GaN-based vertical structure LED device

A technology of LED device and vertical structure, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of separation of metal substrate and GaN film, low production qualification rate, poor bonding force between GaN and single metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

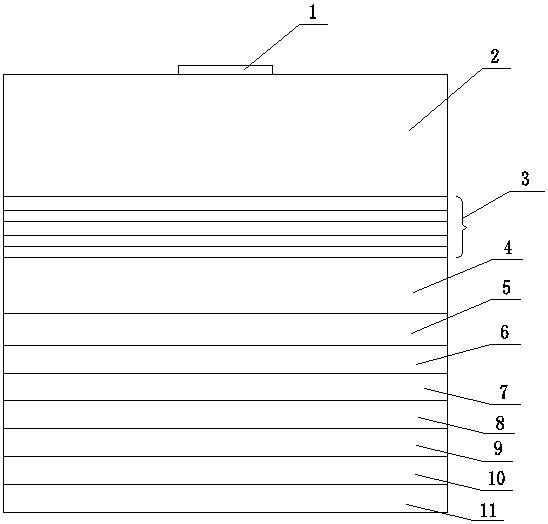

Examples

Embodiment 2

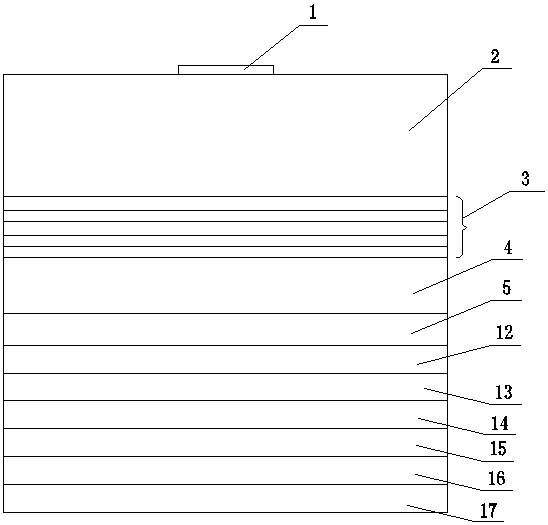

[0016] Such as figure 2 In the shown embodiment 2, this embodiment includes an N electrode 1, an N-type GaN layer 2, a GaN multi-quantum well active layer 3, a P-type GaN layer 4, a P electrode 5 and a metal substrate from top to bottom. Described metal substrate is by the cobalt layer 12 of 25 microns, the tungsten layer 13 of 15 microns, the cobalt layer 14 of 30 microns, the tungsten layer 15 of 40 microns, the cobalt layers 16 and 25 of 25 microns successively from the P electrode to the outside micron tungsten layer 30. The metal substrate has a strong bonding force with the P electrode, and obviously no longer warps.

Embodiment 3

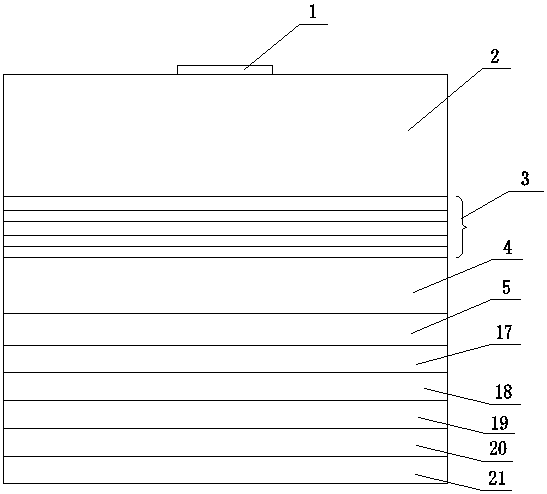

[0017] Such as image 3 In the illustrated embodiment 3, this embodiment includes an N electrode 1, an N-type GaN layer 2, a GaN multi-quantum well active layer 3, a P-type GaN layer 4, a P electrode 5 and a metal substrate from top to bottom. The metal substrate is sequentially composed of a palladium layer of 20 microns, a nickel layer of 18 microns, a palladium layer of 25 microns, a nickel layer of 30 microns, a palladium layer of 40 microns and a nickel layer of 38 microns from the P-GaN electrode to the outside. Layer 30 composition. The metal substrate has a strong bonding force with the P electrode, and obviously no longer warps.

Embodiment 4

[0018] Embodiment 4, this embodiment includes an N electrode 1, an N-type GaN layer 2, a GaN multi-quantum well active layer 3, a P-type GaN layer 4, a P electrode 5 and a metal substrate from top to bottom. The metal substrate is sequentially composed of a 23-micron gold layer, a 20-micron tungsten layer, a 35-micron gold layer, a 32-micron tungsten layer, a 38-micron gold layer and a 32-micron tungsten layer from the P-GaN electrode to the outside. Layer 30 composition. The metal substrate has a strong bonding force with the P electrode, and obviously no longer warps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com