High-strength weather-resistant bridge steel and preparation method thereof

A bridge steel and weather-resistant technology, applied in the field of bridge steel, can solve the problems of high one-time investment and increased alloy cost, etc., and achieve the effects of low yield ratio, excellent welding performance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

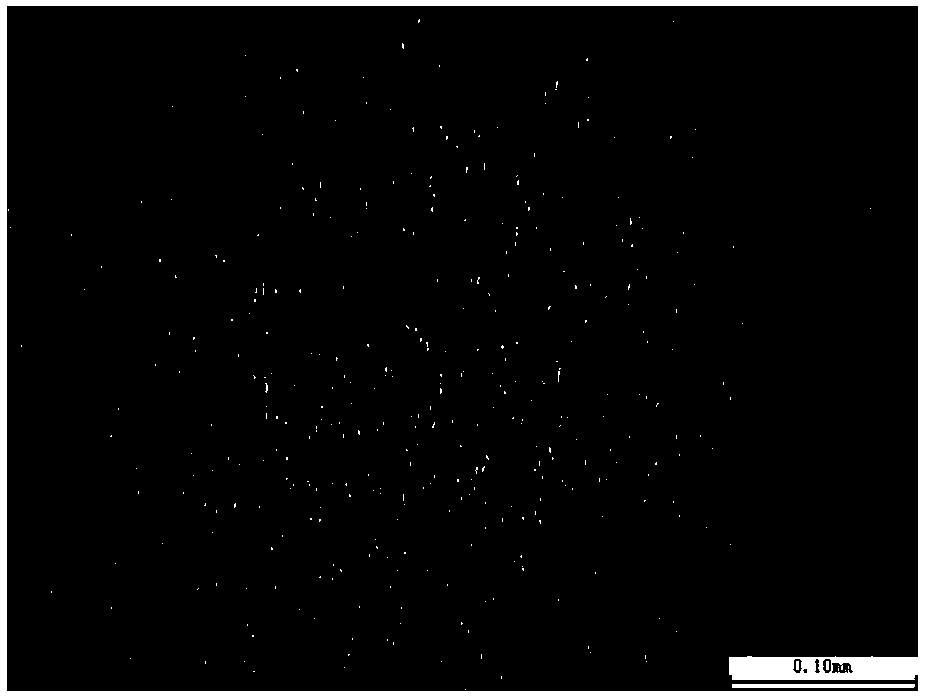

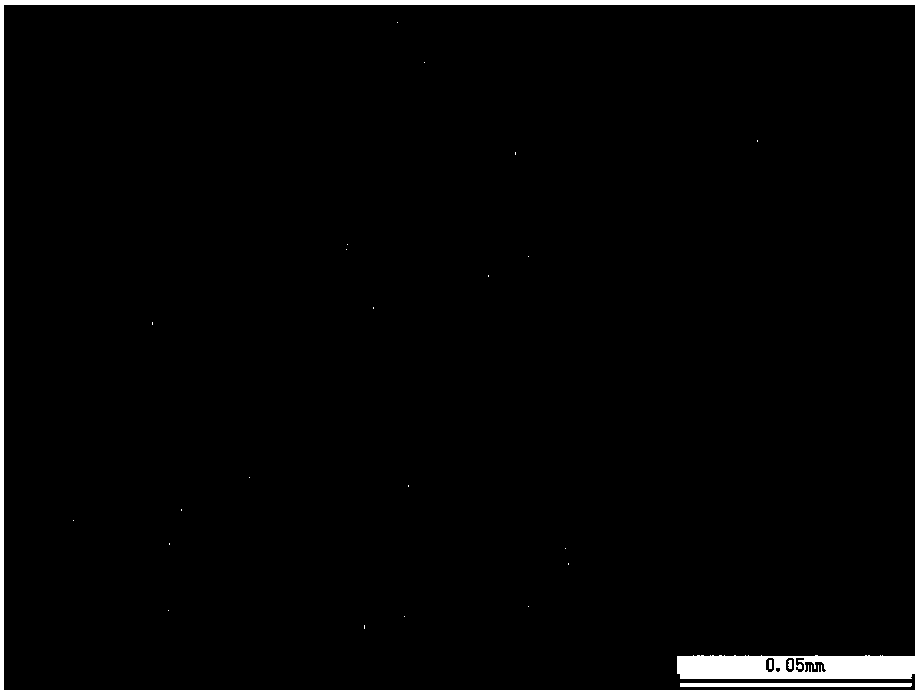

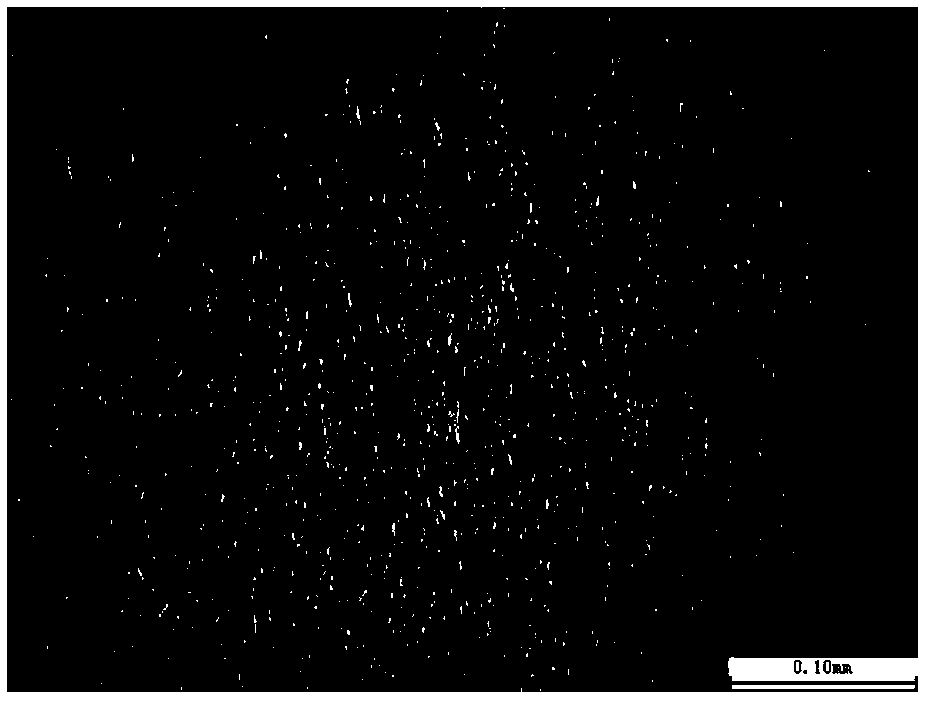

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in more detail below in conjunction with preferred embodiments of the present invention.

[0021] The chemical composition of the bridge steel of the present invention is C0.05-0.15%, Si≤0.1%, Mn≤0.1%, P0.015-0.03%, S≤0.005%, Ni1.3-1.7%, Cr0 .9-1.2%, the balance Fe is unavoidable impurities. The concrete chemical compositions of the bridge steel of each embodiment and the selected comparative examples are shown in Table 1.

[0022] Table 1. Chemical composition of high-strength weather-resistant bridge steel

[0023] Numbering

C

Si

mn

P

S

Ni

Cr

Nb

Al S

CE(IIW)

Ceq(JIS)

A

0.10

0.40

0.70

0.015

0.005

1.0

1.10

-

0.03

0.503

0.478

B

0.06

0.40

0.70

0.015

0.005

1.0

1.10

0.04

0.03

0.463

0.438

[0024] The above two kinds of billets are prepared by the rolling method designed in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com