A kind of cobalt vanadate compound and its preparation method and application

A compound, cobalt vanadate technology, applied in cobalt compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of large capacity attenuation, large volume change, poor stability, etc., achieving easy materials, simple preparation methods, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

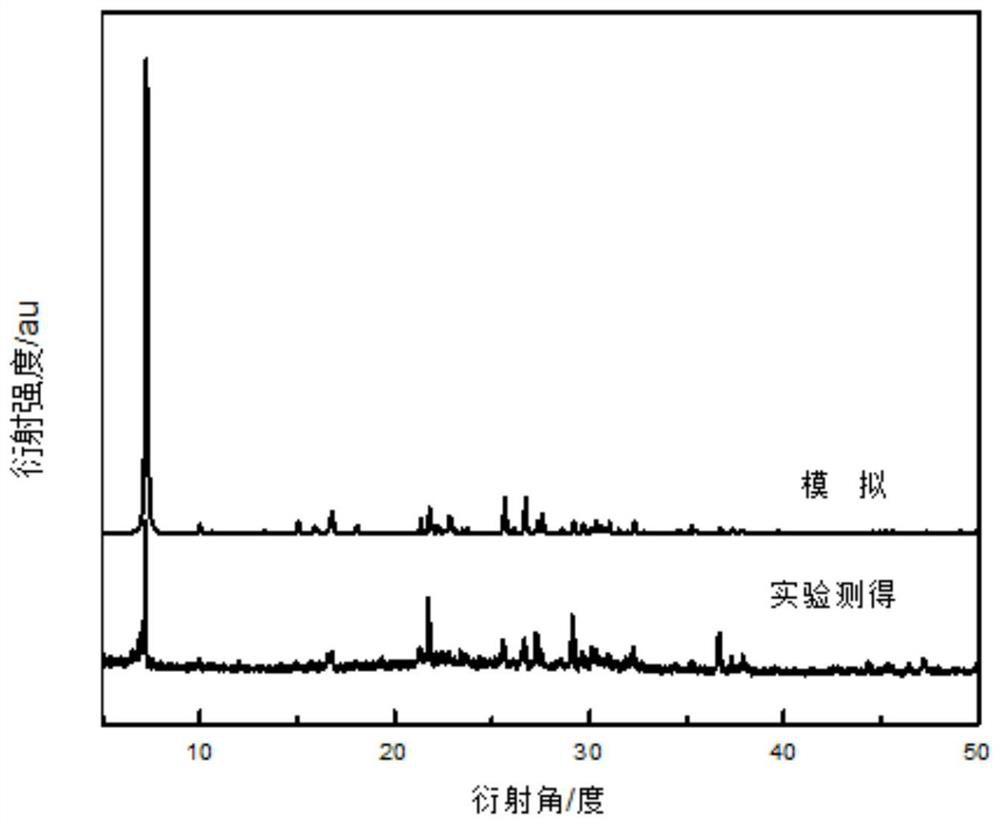

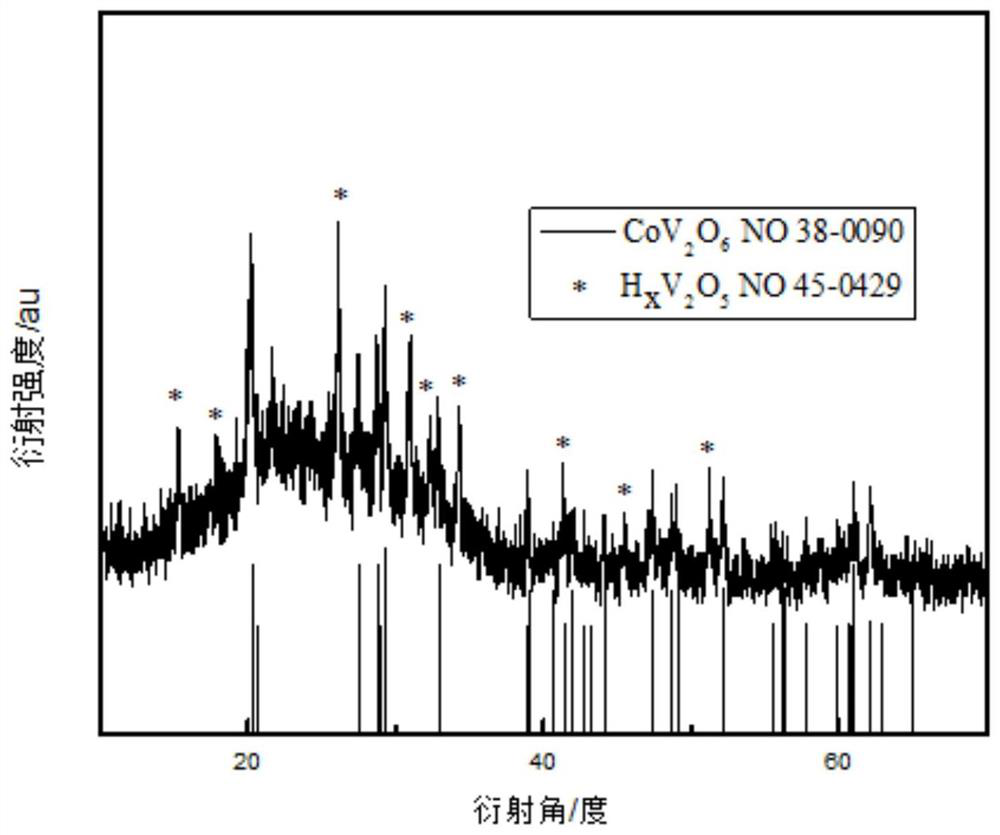

[0039] The preparation method of cobalt vanadate compound, comprises the steps:

