Manufacturing method of bonding pad structure and manufacturing method of flip LED chip

An LED chip and manufacturing method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as tin diffusion, and achieve the effects of low cost, simple process, and convenience for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

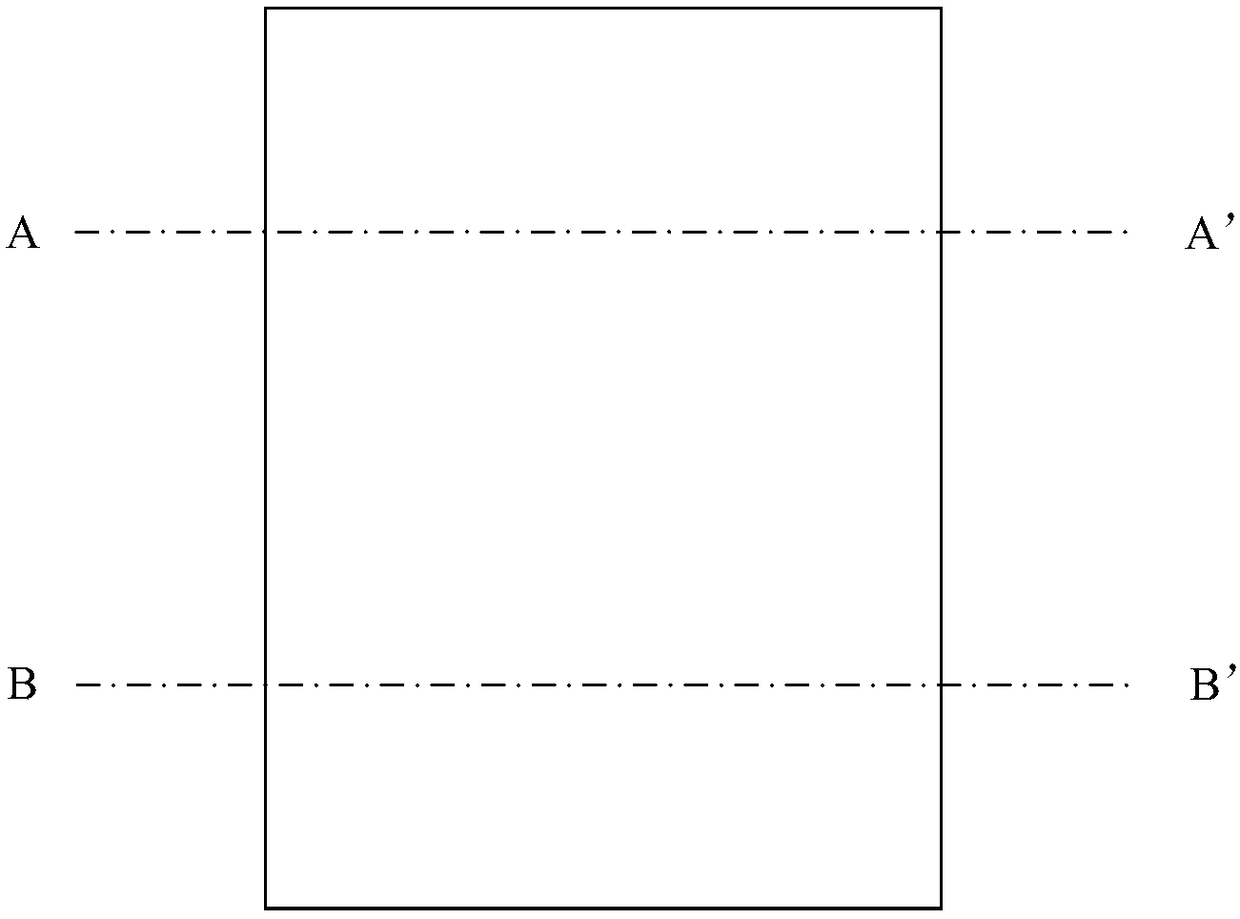

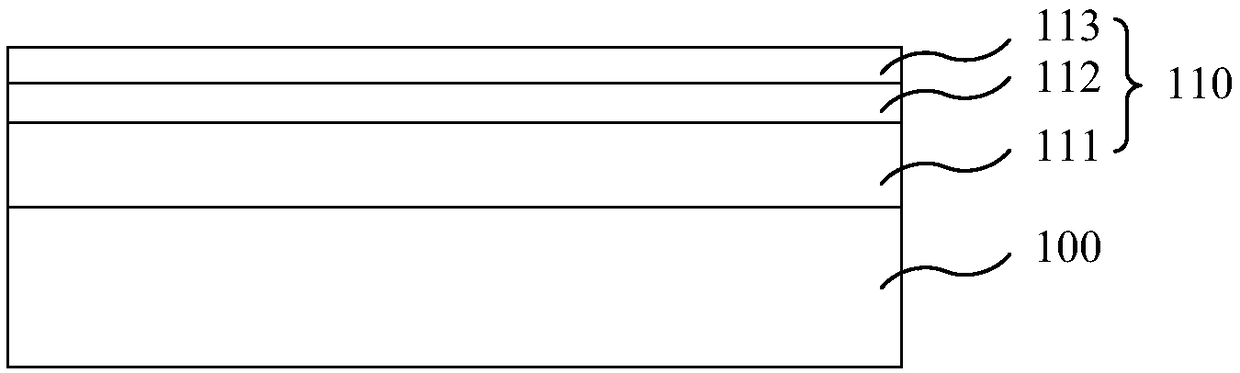

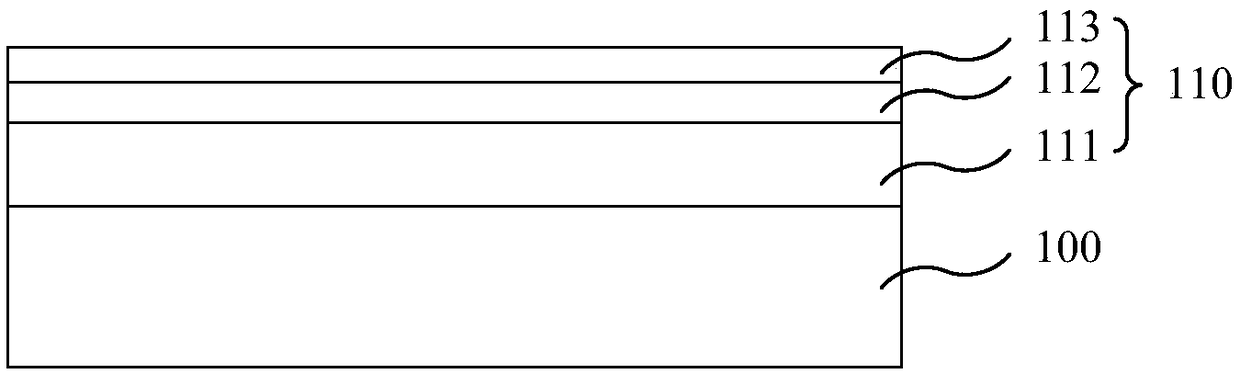

[0059] Such as Figure 1-18 As shown, the flip-chip LED chip includes: a substrate 100, an epitaxial layer 110, a current spreading layer 120, a first connecting electrode 131 and a second connecting electrode 132, an insulating reflective layer 140, a first bonding pad 151 and a second bonding pad. Disk 152.

[0060] The epitaxial layer 110 includes a first semiconductor layer 111, a light emitting layer 112, and a second semiconductor layer 113 formed in sequence, and at least one groove 110a is disposed on the epitaxial layer 110, and the depth of the groove 110a is greater than that of the light emitting layer. layer 112 and the thickness of the second semiconductor layer 113 is less than the thickness of the epitaxial layer 110, that is, the light emitting layer 112 and the second semiconductor layer 113 in the groove 110a are completely removed, while the first semiconductor layer 111 A part is removed, and the present invention does not limit the shape of the groove 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com