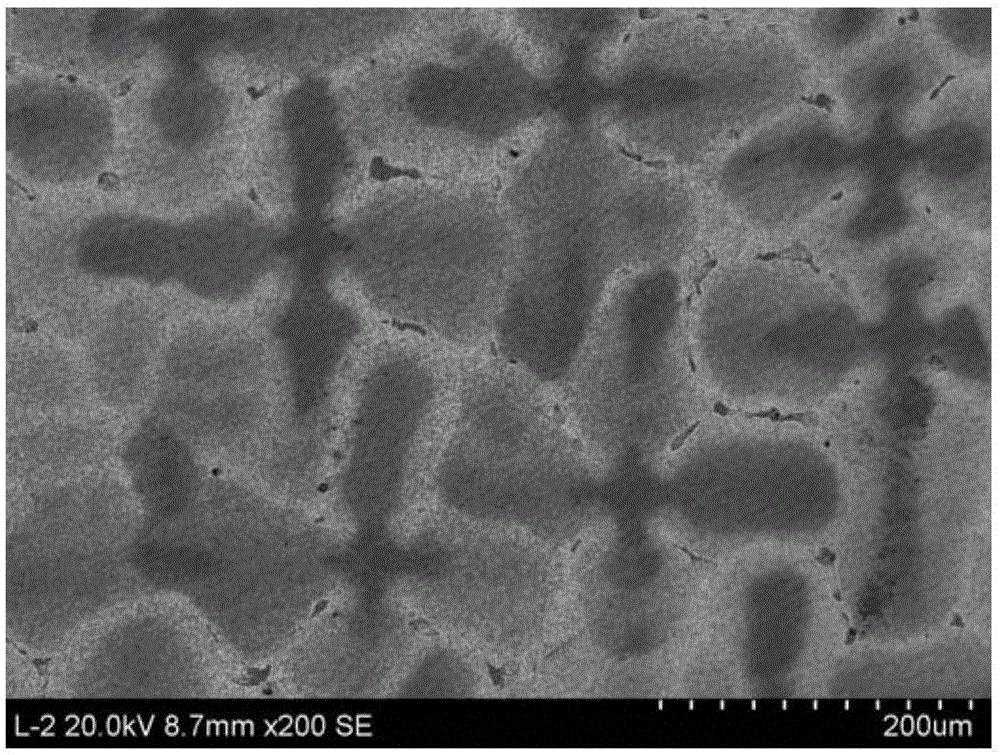

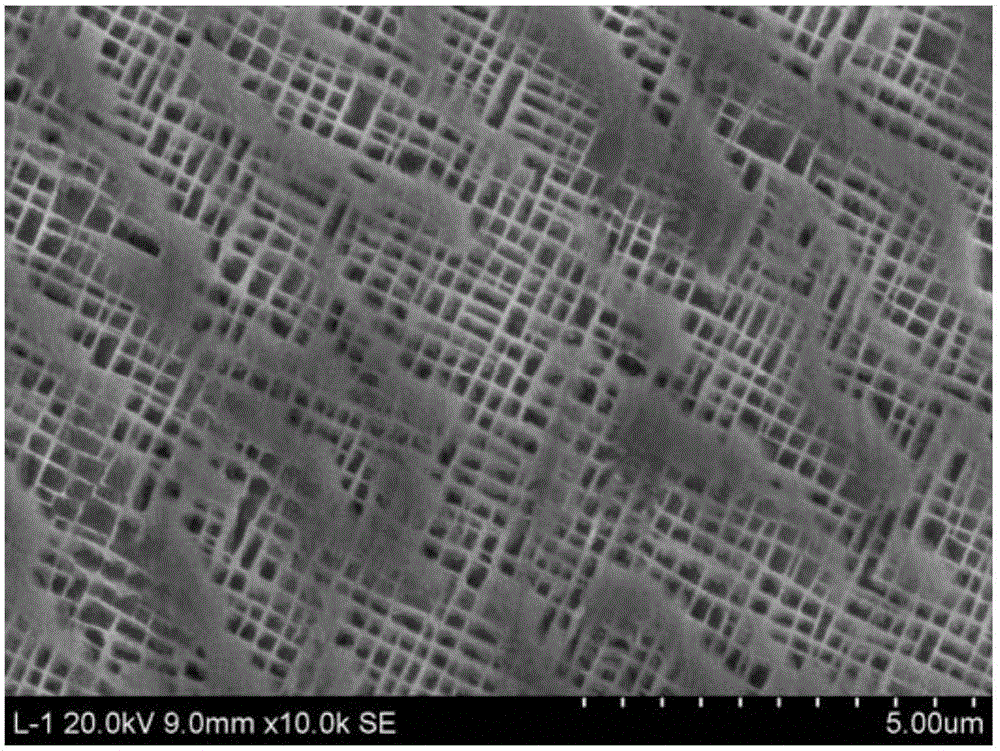

[0069] 4. The as-cast state of the alloy of Example 5 of the present invention and the microstructure after heat treatment such as figure 1 and figure 2 shown.

[0070] 5. The creep deformation curve of the alloy in Example 1 at 1100°C / 180MPa is as follows image 3 , the creep deformation curve of Example 2 at 1100°C / 180MPa is as follows Figure 4 , the increase of the Ir element content increases the creep life of the alloy; the creep deformation curve of the alloy in Example 5 at 1150°C / 137MPa is as follows Figure 5 , the coordinated effect of Ir and Ru elements leads to the improvement of the high temperature creep life of the alloy.

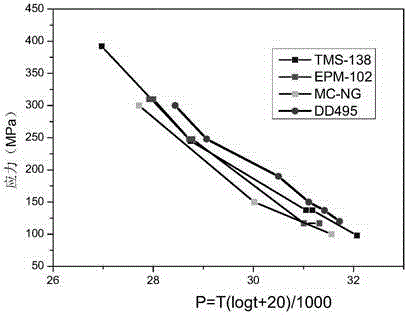

[0071] 6. Comparison of heat intensity curves between the alloy of Example 5 of the present invention and a typical fourth-generation single crystal superalloy Figure 6 , the strength of the alloy of the present invention is significantly higher than that of typical fourt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com