[0040] (1) respectively take by weighing ammonium metavanadate 0.6mmol, hexahydrate cobalt nitrate 1.2mmol and 2,2-bipyridine 1.0mmol with purity greater than 99.9% for subsequent use;

[0041] (2) place the weighed cobalt nitrate hexahydrate in a beaker, add 5.5ml of deionized water and stir for 10 minutes to form a homogeneous solution, add the weighed 2,2-bipyridine and ammonium metavanadate and stir for 30 minutes, to obtain a mixed solution;

[0042] (3) 1.2 mmol H 3 BO 3 Add to the above mixed solution to adjust the pH to 4.5, then transfer the solution to a 15ml hydrothermal reactor and heat to 170°C for 72h;

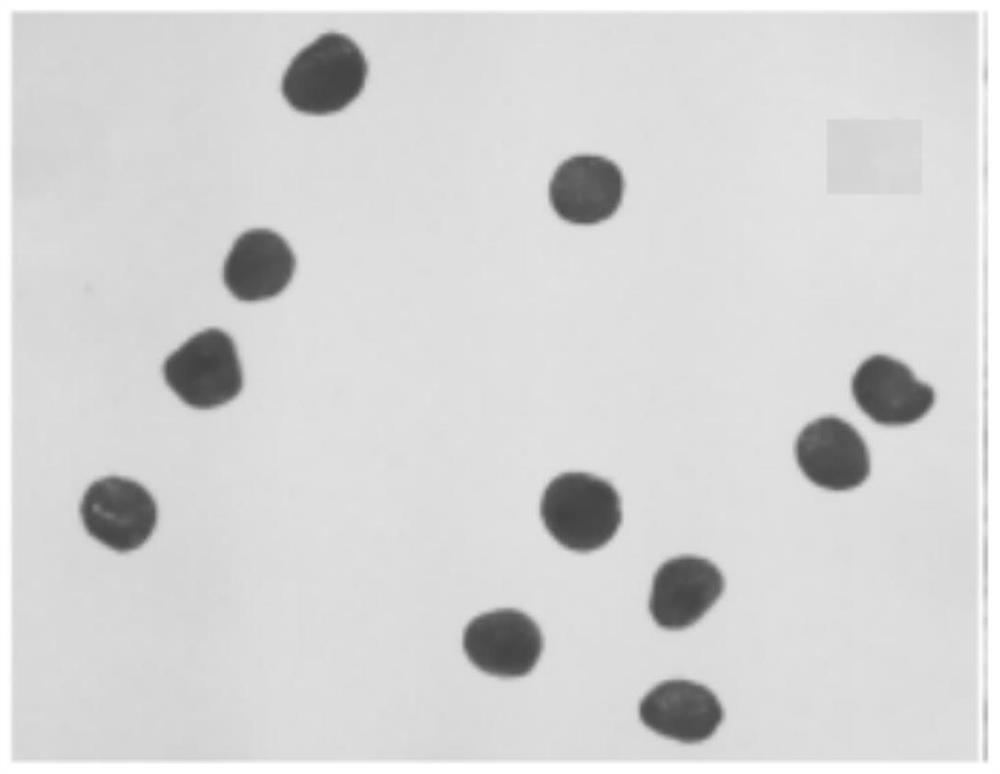

[0043] (4) cooling down to room temperature naturally, and then collecting after sonicating and drying at 80° C. for 12 hours to obtain the product;

[0044] (5) calcining the product at 600° C. for 4 hours in an air atmosphere with a heating rate of 2° C. / min to obtain the coba...

Embodiment 2

[0053] The preparation method of cobalt vanadate compound, comprises the steps:

[0054] (1) respectively take by weighing ammonium metavanadate 1.2mmol, hexahydrate cobalt nitrate 2.4mmol and 2,2-bipyridine 2.0mmol with purity greater than 99.9% for subsequent use;

[0055] (2) place the weighed cobalt nitrate hexahydrate in a beaker, add 11 ml of deionized water and stir for 8 minutes to form a homogeneous solution, add the weighed 2,2-bipyridine and ammonium metavanadate and stir for 25 minutes to obtain mixture;

[0056] (3) 2.4 mmol H 3 BO 3 Add to the above mixed solution to adjust the pH to 4, then transfer the solution to a 30ml hydrothermal reactor and heat to 160°C for 70h;

[0057] (4) cooling down to room temperature naturally, then collecting after sonicating and drying at 75°C for 10 hours to obtain the product;

[0058] (5) The product is calcined at 580°C for 3.5 hours in an air atmosphere, and the heating rate is 1.5°C / min to obtain the cobalt vanadate com...

Embodiment 3

[0062] The preparation method of cobalt vanadate compound, comprises the steps:

[0063] (1) respectively take by weighing ammonium metavanadate 1.2mmol, hexahydrate cobalt nitrate 2.4mmol and 2,2-bipyridine 2.0mmol with purity greater than 99.9% for subsequent use;

[0064] (2) place the weighed cobalt nitrate hexahydrate in a beaker, add 11 ml of deionized water and stir for 12 minutes to form a homogeneous solution, add the weighed 2,2-bipyridine and ammonium metavanadate and stir for 35 minutes to obtain mixture;

[0065] (3) 2.4 mmol H 3 BO 3 Add to the above mixed solution to adjust the pH to 6, then move the solution to a 30ml hydrothermal reactor and heat to 180°C for 74h;

[0066] (4) cooling down to room temperature naturally, and then collecting after sonicating and drying at 85° C. for 14 hours to obtain the product;

[0067] (5) calcining the product at 620° C. for 4.5 hours in an air atmosphere with a heating rate of 2.5° C. / min to obtain the cobalt vanadate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com