Fructus crataegi and white gourd fruit and vegetable juice beverage and preparation method thereof

A technology of wax gourd fruit and hawthorn is applied in the field of hawthorn wax gourd fruit and vegetable juice beverage, which can solve problems such as unreasonable process or formula, and achieve the effect of inhibiting blood sugar rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After washing the hawthorn fruit, blanch it with 80℃ water for 2 minutes, remove the core and stalk, weigh 1 part and beat with 3 times water; weigh 3 slices of winter melon meat, steam it in cage for 10 minutes, use 3 times pure water (can be reserved A small amount of additives is used) for beating, and the two pulps are combined. Add calcium chloride solution (0.3% of the total), protein sugar (100 times sweeter) (0.1% of the total), citric acid solution (0.1% of the total), mix, and fill at 60-65℃30 Sterilize in minutes.

Embodiment 2

[0027] After washing the hawthorn fruit, blanch it with 80℃ water for 2 minutes, remove the nucleus and stalks, weigh 2 portions and beat with 3 times water; weigh 2 portions of winter melon meat with 3 times water (a small amount of additives can be reserved) to beat, Mix the two syrups, add calcium chloride solution (0.3% of the total), protein sugar (100 times sweeter) solution (0.1% of the total), and citric acid solution (0.1% of the total) to mix, and fill 60 Sterilize at -65℃ for 30 minutes.

Embodiment 3

[0029] After washing the hawthorn fruit, blanch it with 80℃ water for 2 minutes, remove the pits and stalks, weigh 3 portions and beat with 3 times pure water. Weigh 1 portion of winter melon meat, cut into thick slices, steamed for 10 minutes, beaten with 3 times pure water (a small amount of additives can be reserved), and combine the two berries. Prepare the auxiliary agent with reserved water, add calcium chloride solution (0.3% of the total), protein sugar (100 times sweeter) solution (0.1% of the total), and citric acid solution (0.1% of the total) in sequence. Mix well, fill and sterilize at 60-65℃ for 30min.

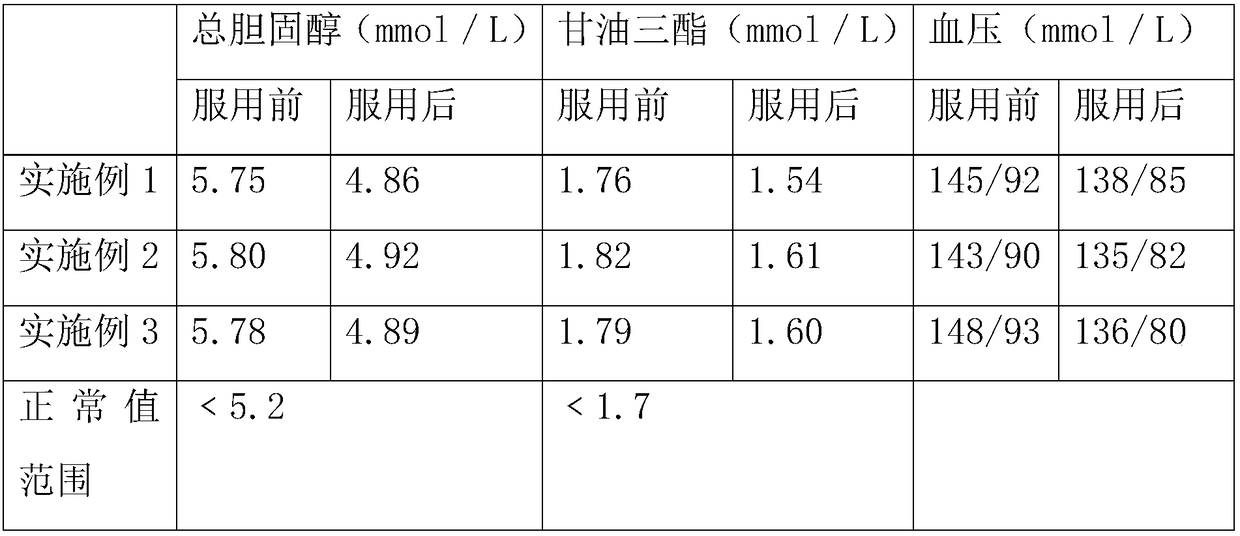

[0030] In the whole production process, the heating temperature and time of hawthorn are strictly controlled, and the active ingredients (lipase) for lowering lipids and hawthorn (antioxidant, anticancer) are retained to the greatest extent, supplemented by hawthorn. The stabilizer. The products obtained in the above examples were preserved, and there was no obvio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com